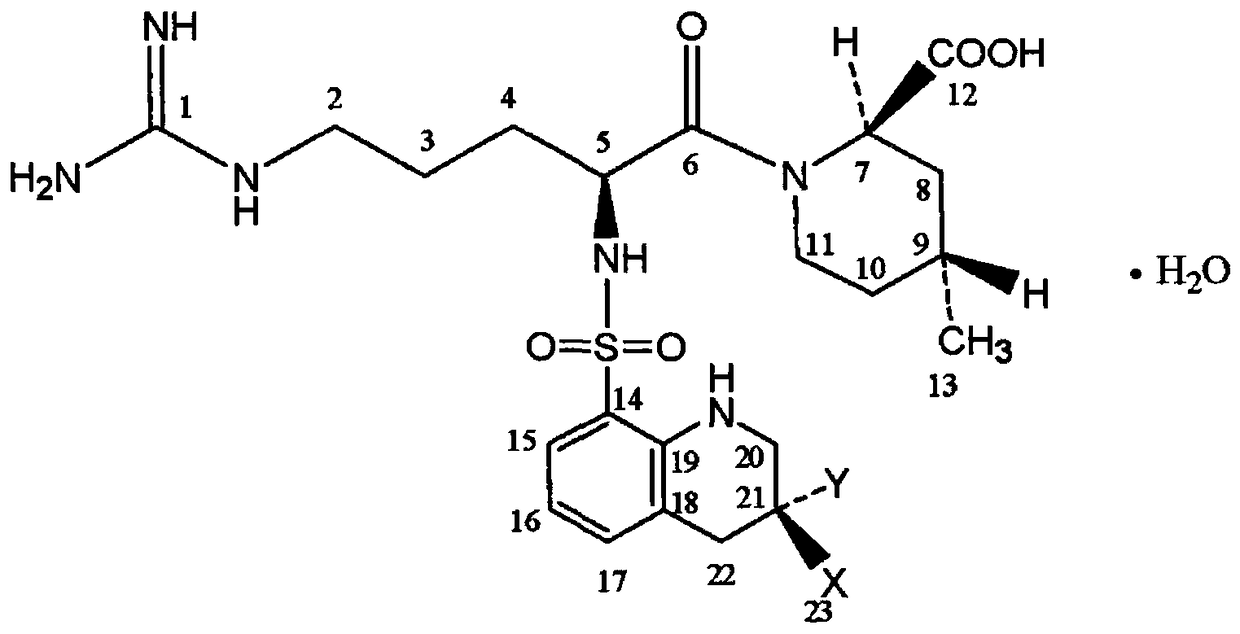

A kind of preparation method of argatroban monohydrate

A technology for argatroban and monohydrate, which is applied in the field of preparation of argatroban monohydrate, and can solve the problems of large changes in the ratio of the 21-position R/S isomer, cumbersome operation, and many solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 20L of ethanol / purified water mixed solvent (ethanol accounted for 97% by volume) to 1019g of crude argatroban, and heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 6 hours. Obtained 704 g of white powder.

[0023] Add 14L of ethanol / purified water mixed solvent (volume ratio of ethanol is 97%), heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 12 hours. 600.5 g of white powder was obtained.

[0024] Add 7.2L of ethanol / purified water (volume ratio of ethanol is 25%), stir and heat to reflux, add 60g of activated carbon and continue stirring for 0.5h. After filtering, the filtrate was naturally cooled to room temperature with stirring, ...

Embodiment 2

[0026] Add 2L of ethanol / purified water mixed solvent (97% ethanol by volume) to 100g of crude argatroban, and heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 8 hours. 71.2 g of white powder were obtained.

[0027] Add 1.4L ethanol / purified water mixed solvent (ethanol accounted for 97% by volume), heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 14 hours. 62 g of white powder were obtained.

[0028] Add 740mL of ethanol / purified water (volume ratio of ethanol is 25%), stir and heat to reflux, add 6.2g of activated carbon and continue stirring for 0.5h. After filtering, the filtrate was naturally cooled to room temperature with stirring, and the...

Embodiment 3

[0030] Add 1.2 L of ethanol / purified water mixed solvent (ethanol accounted for 97% by volume) to 60 g of crude argatroban, and heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 7 hours. 42.6 g of white powder were obtained.

[0031] Add 850mL ethanol / purified water mixed solvent (ethanol accounted for 97% by volume), heat to reflux to dissolve. After complete dissolution, cool down to room temperature, then cool down to 0-5°C and stir for crystallization for 3 hours. Filter with suction and dry under normal pressure at 50°C for 12 hours. 38 g of white powder were obtained.

[0032] Add 460mL of ethanol / purified water (volume ratio of ethanol is 25%), stir and heat to reflux, add 3.5g of activated carbon and continue stirring for 0.5h. After filtering, the filtrate was naturally cooled to room temperature with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com