Track traffic rotation speed sensor based on magnetism principle

A speed sensor, rail transit technology, applied in linear/angular velocity measurement, instrument, speed/acceleration/shock measurement, etc., can solve the problem of inability to read the speed signal of the magnetoelectric speed sensor, increase safety hazards, increase operating costs, etc. To achieve the effect of reliable and flexible connection, improved anti-interference, high production and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

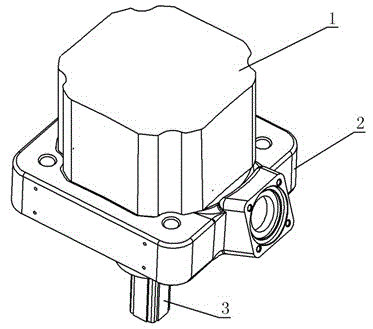

[0033] Such as figure 1 The magnetic principle-based speed sensor used for rail transit is shown, the cover body 1 is fixed above the sensor seat 2, the shaft assembly 3 is fixed below the seat 2, and the space enclosed by the seat 2 and the cover body 1 Set up the speed measuring part of the sensor.

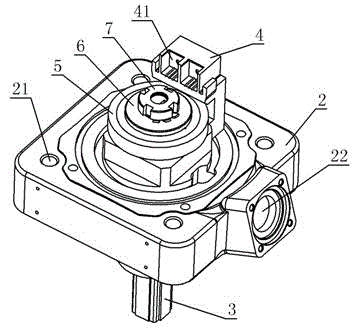

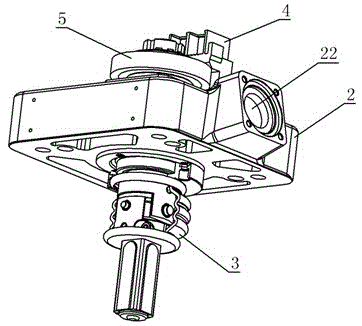

[0034] The structure after removing the cover is as follows figure 2 , image 3 , Figure 4 and Figure 5 As shown, a plurality of fixing holes 21 are set on the device base 2, and the fixing holes 21 are used to fix the device base 2 on the parts outside the rotating shaft of the rail transit locomotive. The side wall of the device base 2 is provided with a wiring channel 22, and the wiring channel 22 The inner space of the connector seat 2 and the cover body 1 is used for laying power lines, signal lines, etc. inside the channel, and the outer interface of the wiring channel 22 can fix the cable connector of the sensor and the like. A circular hole is provided at the cen...

Embodiment 2

[0046] The structure and connection relationship of the cover body, device seat, shafting assembly, magnetic code disc, pressure plate, nut and stop washer of the sensor in this embodiment are the same as in the first embodiment, and the structure of the circuit module 4 is the same as that in the first embodiment The same, the difference is that two circuit modules 4 are fixed on the device base 2, such as Figure 10 shown. The magnetic sensitive elements 42 of the two circuit modules 4 are located on the side of the magnetic code disk 5 . Setting two circuit modules 4 can achieve the purpose of redundant design, and the speed signals detected by the two circuit modules 4 can be sent to the rail transit monitoring system, braking system, etc. to realize multi-channel speed signal output.

Embodiment 3

[0048] The structure and connection relationship of the cover body, device seat, shafting assembly, magnetic code disc, pressure plate, nut and stop washer of the sensor in this embodiment are the same as in the first embodiment, and the structure of the circuit module 4 is the same as that in the first embodiment The same, the difference is that three circuit modules 4 are fixed on the device base 2, such as Figure 11 shown. The magnetic sensitive elements 42 of the three circuit modules 4 are all located on the side of the magnetic code disk 5 . The three circuit modules 4 can also realize redundant design and multiple outputs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com