A kind of lithium battery welding and testing automation equipment

A technology of automation equipment and lithium batteries, which is applied in the direction of assembling battery machines, secondary battery manufacturing, non-aqueous electrolyte batteries, etc. , saving space cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

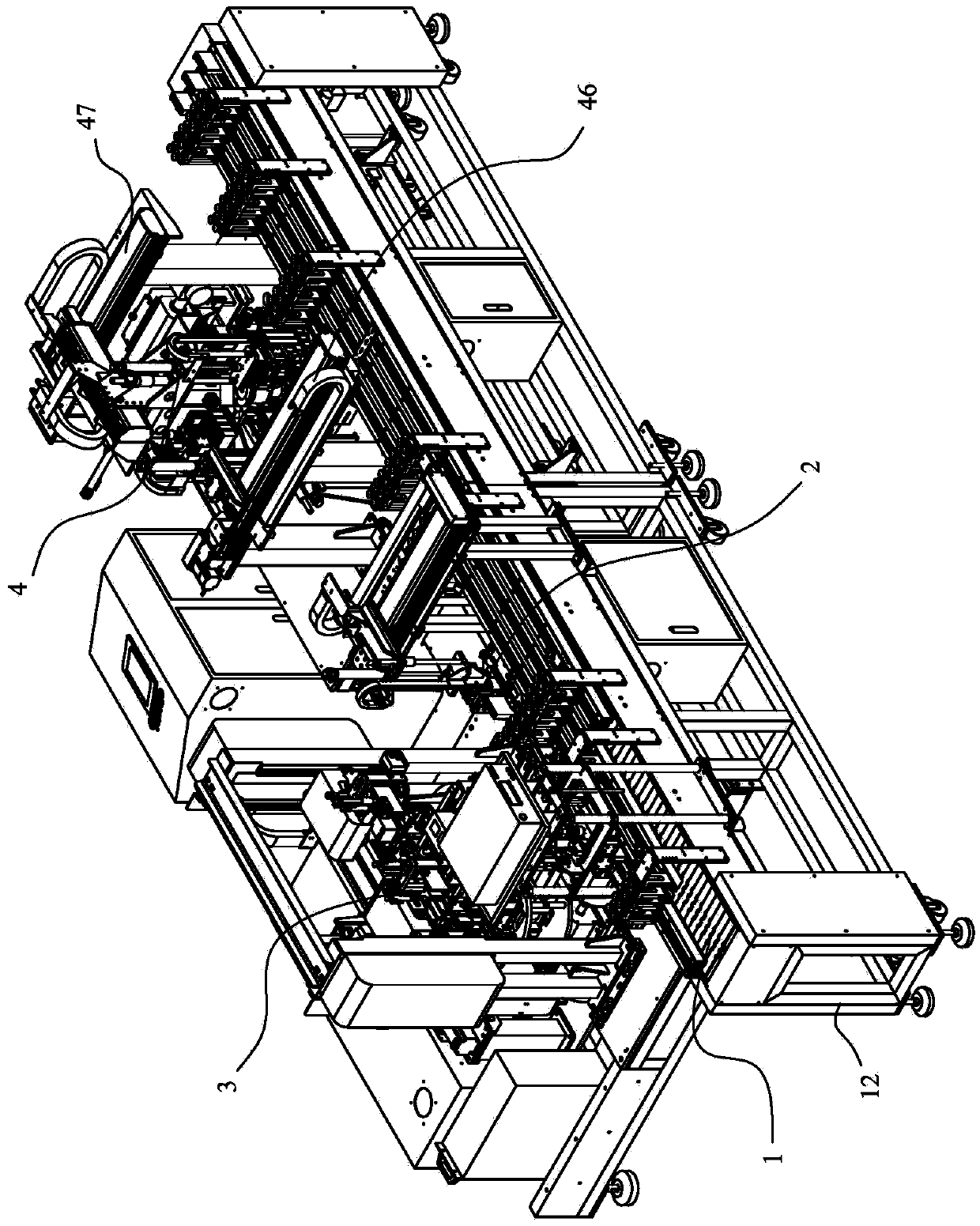

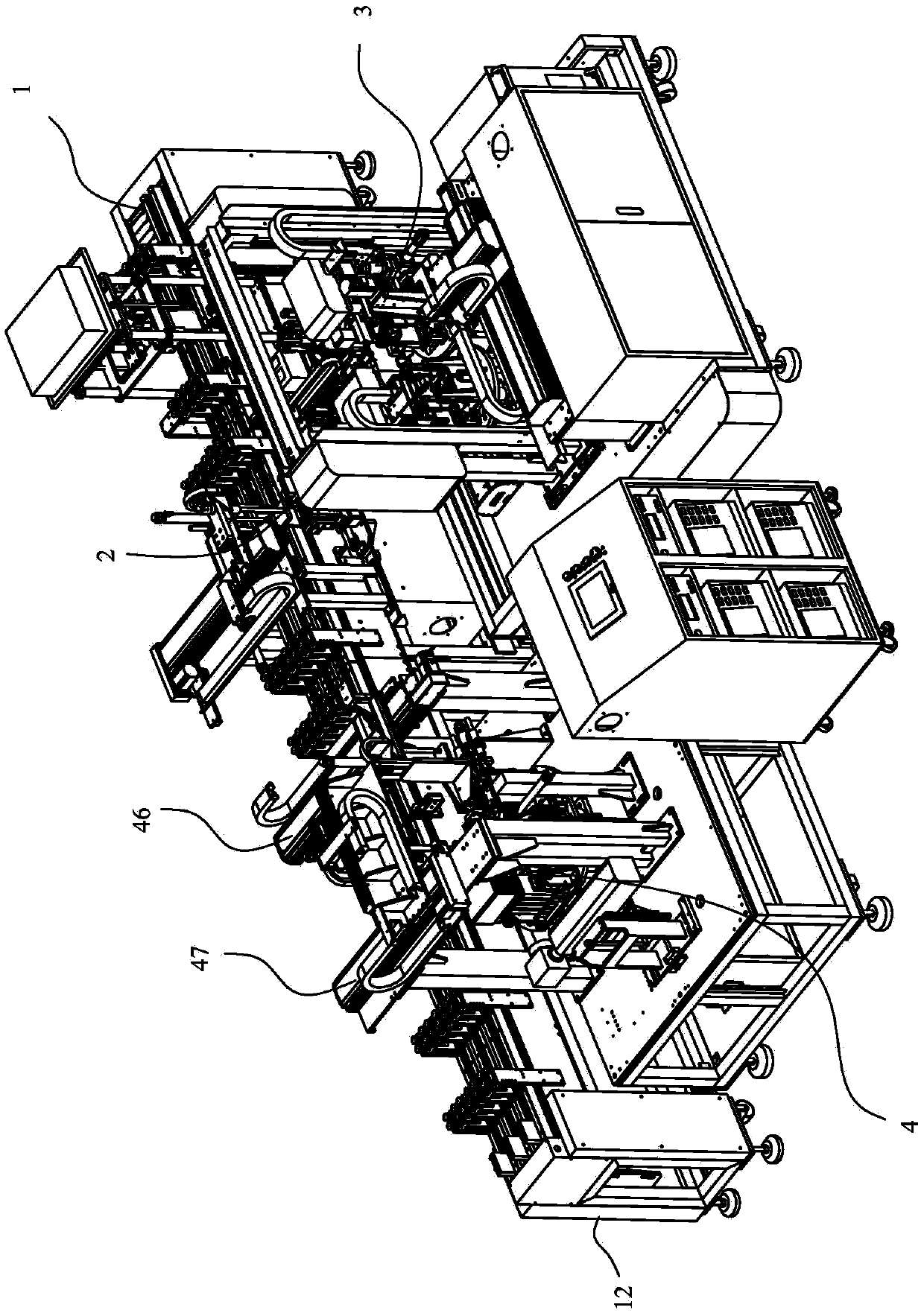

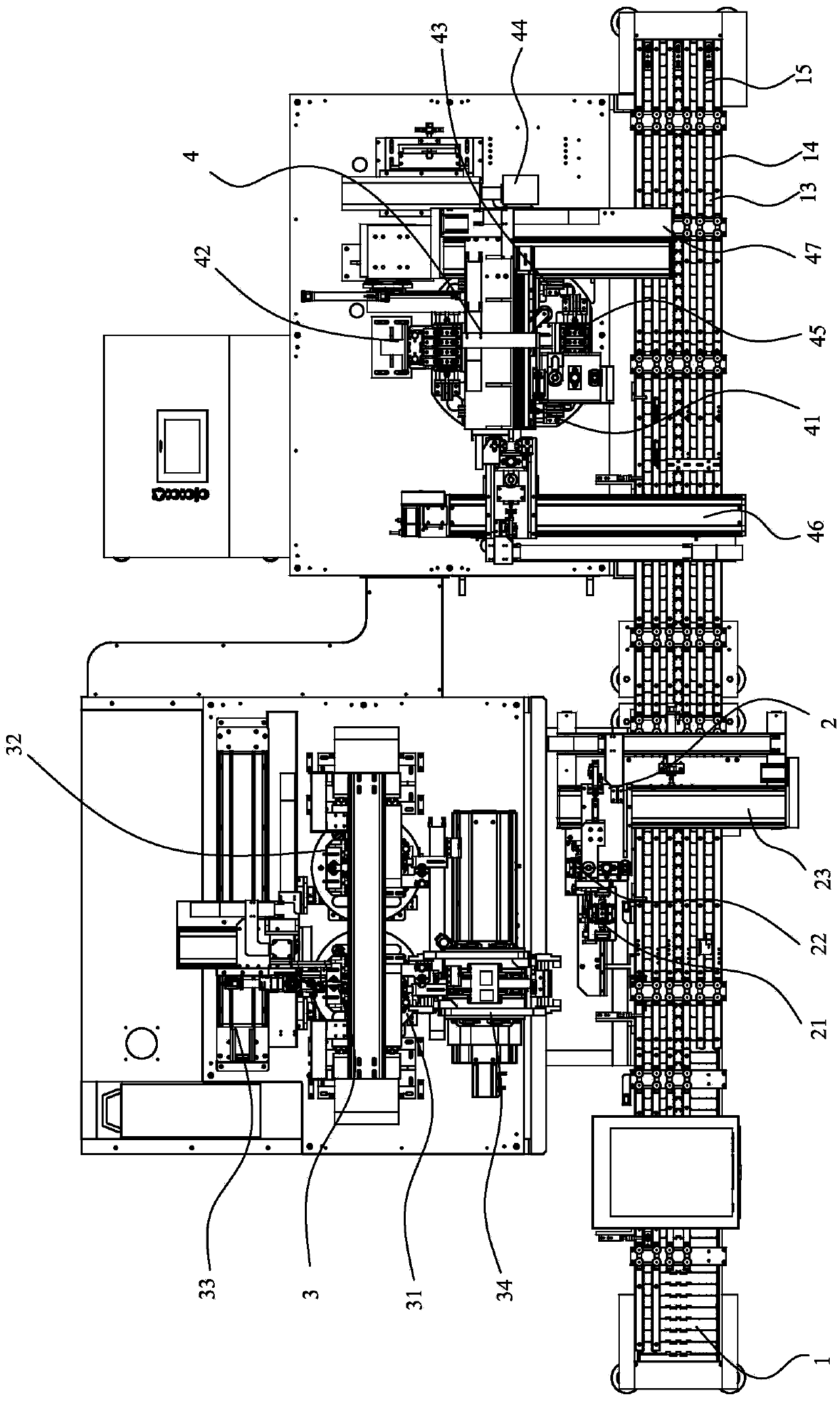

[0041] Please refer to Figure 1 to Figure 13 Shown, it has shown the concrete structure of preferred embodiment of the present invention,

[0042] A kind of automatic equipment for lithium battery welding and detection, such as figure 1 As shown, it includes a linear conveying system 1. On the same side of the conveying system 1, a welding system 3 and a detection system 4 are arranged in sequence according to the conveying direction, and a temporary storage system is arranged between the conveying system 1 and the welding system 3. Material system 2.

[0043] combine image 3As shown, the temporary storage system 2 includes a temporary storage loading station 21 , a temporary storage unloading station 22 , and a temporary storage loading and unloading manipulator 23 for retrieving and discharging materials back and forth between the two stations and the transmission system 1 .

[0044] The welding system 3 is used for welding the end cap 51 of the battery 50 and the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com