Floating type rotary hot gold stamping method and device

A round-pressing and floating-type technology, which is applied in gold powder printing, printing, rotary printing machines, etc., can solve problems that affect printing effects and printing quality, foil deviation, bronzing misprints, etc., to improve printing effects and printing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

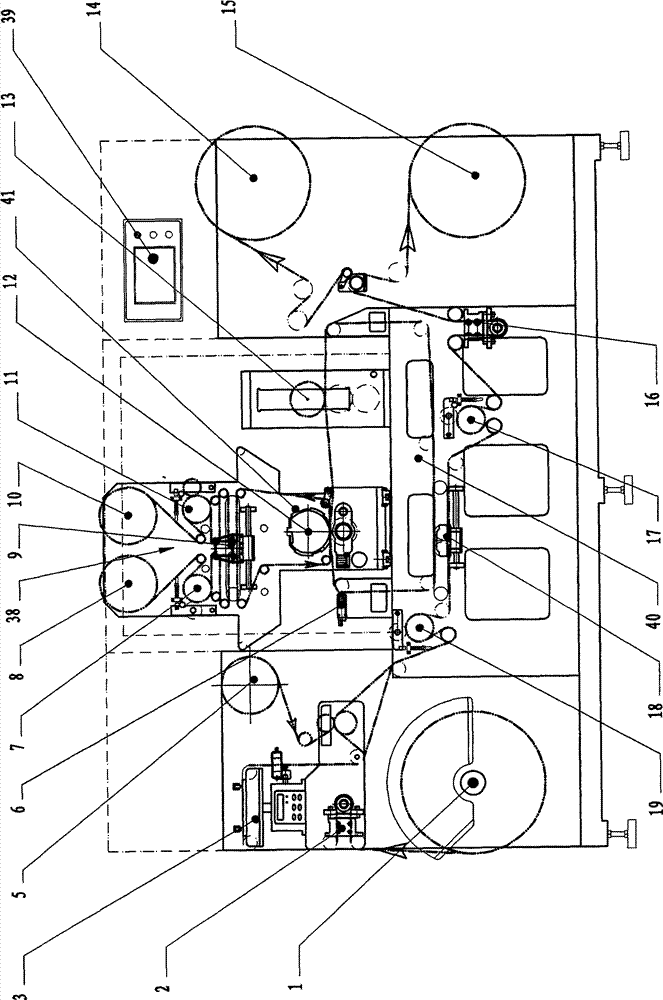

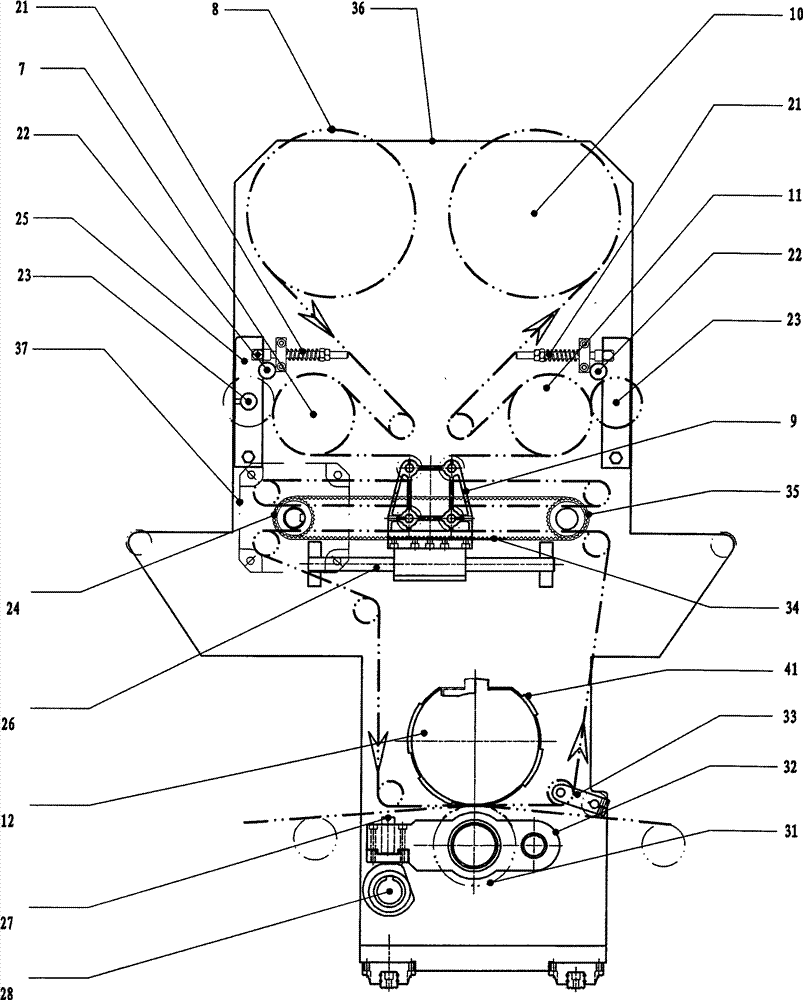

[0010] refer to figure 1 , figure 2 It can be seen that the present invention is applied to the floating round hot stamping device on the intermittent round hot stamping die-cutting machine, including the archway 36, the hot stamping foil mechanism 8, the hot stamping waste collection mechanism 10, the hot stamping roller 12 (the inside is oil heating method), bottom roller 31 (and front bronzing traction roller 7, rear bronzing traction roller 11), on the archway 36, and on the bronzing foil release mechanism 8 (or bronzing waste collection mechanism 10) and bronzing roller 12 (or bottom Roller 31) station place is equipped with guide rail slide assembly 26, and this guide rail slide assembly 26 links to each other with power source 37 by intermediate transmission assembly, and bronzing floating roller 9 is housed on this guide rail slide assembly 26.

[0011] Wherein, the intermediate transmission assembly is installed on the archway 36, which includes a synchronous belt 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com