Waterproof And Breathable Sock And Method Of Manufacturing The Same

A waterproof and breathable, waterproof and breathable layer technology, applied in socks, pantyhose, chemical instruments and methods, etc., can solve the problem of lack of waterproof and breathable functions, and achieve the effect of improving the tightness and maintaining a dry state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to understand the technical characteristics and practical effects of the present invention in detail, and to realize them according to the contents of the specification, the preferred embodiment shown in the drawings will be described in detail as follows:

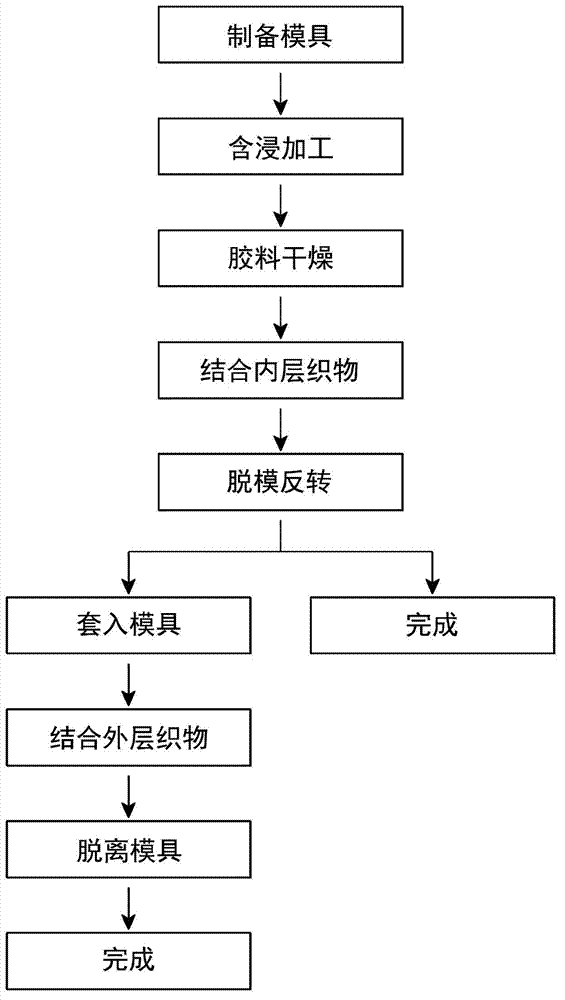

[0041] Please refer to figure 1 shown, which includes:

[0042] Mold preparation: the mold is foot-shaped, and molds of different sizes can be customized according to different users, and the surface of the mold can have texture;

[0043] Impregnation processing: Soak the mold in the rubber material to make the rubber material adhere to the surface of the mold. The rubber material can be PU (polyurethane), NR (natural rubber), NBR (nitrile rubber), Neoprene (chloroprene rubber), PVA (polyvinyl alcohol), Viton (fluorine rubber) or PVC (polyvinyl chloride);

[0044] Among them, PU is waterproof and breathable, NR is wear-resistant, acid and alkali resistant, NBR is wear-resistant and cut-resistant, Neopren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com