Optical isolation method and device

An optical isolation and optical wedge technology, applied in the field of optical isolation, can solve the problems of limited power tolerance of optical isolation devices, high material cost, large device package size, etc., achieve optimal reflected light blocking performance, achieve separation, and reduce packaging. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

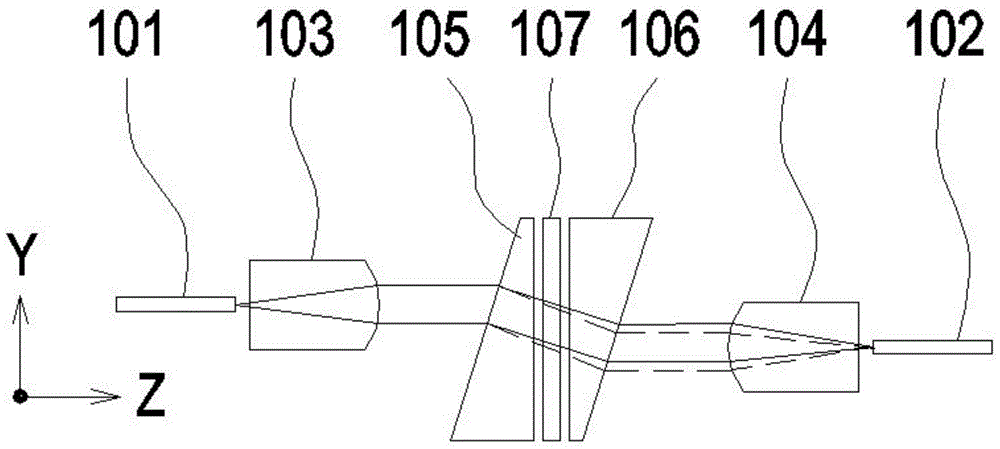

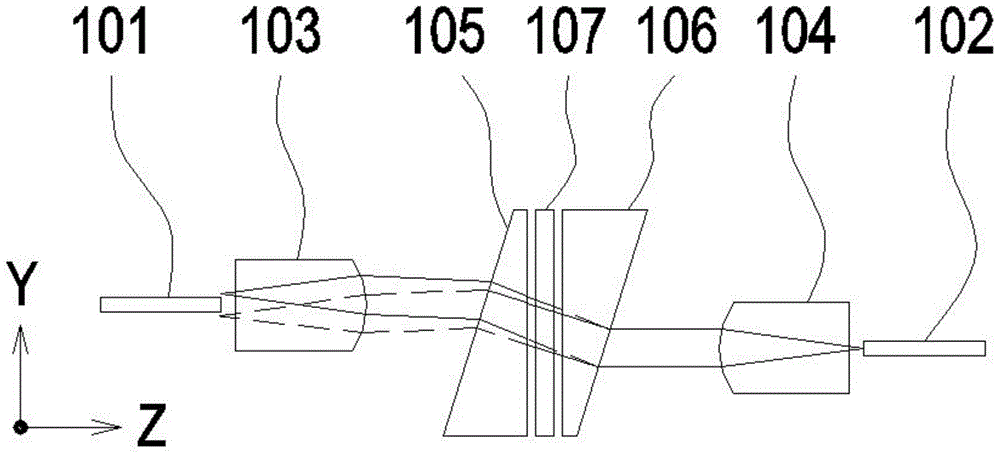

[0034] The invention discloses an optical isolation method, which separates the forward light into two polarized light components, so that a distance is generated in space and an included angle is formed in the propagation direction; After the irreversible light polarization state is rotated, the two polarized light components are combined and output according to the opposite process of separation; the reversed light is separated into two polarized light components, so that a distance is generated in space and the propagation direction forms an included angle; reversed The two polarized light components of the light will deviate from the forward light path after the irreversible light polarization state rotation at the spatial intersection point; set a reverse diaphragm at the place where the forward and reverse light paths do not overlap, pass the forward light and block the reverse direction Light, to achieve the purpose of optical isolation.

[0035] Polarization splitter ...

Embodiment 2

[0051] The difference between the optical isolation device disclosed in this embodiment and the optical isolation device disclosed in Embodiment 1 is that the structure of the polarization beam splitting device is different. The polarization beam splitting device disclosed in this embodiment will be described in detail below, and the optical isolation device The same parts as those in Example 1 will not be described in detail.

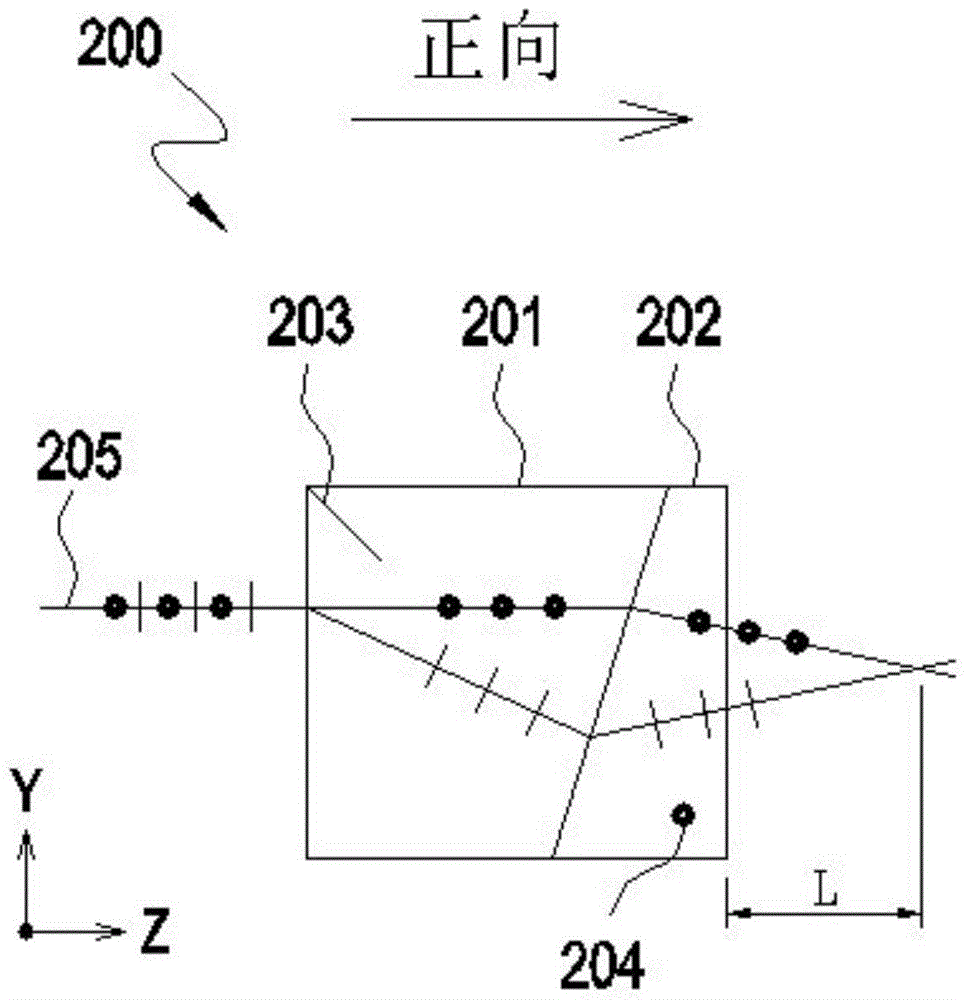

[0052] Polarization splitting device 300 such as Figure 3A and Figure 3BAs shown, it consists of a birefringent parallel displacement crystal 301 and a non-birefringent roof prism 302. The optical axis 303 of the parallel displacement crystal 301 forms an included angle of 45 degrees with the Y axis, and its thickness depends on the position L of the crossing point of the required beams. choose. When a beam of incident light 304 with a random polarization state is perpendicularly incident on the parallel displacement crystal 301 along the positive ...

Embodiment 3

[0055] The difference between the optical isolation device disclosed in this embodiment and the optical isolation device disclosed in Embodiment 1 is that the structure of the polarization beam splitting device is different. The polarization beam splitting device disclosed in this embodiment will be described in detail below, and the optical isolation device The same parts as those in Example 1 will not be described in detail.

[0056] Polarization splitting device 400 such as Figure 4A and Figure 4B As shown, it consists of a birefringent parallel displacement crystal 401 and a non-birefringent optical wedge 402. The optical axis 403 of the parallel displacement crystal 401 forms an included angle of 45 degrees with the Y axis, and its thickness depends on the position L of the crossing point of the required beams. choose. When a beam of incident light 404 with a random polarization state is vertically incident on the parallel displacement crystal 401 along the positive d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com