System and method for preventing raw coal oxidation and spontaneous combustion by pumping low-temperature furnace smoke inerting spherical coal bunker

A low-temperature furnace and spherical technology, applied in medical science, dental prosthetics, fire rescue, etc., can solve problems such as oxidation and spontaneous combustion of stored coal, heat loss of raw coal, and impact on the economical use of stored coal, so as to reduce the consumption and save energy. The effect of desulfurization water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

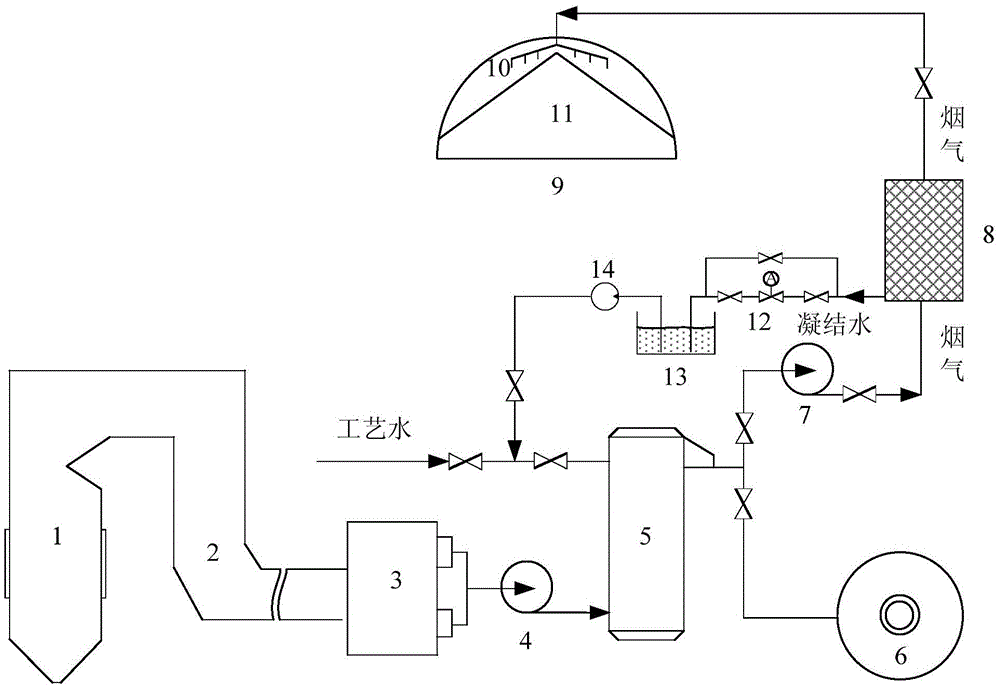

[0020] see figure 1 , the present invention draws low-temperature furnace smoke inertization spherical coal bunker anti-raw coal oxidation spontaneous combustion system, including tail flue heat exchanger 2, dust collector 3, induced draft fan 4, desulfurization tower 5, chimney 6, low-temperature furnace smoke fan 7, smoke Gas preprocessor 8 , flue gas nozzle 10 , automatic trap 12 , condensate pool 13 and condensate pump 14 .

[0021] Among them, the furnace smoke outlet of the boiler 1 is connected to the inlet of the tail flue heat exchanger 2, the outlet of the tail flue heat exchanger 2 is connected to the inlet of the dust collector 3, the outlet of the dust collector 3 is connected to the inlet of the induced draft fan 4, and the induced draft fan 4 The outlet of the desulfurization tower 5 is connected to the furnace smoke inlet of the desulfurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com