Die-casting machine asynchronous servo energy-saving control method and system

An energy-saving control system and energy-saving control technology are applied in the field of energy-saving control of die-casting machines, which can solve the problems of increasing equipment maintenance costs, insufficient power saving, equipment procurement costs, and complicated installation, so as to eliminate light-load no-load operation and eliminate high-voltage shut-off. phenomenon, the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

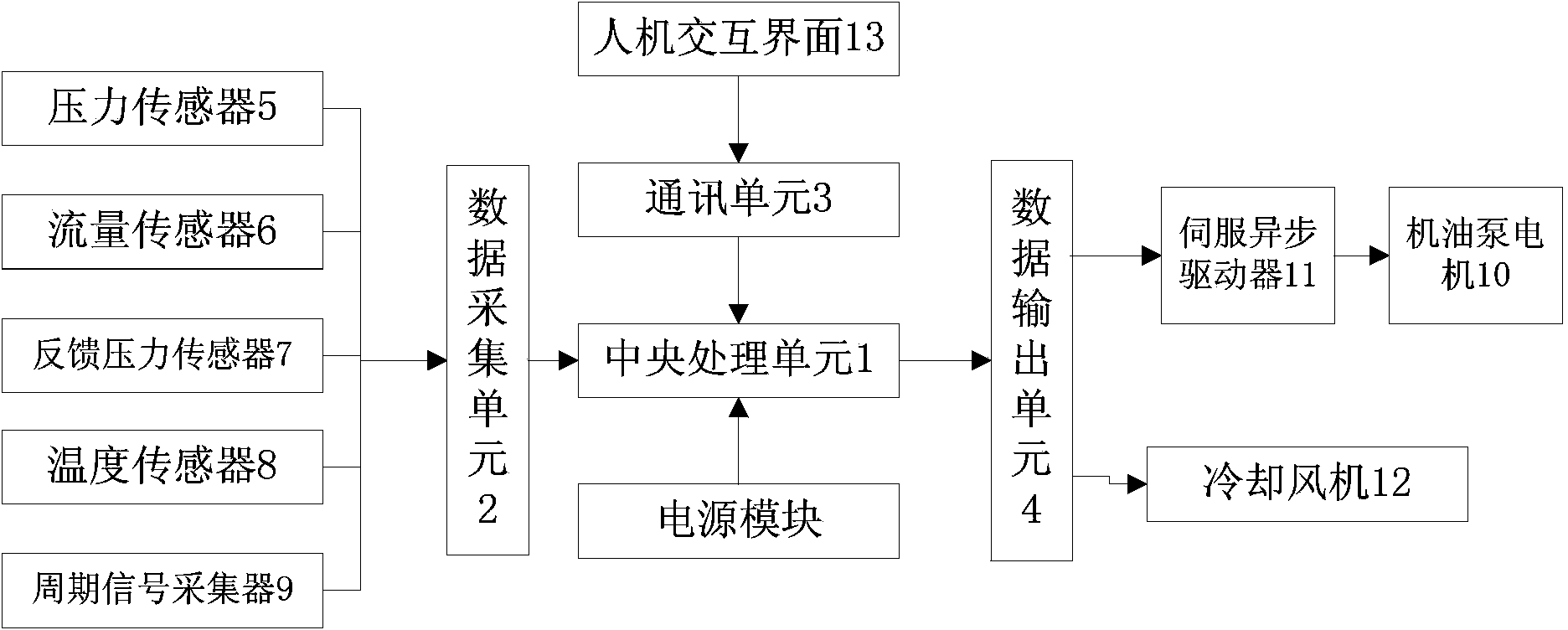

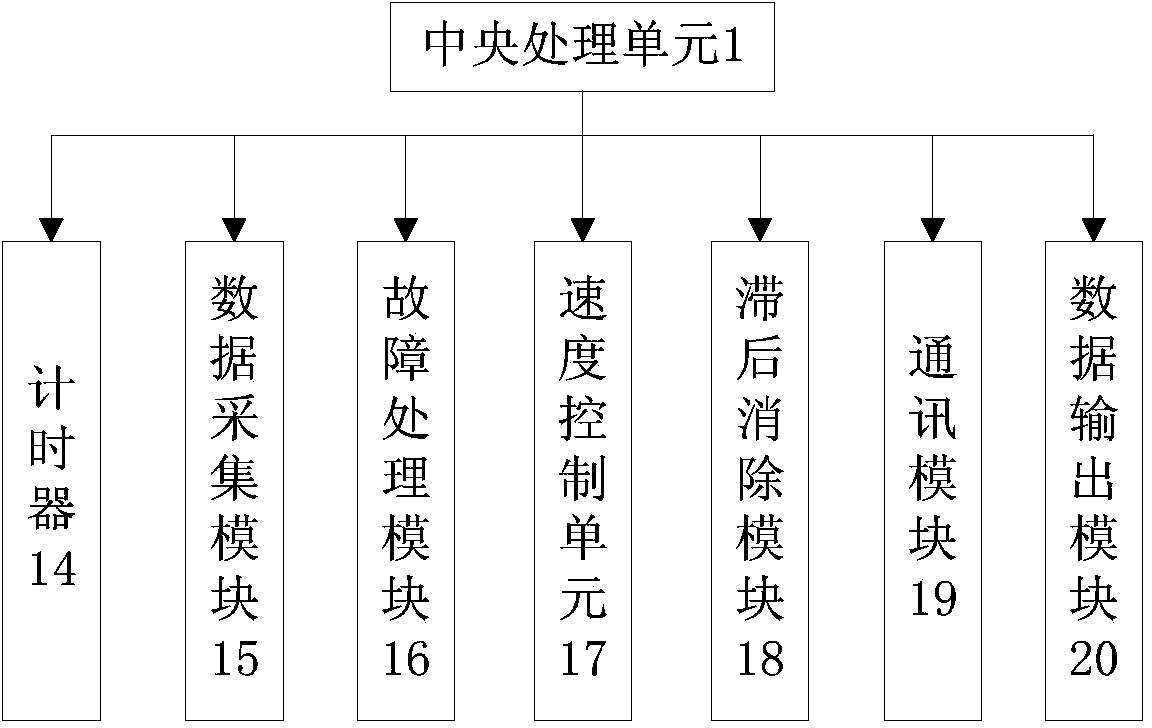

[0048] Such as figure 1 As shown, it is a functional block diagram of an embodiment of an asynchronous servo energy-saving control system for a die-casting machine in the present invention. The asynchronous servo energy-saving control system of the die-casting machine in this embodiment includes a central processing unit 1 and a data acquisition unit 2 , a communication unit 3 , a data output unit 4 , and a power supply module all electrically connected to the central processing unit 1 . The data acquisition unit of this embodiment includes a pressure sensor 5 for collecting the pressure signal of the proportional valve of the die-casting machine, a flow sensor 6 for collecting the flow signal of the proportional valve of the die-casting machine, a feedback pressure sensor 7 for collecting the feedback pressure signal of the oil pump, and Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com