Process for producing ethyltoluene

A technology for ethyl toluene and toluene, applied in the field of ethyl toluene production, can solve the problems of inability to precisely adjust the ratio, short regeneration period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Catalyst preparation: 65 parts of SiO 2 / Al 2 O 3 The original HZSM-5 powder with a molar ratio of 90 and 35 parts of binder alumina were kneaded into molding, and the extruded strip product was dried overnight and then calcined in a muffle furnace at 550°C for 6 hours to remove the residual template agent. The obtained samples were impregnated with an aqueous solution of ammonium dihydrogen phosphate with a concentration of 2.0-5.0 wt%, soaked for 2 hours, filtered and dried overnight, and then roasted in a muffle furnace at 550 °C for 6 hours to prepare phosphorus-modified samples. Add the silicone oil solution with a concentration of 10-50wt% to the above-mentioned phosphorus-modified samples, soak for 2 hours, filter and dry overnight, and bake them in a muffle furnace at 550 °C for 6 hours to make silicon-modified or phosphorus-silicon modified samples sample. In the silicone oil solution, the content of methyl silicone oil is 0-40 wt %, the content of amino sil...

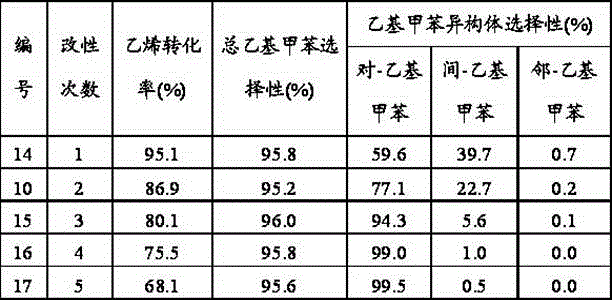

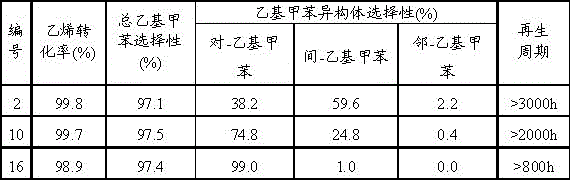

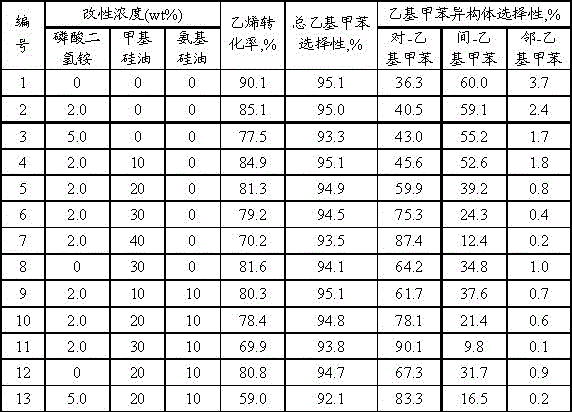

Embodiment 2

[0023] Catalyst preparation: 65 parts of SiO 2 / Al 2 O 3 The original HZSM-5 powder with a molar ratio of 90 and 35 parts of binder alumina were kneaded into molding, and the extruded strip product was dried overnight and then calcined in a muffle furnace at 550°C for 6 hours to remove the residual template agent. The obtained sample was impregnated with an aqueous solution of ammonium dihydrogen phosphate with a concentration of 2.0 wt%, soaked for 2 hours, filtered and dried overnight, and then calcined in a muffle furnace at 550 °C for 6 hours to prepare a phosphorus-modified sample. A silicone oil solution containing 20wt% of methyl silicone oil and 10wt% of amino silicone oil was added to the above phosphorus-modified sample, immersed for 2 hours, filtered and dried overnight, and then calcined at 550°C for 6 hours in a muffle furnace to prepare silicon modification. or phosphorus-silicon modified samples. The solvent is n-hexane. The modification times of silicone oi...

Embodiment 3

[0025] The catalyst sample in [Example 1] was loaded into the fixed bed reactor, and the loading amount was 6.5 g. The reaction was carried out using toluene (>99%) and polymer-grade ethylene as raw materials, with an ethylene flow rate of 13.4 g / h and a toluene flow rate of 176.0 g / h. The molar ratio of toluene and ethylene was 4.0 and the total mass space velocity was 29.2 hours -1 , the reaction temperature was 360 °C, and the pressure was 0.5 MPa. The results of the reaction conversion rate and the selectivity of various products are shown in Table 1. Among them, the selectivity of the ortho, meta and para ethyl toluene products has a wide distribution range, which can meet the different requirements of different enterprise users on the selectivity.

[0026] Table 1 - Reaction performance under different modification conditions

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com