Preparation method of metal-organic framework zif-8 membrane-coated supported noble metal efficient core-shell catalyst with tunable selectivity

A technology of noble metal catalysts and metal-organic frameworks, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve wide application prospects and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

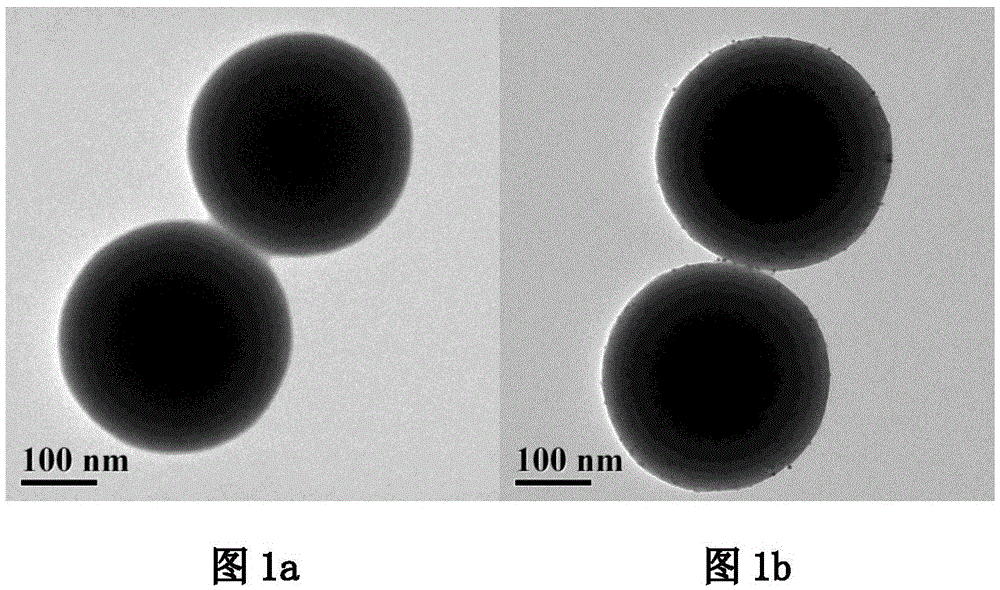

[0029] (1) Preparation of Pd nanoparticles

[0030] First prepare 2mMH 2 PdCl 4 aqueous solution, and then with PVP, H 2 After mixing O and HCl, heat to boiling, add ethanol immediately, and reflux for 3h;

[0031] (2) SiO 2 Preparation of vector

[0032] According to stober method, using TEOS as silicon source, NH 4 OH is used as a catalyst, and it is hydrolyzed at room temperature for 1 hour under the mixed system of ethanol / water;

[0033](3) Combine the Pd nanoparticles obtained by method (1) with the SiO obtained by method (2) 2 Mix at room temperature for 24 hours to obtain Pd / SiO 2 catalyst;

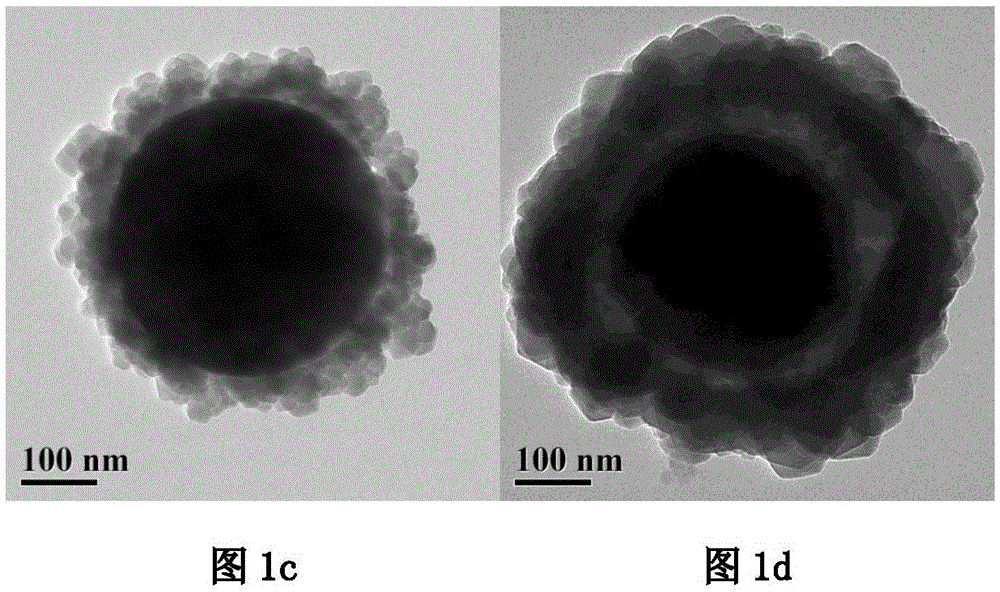

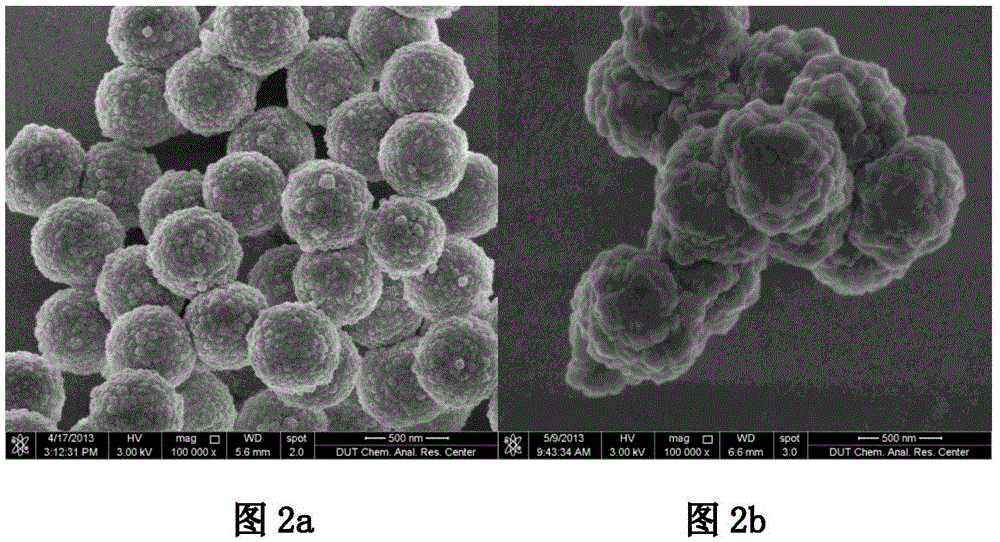

[0034] (4) Pd / SiO obtained by method (3) 2 Mix the aqueous solution with the PDDA aqueous solution, let it stand at room temperature for 30 minutes, and then centrifugally wash it with deionized water for several times; then mix it with the PSS aqueous solution at room temperature for 30 minutes, and then centrifugally wash it with deionized water and methanol for several...

Embodiment 2

[0038] (1) Preparation of Pd nanoparticles

[0039] First prepare 2mMH 2 PdCl 4 aqueous solution, and then with PVP, H 2 After mixing O and HCl, heat to boiling, add ethanol immediately, and reflux for 3h;

[0040] (2) SiO 2 Preparation of vector

[0041] According to stober method, using TEOS as silicon source, NH 4 OH is used as a catalyst, and it is hydrolyzed at room temperature for 1 hour under the mixed system of ethanol / water;

[0042] (3) Combine the Pd nanoparticles obtained by method (1) with the SiO obtained by method (2) 2 Mix at room temperature for 24 hours to obtain Pd / SiO 2 catalyst;

[0043] (4) The catalyst obtained in method (3) was vacuum-dried overnight at 80°C and placed in a desiccator for testing.

Embodiment 3

[0045] (1) Preparation of Pd nanoparticles

[0046] First prepare 2mMH 2 PdCl 4 aqueous solution, and then with PVP, H 2 After mixing O and HCl, heat to boiling, add ethanol immediately, and reflux for 3h;

[0047] (2) SiO 2 Preparation of vector

[0048] According to stober method, using TEOS as silicon source, NH 4 OH is used as a catalyst, and it is hydrolyzed at room temperature for 1 hour under the mixed system of ethanol / water;

[0049] (3) Combine the Pd nanoparticles obtained by method (1) with the SiO obtained by method (2) 2 Mix at room temperature for 24 hours to obtain Pd / SiO 2 catalyst;

[0050] (4) Pd / SiO obtained by method (3) 2 Mix the aqueous solution with the PDDA aqueous solution, let it stand at room temperature for 30 minutes, and then centrifugally wash it with deionized water for several times; then mix it with the PSS aqueous solution at room temperature for 30 minutes, and then centrifugally wash it with deionized water and methanol for severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com