Aggregate device of rotary kiln

A collecting device and rotary kiln technology, which is applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of no collecting device for iron slag and unfavorable resources for subsequent utilization, so as to achieve easy utilization, convenient classification, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

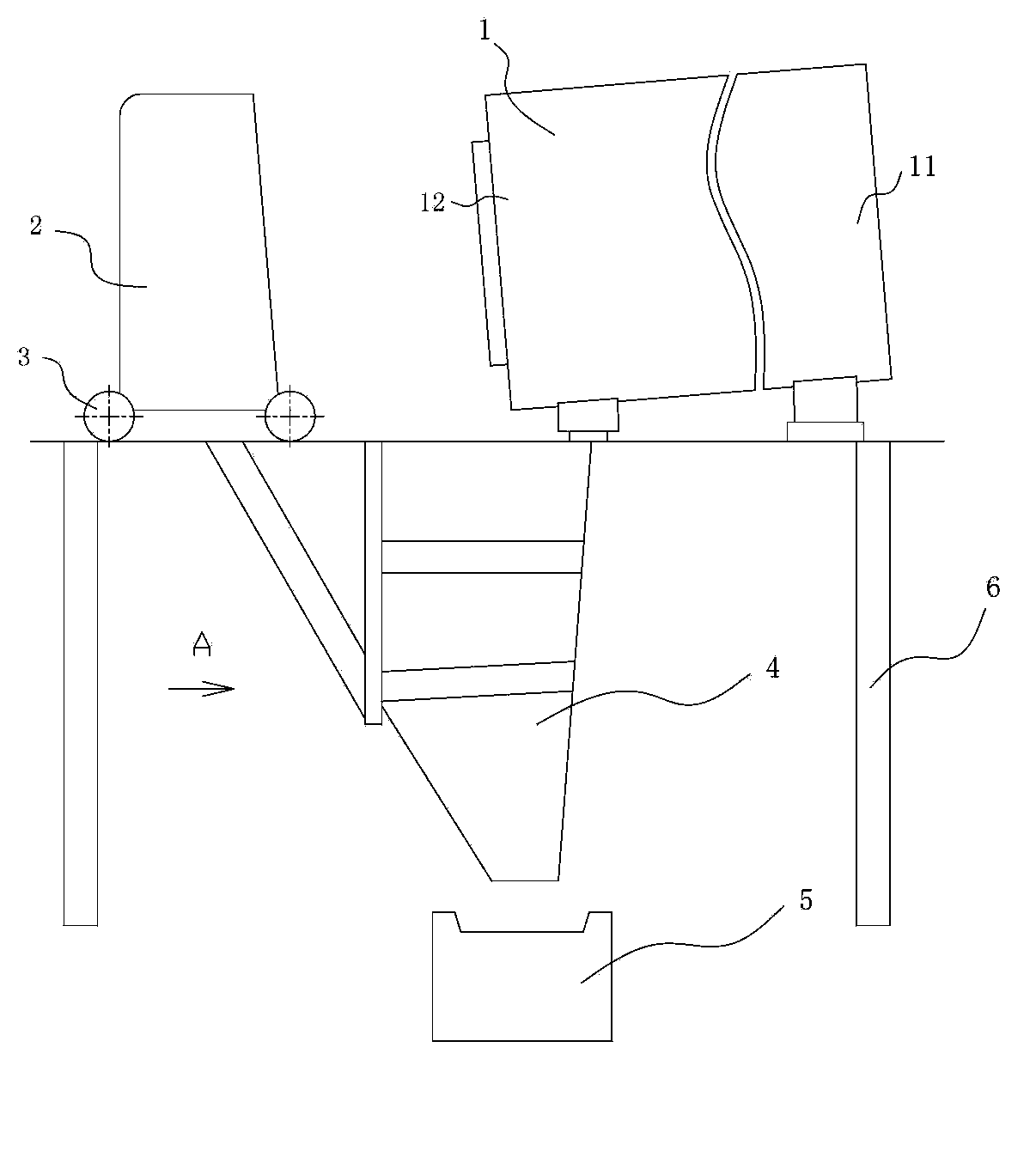

[0011] The present invention as Figure 1-2 As shown, the rotary kiln includes a rotary kiln body 1 and a kiln head cover body 2, and the rotary kiln body 1 is arranged on a horizontal support 6; the rotary kiln body 1 has a feed port 11 and a discharge port 12; The collection device 4 is located below the discharge port 12 of the rotary kiln body. The collection device 4 includes a collection bin 42 and a transmission device 5. The collection bin 42 is funnel-shaped with a large upper part and a smaller bottom part. The conveying device 5 is arranged below the collection bin 42 . During operation, a kiln head cover 2 is provided at the discharge port 12 of the rotary kiln body, and a wheel 3 is provided at the lower part of the kiln head cover 2, so that the opening and closing of the rotary kiln body 1 can be realized conveniently and quickly.

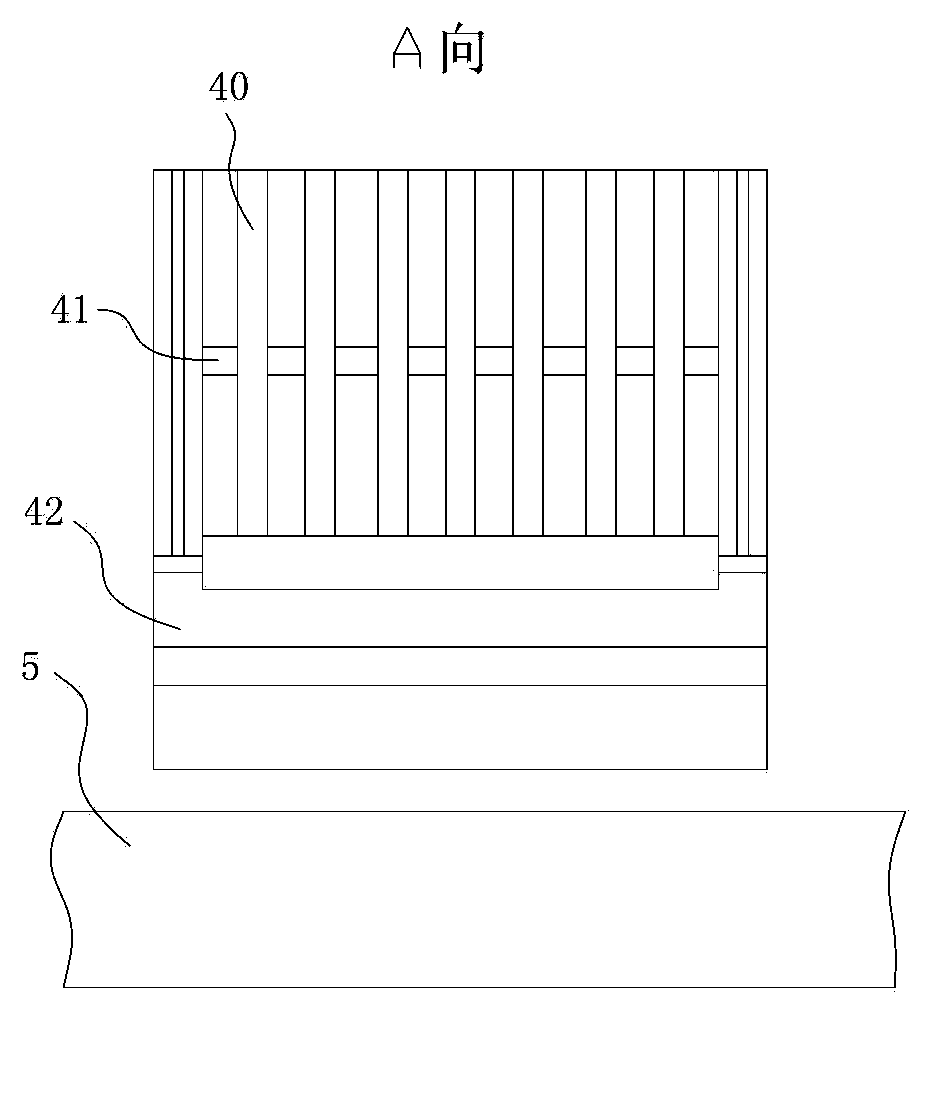

[0012] A number of grating rods 40 are evenly arranged on the bin mouth of the collecting bin 42 , and the orientation of the grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com