All-solid waste black glass ceramic and preparation method and application thereof

A technology of black glass and ceramics, applied in the field of all-solid waste black glass ceramics and its preparation, can solve the problems of low comprehensive utilization rate of solid waste and environmental pollution, achieve bright and black color, solve environmental pollution, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

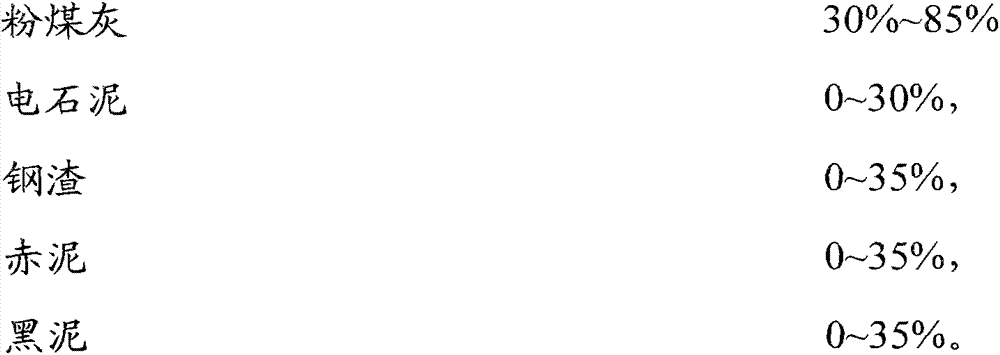

Method used

Image

Examples

Embodiment 1

[0017] (1) Evenly mix 30% of fly ash, 15% of calcium carbide mud, 15% of steel slag, 15% of red mud and 25% of black mud, and heat in a high-temperature furnace at 1400°C to 1600°C for 1 After ~4h, melt to obtain the glass body, adjust the temperature at 550°C to 650°C for 30min to 1h, and cool down with the furnace to obtain the basic glass;

[0018] (2) Put the basic glass obtained in step (1) into a heat treatment furnace after molding, heat it at 800° C. to 1050° C. for 2 hours for crystallization heat treatment, and then cool it to obtain the all-solid waste black glass ceramics 1 .

Embodiment 2

[0020] (1) Evenly mix 85% fly ash, 10% steel slag and 5% black mud, place in a high-temperature furnace and heat at 1400°C to 1600°C for 1 to 4 hours, then melt to obtain a glass body, and adjust the temperature to 550°C ~650°C annealing for 30min~1h, then cooling with the furnace to obtain basic glass;

[0021] (2) Put the basic glass obtained in step (1) into a heat treatment furnace after molding, heat it at 800° C. to 1050° C. for 1 hour to carry out crystallization heat treatment, and then cool to obtain all-solid waste black glass ceramics 2 .

Embodiment 3

[0023] (1) Evenly mix 60% fly ash, 15% calcium carbide mud, 5% steel slag and 20% red mud, place in a high-temperature furnace and heat at 1400°C to 1600°C for 1 to 4 hours, then melt to obtain a glass body , adjust the temperature at 550°C to 650°C for 30min to 1h, and then cool with the furnace to obtain the basic glass;

[0024] (2) Put the basic glass obtained in step (1) into a heat treatment furnace after molding, heat it at 800° C. to 1050° C. for 1 to 2 hours for crystallization heat treatment, and then cool to obtain all-solid waste black glass ceramics 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com