Perovskite solar cell with zinc telluride serving as hole transporting layer and manufacturing method thereof

A technology of hole transport layer and solar cell, which is applied in the field of solar cells, can solve the problems that limit the long-term use of perovskite cells, high cost, poor stability, etc., and achieve the effect of excellent chemical stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

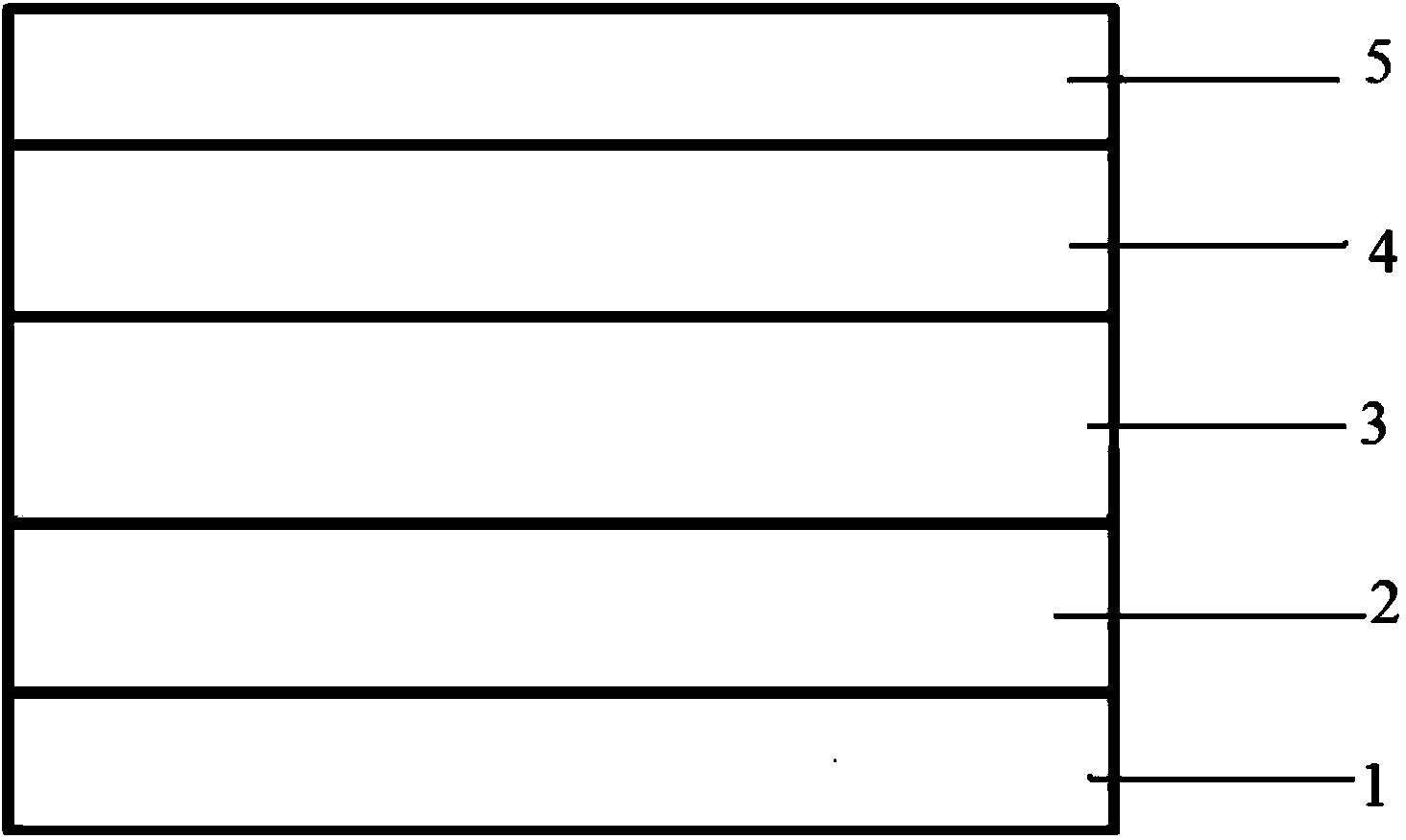

[0015] The structure of the perovskite solar cell is: a transparent conductive electrode, an electron transport layer sequentially stacked on the electrode, a perovskite structure light-absorbing layer, a zinc telluride nanoparticle hole transport layer with a thickness of 10 nm, and a gold positive electrode.

Embodiment 2

[0017] The structure of the perovskite solar cell is: a transparent conductive electrode and an electron transport layer sequentially stacked on the electrode, a perovskite structure light absorption layer, a zinc telluride hole transport layer with a thickness of 1 nm prepared by atomic layer deposition, and a silver positive electrode.

Embodiment 3

[0019] The structure of the perovskite solar cell is: a transparent conductive electrode and an electron transport layer sequentially laminated on the electrode, a perovskite structure light absorption layer, a zinc telluride hole transport layer with a thickness of 50 nm and platinum prepared by magnetron sputtering electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com