Axisymmetric external axially-spiral-up fin device

A technology of external rotation and thread rotation, which is applied in the direction of drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of limited length, failure of overall mechanism function, low efficiency and unfavorable improvement of tunneling speed, etc., to cope with extreme conditions and equipment failures The effect of low rate and good drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

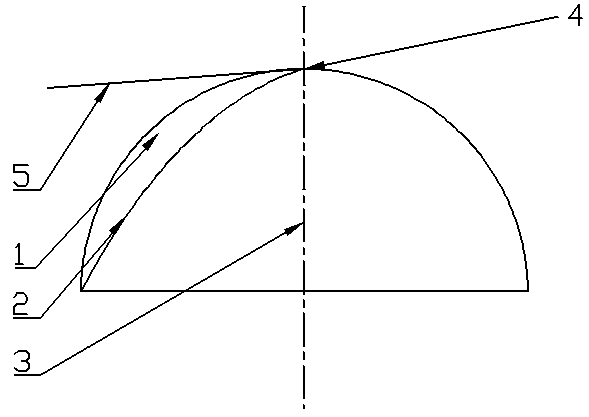

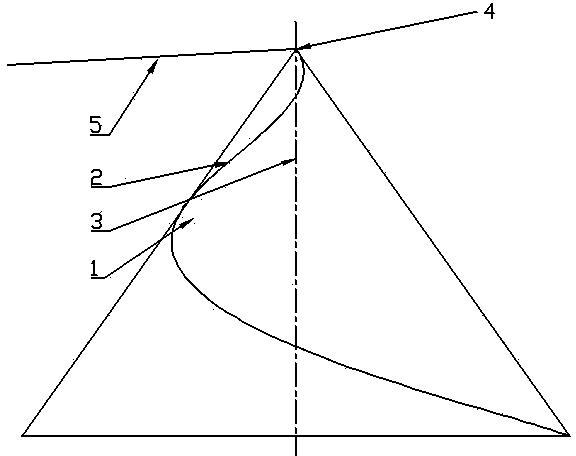

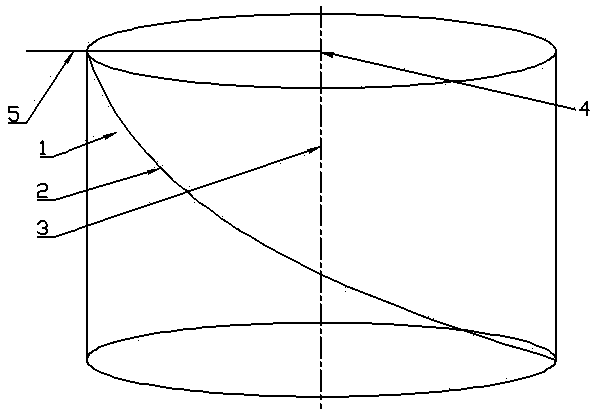

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6 show the external rotation of Aibot, which consists of attachment body 1, attachment rotation line 2, axis 3, apex 4, external rotation line 5, blade tip 6, blade body 7, external rotation body 8, The externally spinning tail consists of 9.

[0026] Such as figure 1 , 2 As shown in , 3, the construction principle of Aibote's external rotation: it is composed of attachment body 1, attachment rotation line 2, axis 3, apex 4, and external rotation line 5; where attachment body 1 is the device attached to the external rotation body 8, and the attachment The body 1 is composed of a vertebral body, a partial sphere, and a cylinder, and is an axisymmetric structure; the attachment spiral 2 is a line that starts from the apex of the side of the attachment body 1, attaches to the side of the attachment body 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com