Manufacturing process of tea

A production process and process technology, which is applied in the field of production process of cold beauty tea, can solve the problems such as no relevant reports, and achieve the effect of strengthening health preservation effect and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

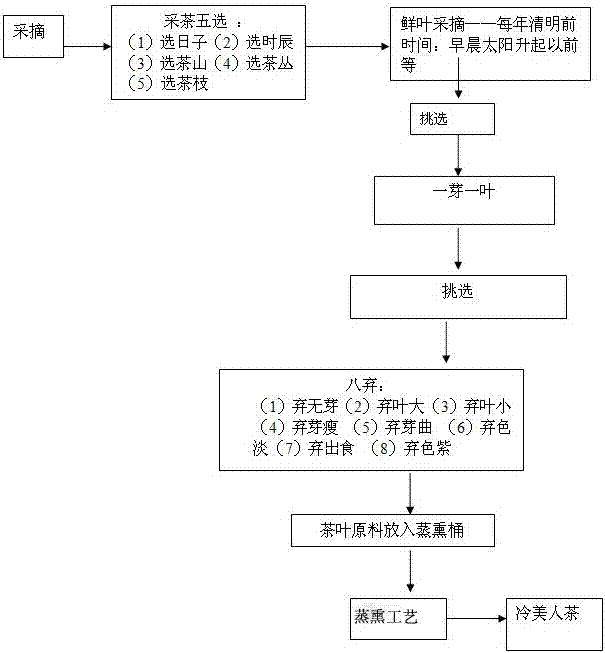

[0054] according to figure 1 As shown, Lengmeiren tea has three steps: picking, selection, and steaming. Among them, picking must follow the five-selection principle, selection must follow the eight-discarding principle, and the steaming process is divided into 18 processes.

[0055] Picking is to pick one bud and one leaf of the tea leaves according to the original five principles of tea picking; the five selection principles of tea picking in the present invention must be followed; the five selection principles are to choose the day, choose the hour, choose the tea mountain, choose the tea cluster, and choose the tea branch . (1) Choose the day: you must pick tea before Qingming every year. After Qingming, the tea will be old and affect the taste; (2) Choose the time: you must get up at around 4 o'clock in the morning to go up the mountain, and pick the tea before the sun rises in the morning. 1. Dewy tea leaves, after the sun rises, the fog in the tea mountain dissipates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com