Extracting method of radix gypsophila saponin

A technology of carnation and extraction method, which is applied in the field of medicine, can solve the problems of toxicity, high energy consumption, and long time consumption, and achieve the effects of weak corrosion of equipment, simple and safe operation, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

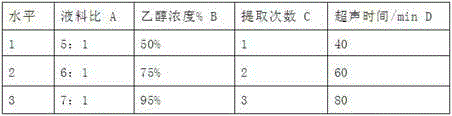

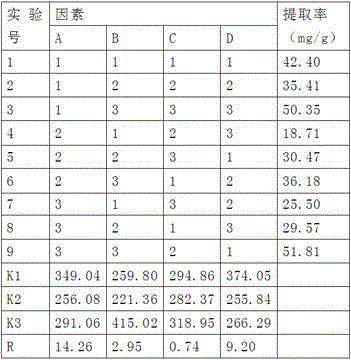

Method used

Image

Examples

Embodiment 1

[0030] ① 10g of Dianthus root is made into powder, and sieved with 80 mesh;

[0031] ②Extract with 50ml of 75% ethanol, ultrasonic for 60min, extraction times twice, temperature 60℃;

[0032] ③ Centrifuge at 2000 rpm for 10 min, and take the supernatant;

[0033] ④Dried at 80°C to form an extract, dissolved in 20ml of single distilled water, centrifuged at 2000 rpm for 10min, and took the supernatant;

[0034] ⑤ Extract 3 times with 20ml of petroleum ether, add 5% NaCl as demulsifier, and remove the lower aqueous phase;

[0035] ⑥ Pass the water phase through a D101 macroporous resin column, elute with 30% ethanol for 5 times, discard the lotion, elute with 75% ethanol for 5 times, and collect the middle 3 washes;

[0036] ⑦ The collected solution is freeze-dried to make a light brown powder, that is, total saponins;

[0037] ⑧Ultraviolet spectrophotometer 190-400nm wavelength scanning, found the absorption peak at 205nm, the total saponin content was 334.5mg.

Embodiment 2

[0039] ① 10g of Dianthus root is made into powder, and sieved with 80 mesh;

[0040] ②Extract with 70ml of 95% ethanol, ultrasonic for 40min, extraction times twice, temperature 60℃;

[0041] ③ Centrifuge at 2000 rpm for 10 min, and take the supernatant;

[0042] ④Dried at 80°C to form an extract, dissolved in 20ml of single distilled water, centrifuged at 2000 rpm for 10min, and took the supernatant;

[0043] ⑤ Extract 3 times with 20ml of petroleum ether, add 5% NaCl as demulsifier, and remove the lower aqueous phase;

[0044] ⑥Extract 3 times with 20ml of water-saturated n-butanol, and take the upper n-butanol phase;

[0045] ⑦The n-butanol phase was evaporated to dryness in a water bath in an evaporating dish to obtain a yellow-brown powder, namely total saponins;

[0046] ⑧Ultraviolet spectrophotometer 190-400nm wavelength scanning, found that there are absorption peaks at 190nm, 196nm, and 205nm, mainly at 205nm, and the total saponin content was 543.5mg.

Embodiment 3

[0048] ①Powder made from 500g of Dianthus root, and sieved with 80 mesh;

[0049] ②Extract with 2500ml of 75% ethanol, ultrasonic for 40min, extraction once, temperature 60℃;

[0050] ③ Centrifuge at 2000 rpm for 10 min, take the supernatant, and spin evaporate to recover ethanol;

[0051] ④ The concentrated solution was dried at 80°C to form an extract, dissolved in 500ml of single distilled water, centrifuged at 2000 rpm for 15min, and the supernatant was taken;

[0052] ⑤ Extract 3 times with 500ml of petroleum ether, add 10% NaCl as demulsifier, and remove the lower aqueous phase;

[0053] ⑥Water phase passed through D101 macroporous resin column, eluted with 30% ethanol for 5 times, discarded the lotion, eluted with 75% ethanol again for 5 times, collected 4 times of lotion;

[0054] ⑦ The collected solution is rotary evaporated to recover ethanol, and the concentrated solution is freeze-dried to make a light brown powder, namely total saponins;

[0055] ⑧Ultraviolet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com