Amide compound and preparation method and application thereof

An amide compound and reaction technology, applied in the field of pesticides, can solve the problems of poor control effect on broad-leaved weeds, and achieve the effect of simple operation, high yield and good herbicidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

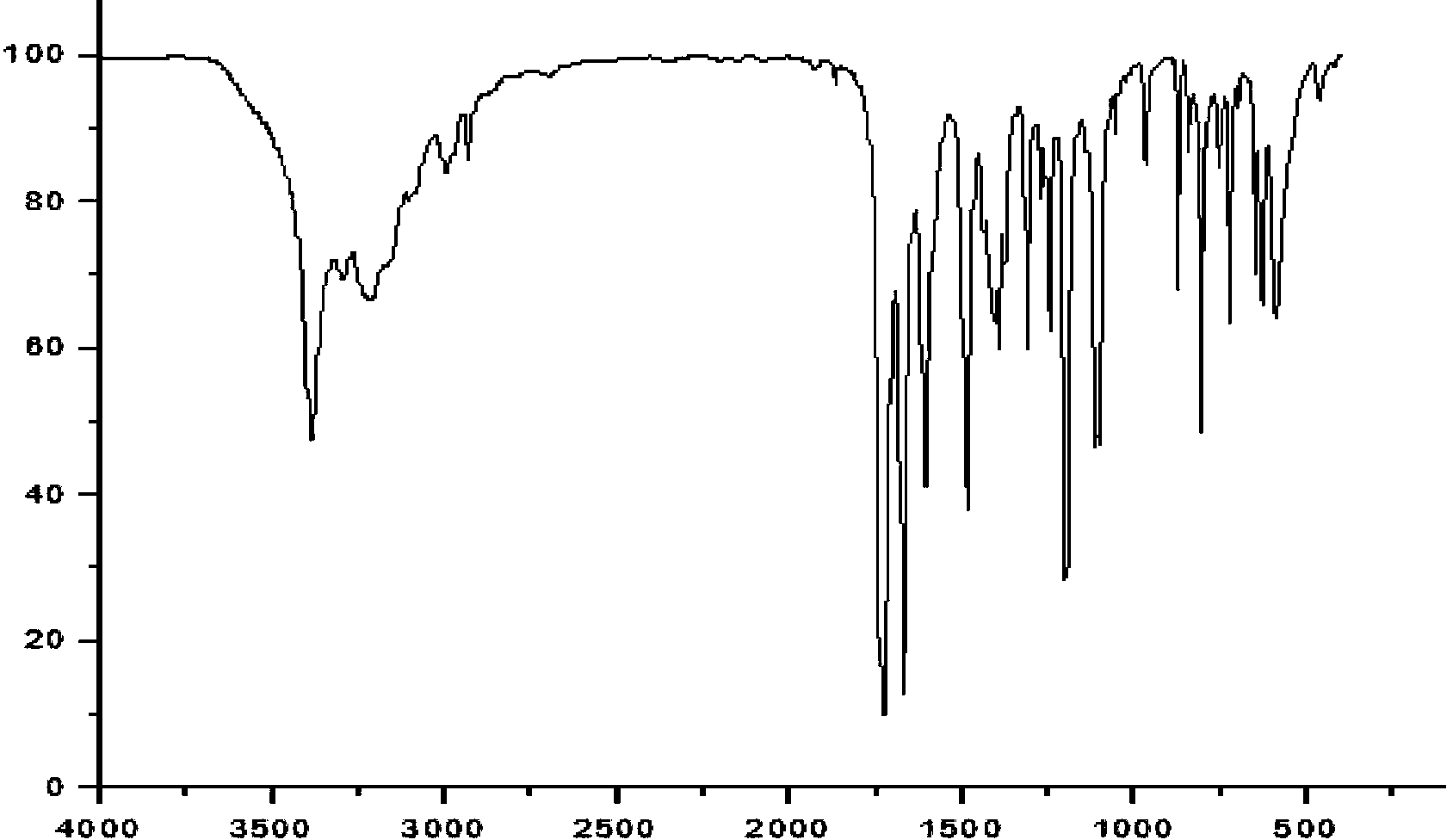

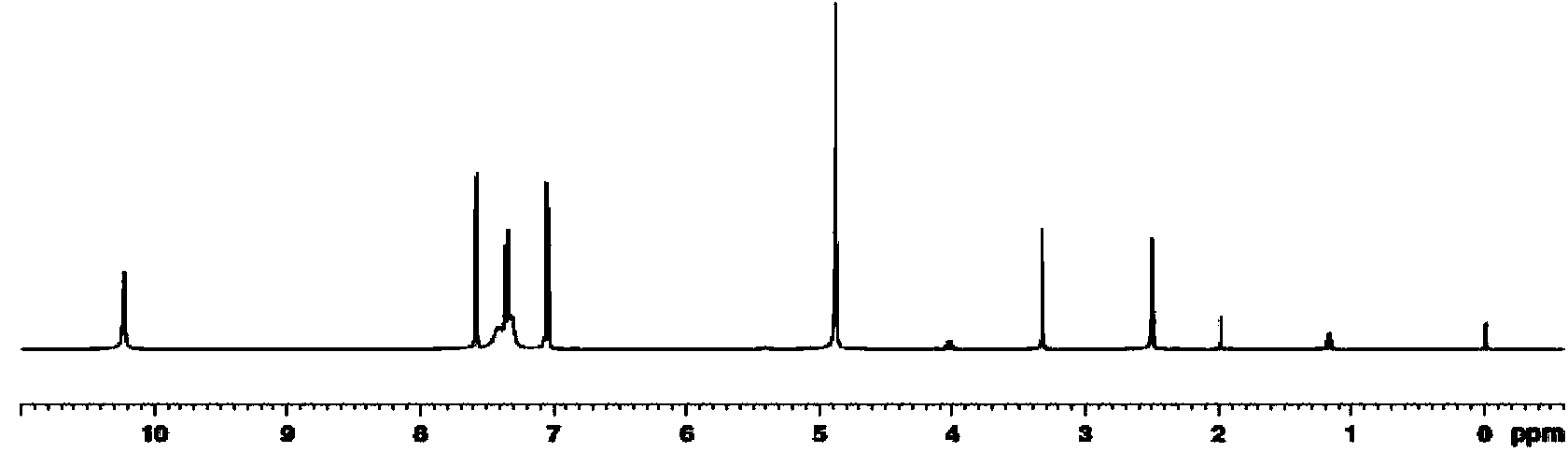

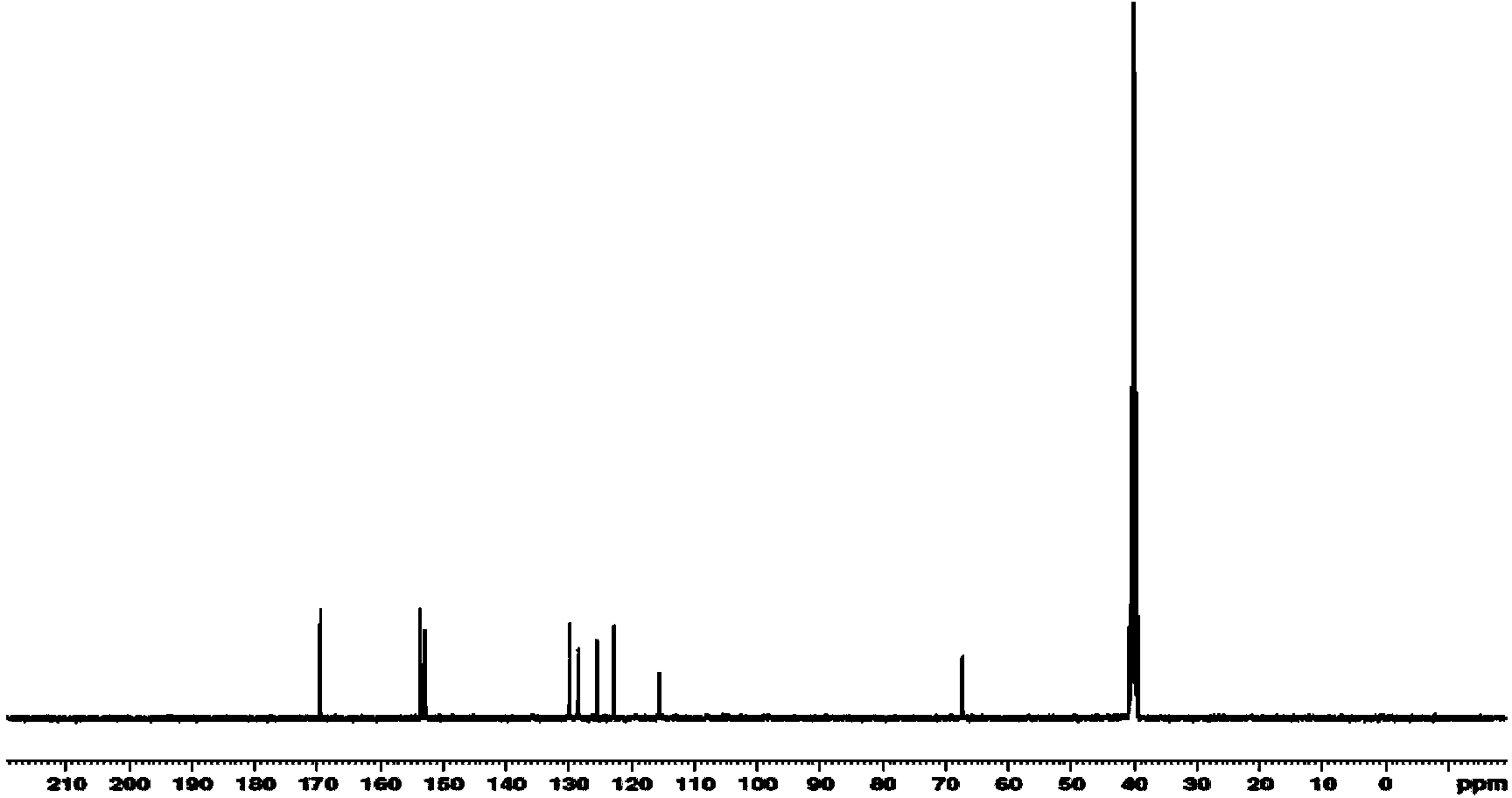

Image

Examples

Embodiment 1

[0021] (1) Synthesis of compound I

[0022] Add 2 g of 2,4-dichlorophenoxyacetic acid and 8.8 mL of thionyl chloride into a 50 mL single-necked round-bottom flask, and carry out a reflux reaction at about 67°C under a magnetic stirrer for 3 hours to obtain a pungent PALE YELLOW LIQUID WITH ODOR. The reaction solution was distilled under reduced pressure in a water bath at 40°C under a vacuum of -0.07 Mpa to remove excess thionyl chloride to obtain 1.84 g of light yellow oily liquid, which was 2,4-dichlorophenoxyacetyl chloride (compound I: ).

[0023] (2) Synthesis of Compound II

[0024] Dissolve 1.84 g of 2,4-dichlorophenoxyacetyl chloride in 10 mL of tetrahydrofuran solvent, add 0.5 g of urea, heat on a constant temperature heating magnetic stirrer, and reflux at 70 °C for 5 h to obtain a yellow-white emulsion. Distill under reduced pressure in a water bath at 40°C under a vacuum of -0.07 Mpa to remove tetrahydrofuran and obtain white crystals. Dissolve the crystals wi...

Embodiment 2

[0026] Dissolve 1.84 g of 2,4-dichlorophenoxyacetyl chloride in 3.5 mL of pyridine solvent, add 0.75 g of urea, heat to 90°C in a water bath under a magnetic stirrer, and reflux for 5 hours to obtain a reddish-brown sticky substance. Distill under reduced pressure in a water bath at 70°C and a vacuum of -0.07 Mpa to remove pyridine to obtain a dark red solid, which was extracted 5 times with ethyl acetate. Ethyl acetate was removed by distillation under pressure to obtain white crystals. Dissolve the crystals with 20 mL of pyridine under the system conditions of 60°C, remove incompatible impurities by hot suction filtration, carry out vacuum distillation again at 75°C in a water bath, and vacuum -0.07 Mpa to remove pyridine, and recondense in dichloromethane to obtain the target product ( Compound II) 1.07 g, the yield is 60%.

Embodiment 3

[0028] Dissolve 1.84 g of 2,4-dichlorophenoxyacetyl chloride in 5 mL of tetrahydrofuran solvent, add 1.5 g of urea, heat to 70 °C, stir and reflux for 5 h, and obtain a yellow-white emulsion. Distill under reduced pressure in a water bath at 40°C under a vacuum of -0.07 Mpa to remove tetrahydrofuran and obtain white crystals. Dissolve the crystals with 20 mL of pyridine under the system conditions of 60°C, remove incompatible impurities by hot suction filtration, conduct vacuum distillation again at 75°C in a water bath, and vacuum degree -0.07 Mpa to remove pyridine, recrystallize in dichloromethane, and dry to obtain The target product (compound II) was 1.25 g, and the yield was 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com