A kind of tourmaline/glass composite material and preparation method thereof

A composite material and tourmaline technology, applied in the field of tourmaline/glass composite materials and their preparation, can solve problems such as poor functionality and durability of effects, demanding sintering conditions, and easily polluted ceramic surfaces, and achieve production energy consumption. Low cost, good for environmental protection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of small glass particles:

[0035] (1) Ingredients: weighed according to the weight percentage of the glass: Bi 2 o 3 40%; B 2 o 3 20%;Al 2 o 3 7%; ZnO20%; CaO10%; SiO 2 3%;

[0036] (2) Mixing: Mix the components weighed according to the weight percentage by ball milling, and the mixing time is 10 minutes;

[0037] (3) Melting: Put the above materials in a high-temperature furnace with a melting temperature of 600°C and a holding time of 2 hours to obtain molten glass;

[0038] (4) Cooling: Quench the molten glass with water and then dry it to obtain small glass particles for use.

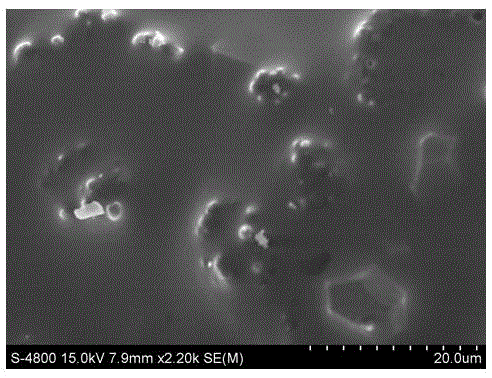

[0039] 2) Preparation of tourmaline / glass composite material: the composition of the weight percentage formula of the composite material is 5% ferrite tourmaline and 95% glass; the tourmaline and glass are mixed evenly by ball milling, and the mixing time is 10 minutes; the uniformly mixed tourmaline powder / Glass powder composite powder is placed in a high-temperatu...

Embodiment 2

[0042] 1) Preparation of small glass particles:

[0043] (1) Ingredients: weighed according to the weight percentage of glass: Bi 2 o 3 50%; B 2 o 3 15%;Al 2 o 3 4%; ZnO12%; CaO6%; SiO 2 13%;

[0044] (2) Mixing: Mix the raw materials weighed according to the weight ratio by ball milling, and the mixing time is 15 minutes;

[0045] (3) Melting: Put the above materials in a high-temperature furnace with a melting temperature of 700°C and a holding time of 2 hours to obtain molten glass;

[0046] (4) Cooling: Quench the molten glass with water and then dry it to obtain small glass particles for use.

[0047] 2) Preparation of tourmaline / glass composite material: the composition of the formula is 10% ferrite tourmaline and 90% glass; the tourmaline and glass are mixed uniformly by ball milling, and the mixing time is 15 minutes; the uniformly mixed tourmaline powder / glass powder composite powder The body was placed in a high-temperature furnace, raised to 200°C at a heat...

Embodiment 3

[0050] 1) Preparation of small glass particles:

[0051] (1) Ingredients: weighed according to the weight percentage of the glass: Bi 2 o 3 65%; B 2 o 3 10%;Al 2 o 3 3%; ZnO10%; CaO5%; SiO 2 7%;

[0052] (2) Mixing: Mix the raw materials weighed according to the weight ratio by ball milling, and the mixing time is 10 minutes;

[0053] (3) Melting: Put the above materials in a high-temperature furnace with a melting temperature of 900°C and a holding time of 2 hours to obtain molten glass;

[0054] (4) Cooling: Quench the molten glass with water and then dry it to obtain small glass particles for use.

[0055] 2) Preparation of tourmaline / glass composite material: its weight percentage formula composition is 15% ferrite tourmaline and 85% glass; the tourmaline and glass are mixed evenly by ball milling, and the mixing time is 13 minutes; the uniformly mixed tourmaline powder / glass The powder composite powder is placed in a high-temperature furnace, raised to 400°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

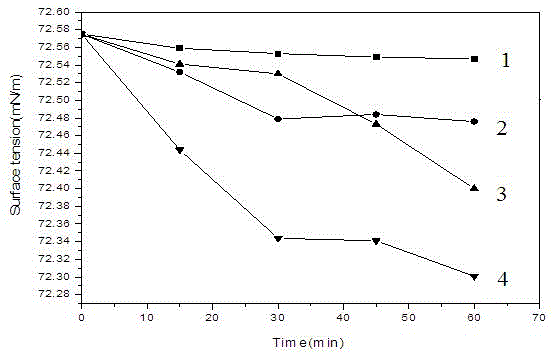

| particle size | aaaaa | aaaaa |

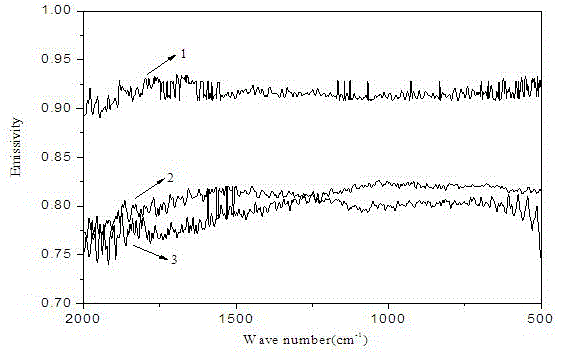

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com