Low pressure filtration heat exchanger

A heat exchanger and low-pressure technology, which is applied in the field of low-pressure filter heat exchangers, can solve the problems of increasing the difficulty of opening nozzles, and achieve the effects of increased working life, long contact time, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

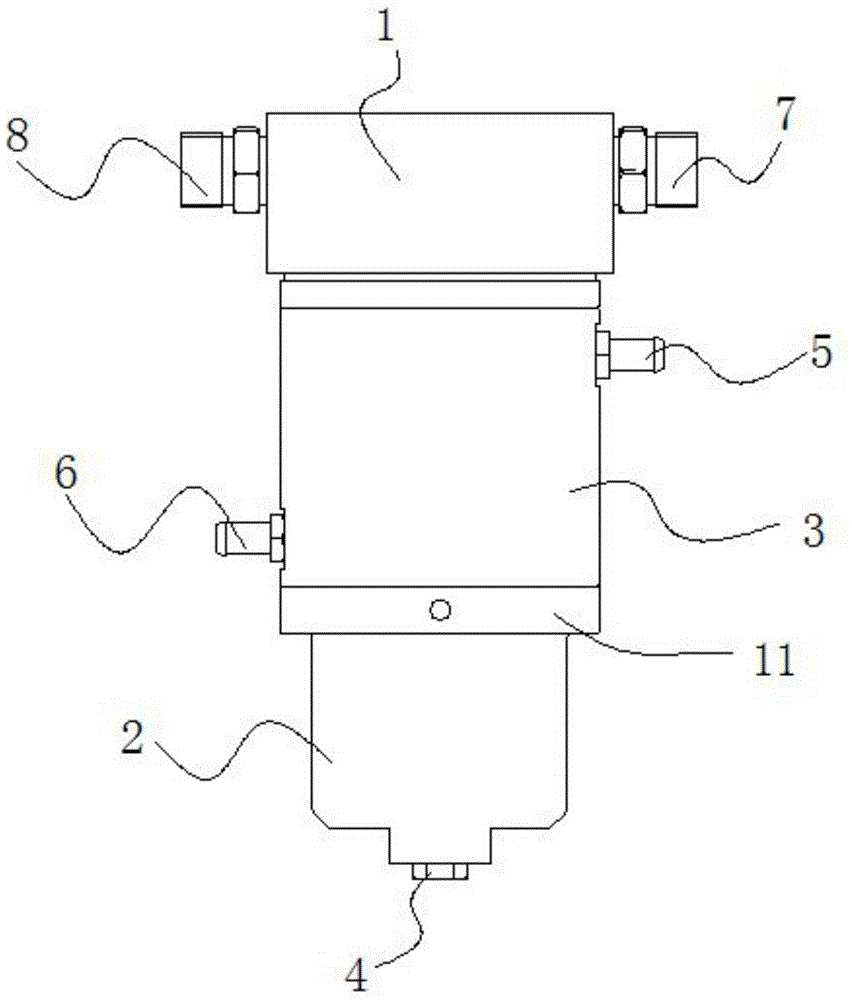

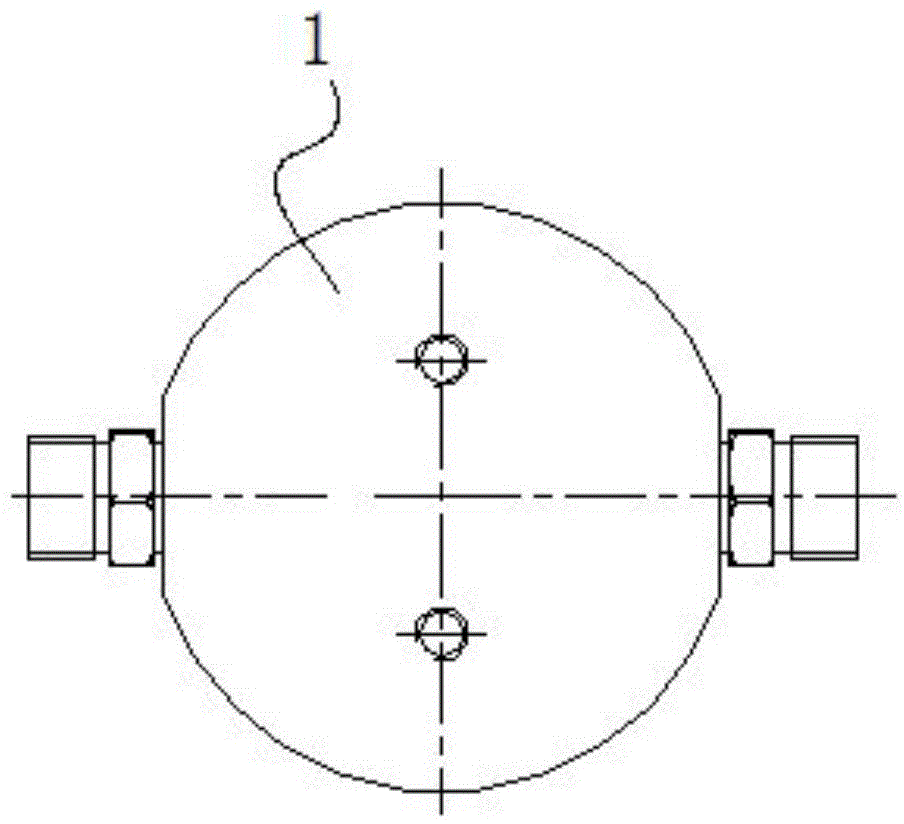

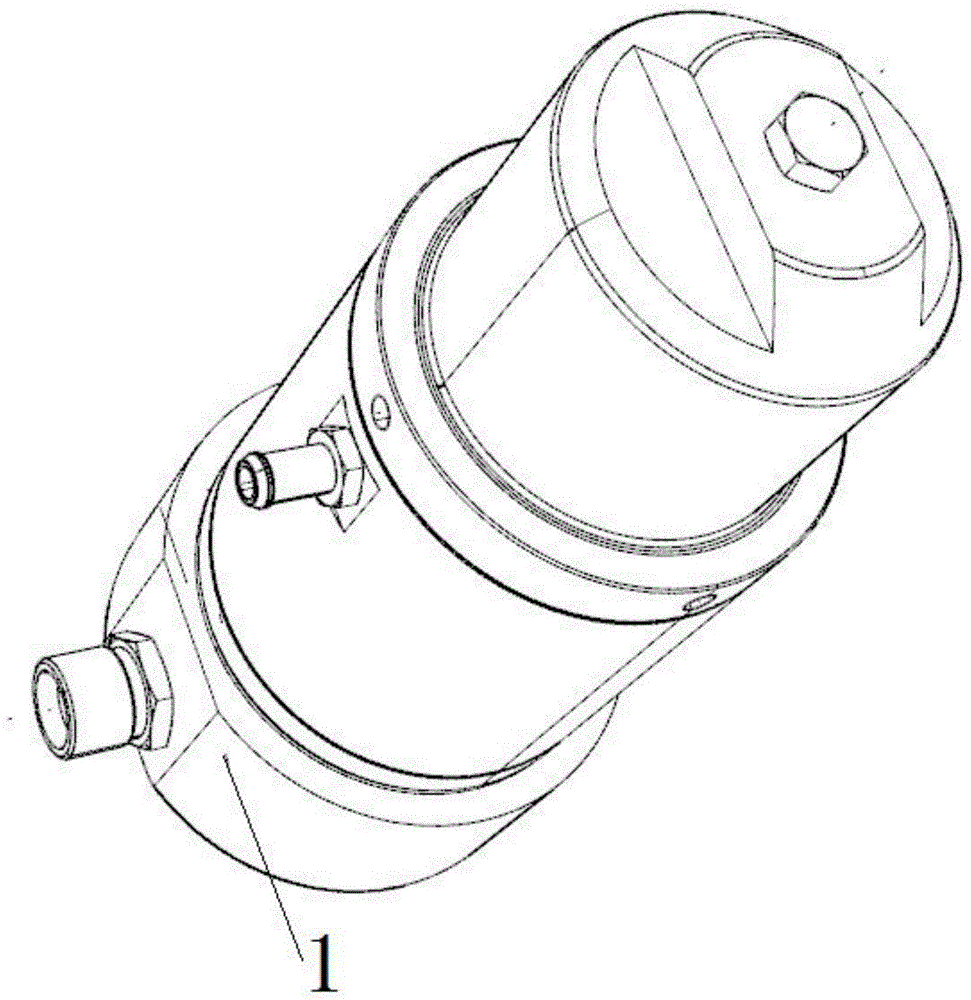

[0040] figure 1 It is a front view of the low-pressure filter heat exchanger of the present invention, wherein the symbol 1 is the upper shell unit of the low-pressure filter heat exchanger, which is generally a cylindrical structure, and the upper shell unit of the cylindrical structure has a cavity inside Body, and the lower part is open, which is convenient for docking the lower housing unit. The upper housing unit 1 consists of an annular housing wall 1a and an upper cover portion 1b forming a bottomed cylindrical shape with an open end (see Figure 4~8 ), the inner wall of the upper housing unit is provided with an internal thread structure for assembly near the opening. The gas inlet end 7 and the gas outlet end 8 arranged coaxially are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com