Method for using microbial flotation method to separate pyrites from arsenopyrites

A technology for microorganisms and pyrite, applied in the fields of mineral processing and microorganisms, can solve problems such as separation difficulties, and achieve the effects of advanced method technology, effective separation and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

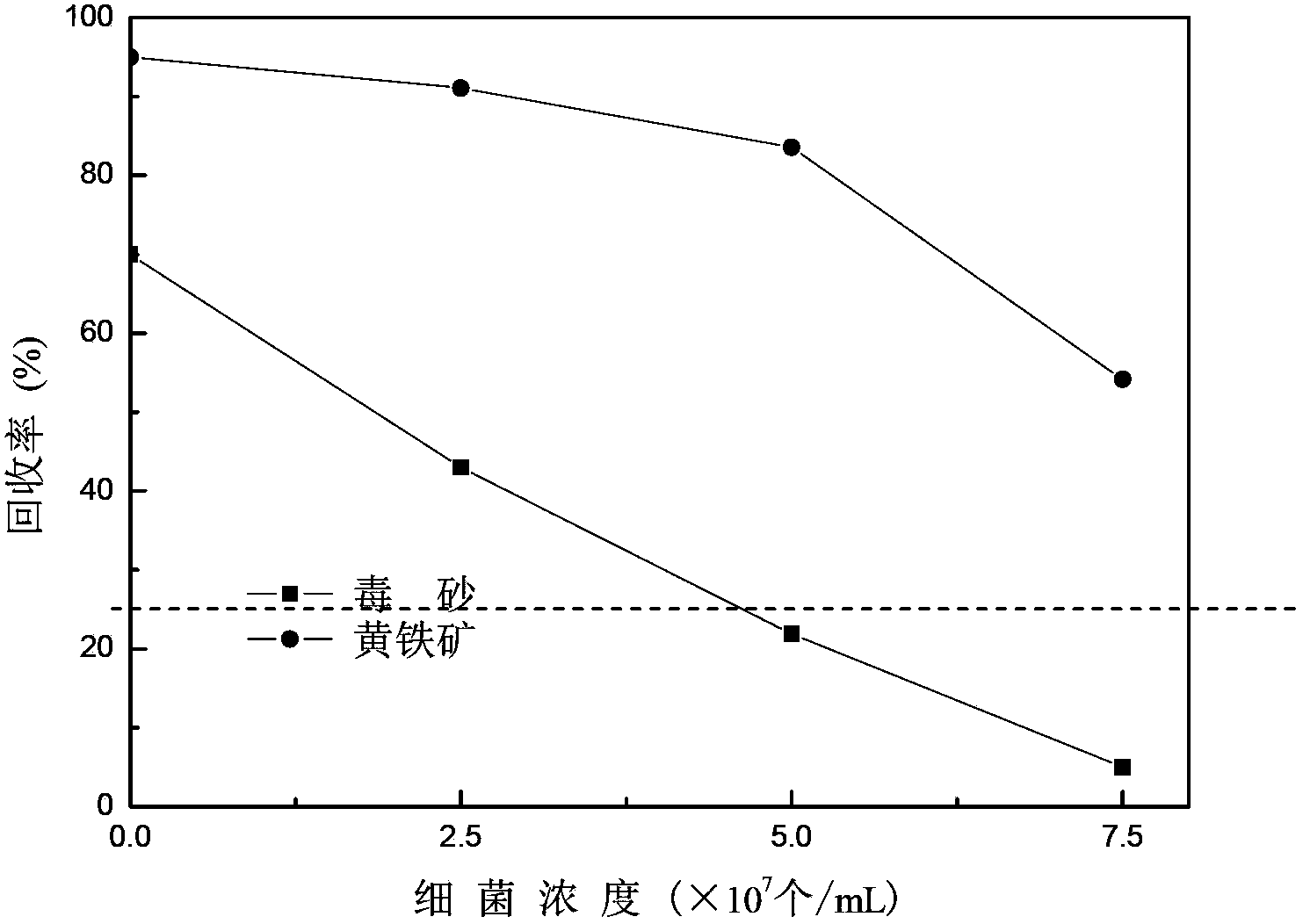

[0022] Example 1 The separation of pyrite and arsenopyrite under different microbial concentrations

[0023] Under the condition that the test water is deionized water and natural pH, 2.0g of artificial mixed ore mixed with pyrite and arsenopyrite at a mass ratio of 1:1 is taken, and it is cleaned by ultrasonic wave for 5 minutes, and then treated with bacterial solutions of different concentrations for 5 minutes. Then quickly transfer to the flotation cell, add the activator copper sulfate of 6mg / L, the collector of 7.6mg / L and the frother of 2.0mg / L and carry out flotation, investigate the impact of bacterial concentration on pyrite and arsenopyrite Influence of bioflotation separation effect. The relationship between the recovery rate of pyrite and arsenopyrite and the bacterial concentration is as follows figure 1 shown.

[0024] from figure 1 It can be seen that with the increase of the bacterial concentration, the recovery rates of pyrite and arsenopyrite are obviousl...

Embodiment 2

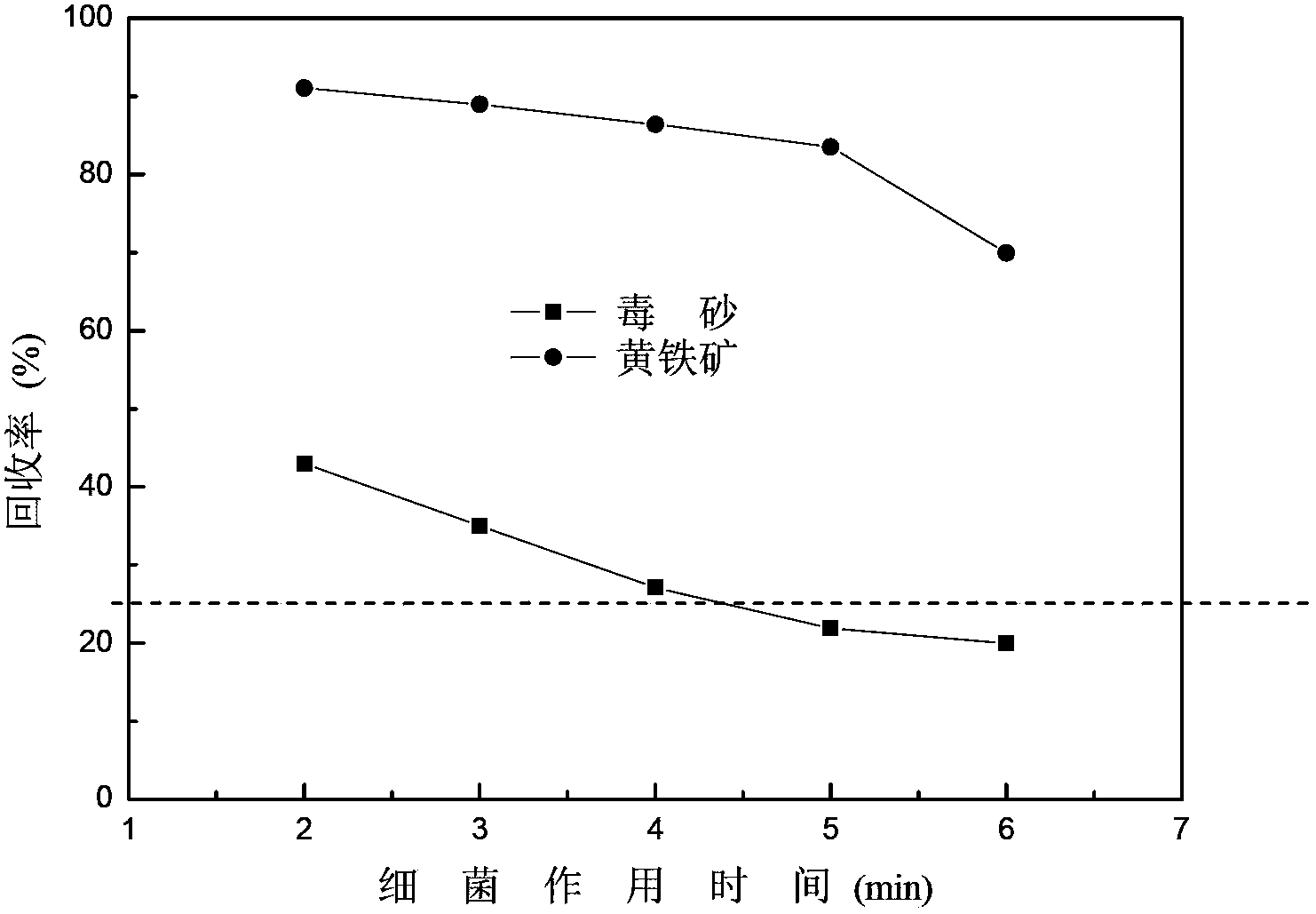

[0025] Example 2 Separation results of pyrite and arsenopyrite interacting with bacteria for different times

[0026] Under the condition that the test water is deionized water and natural pH, take 2.0g of artificial mixed ore mixed with pyrite and arsenopyrite in a mass ratio of 1:1, and then ultrasonically clean it for 5min, with a concentration of 5.0×10 7 Each / mL bacterial solution acts for different periods of time, and then quickly transferred to the flotation tank, adding 6mg / L activator copper sulfate, 7.6mg / L collector and 2.0mg / L foaming agent Flotation, to investigate the effect of bacterial action time on pyrite and arsenopyrite biological flotation separation effect. The relationship between the recovery rate of pyrite and arsenopyrite and the action time is as follows figure 2 shown.

[0027] from figure 2 It can be seen that with the prolongation of the bacterial action time, the recovery rates of pyrite and arsenopyrite are obviously decreasing, but in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com