Double-solution type preparation method for high-heat-resistance high-wear-resistance polyurethane

A technology of polyurethane and its production method, which is applied in the field of polyurethane manufacturing, can solve the problem of peeling, abrasion and flexibility that cannot meet the requirements of the high-end market, the melting point cannot exceed 170°C, and the urethane bond It can save the cost of heating equipment, solve air and water pollution, and solve solvent pollution and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

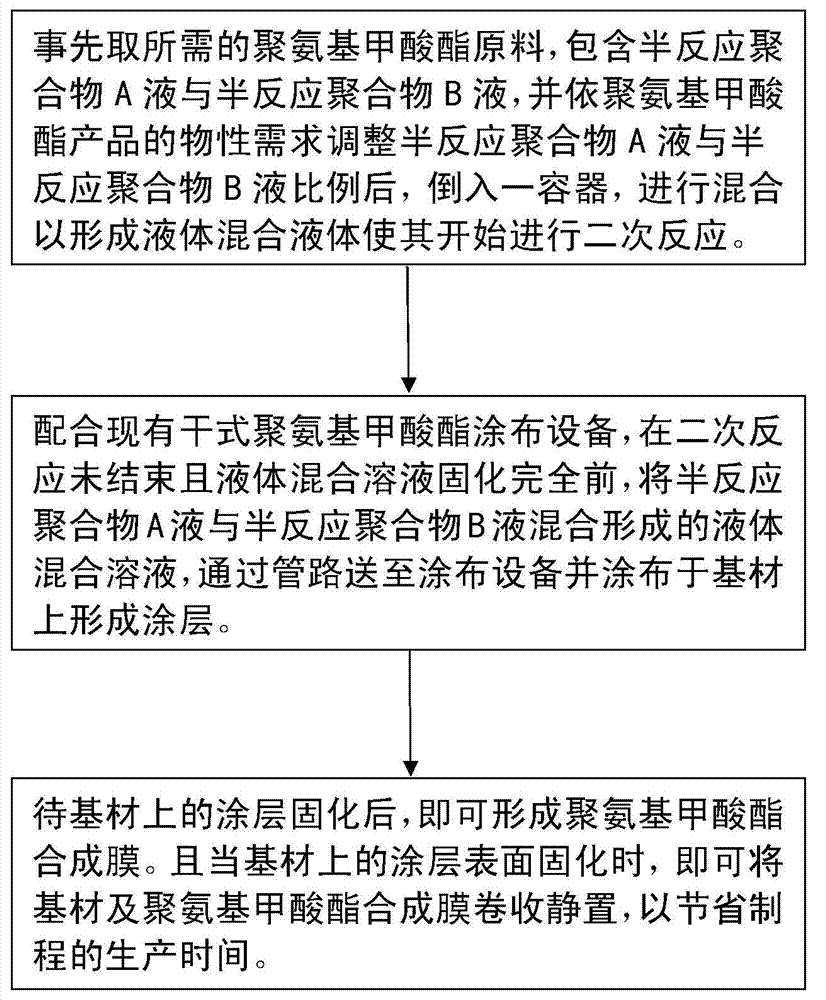

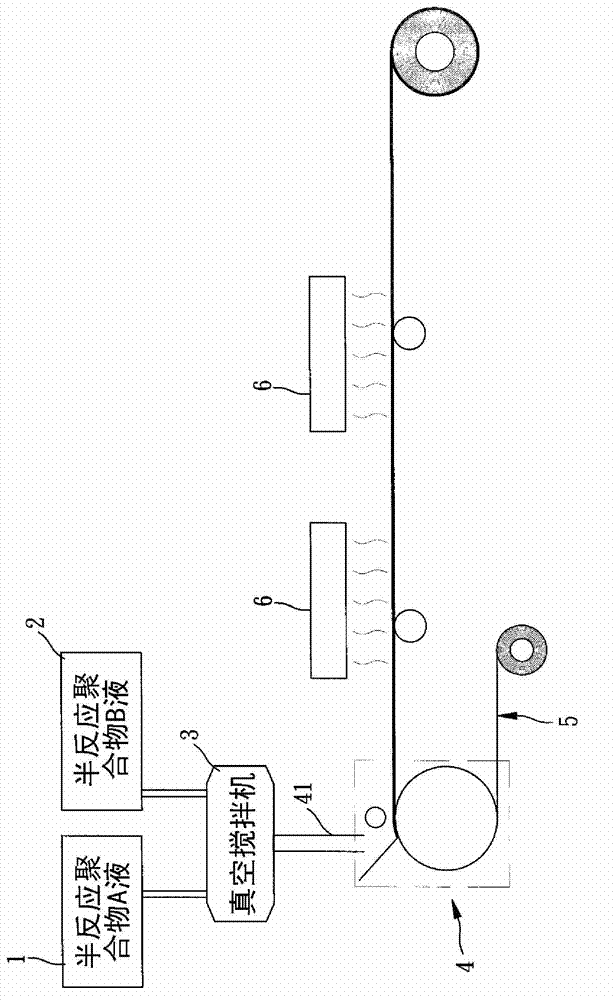

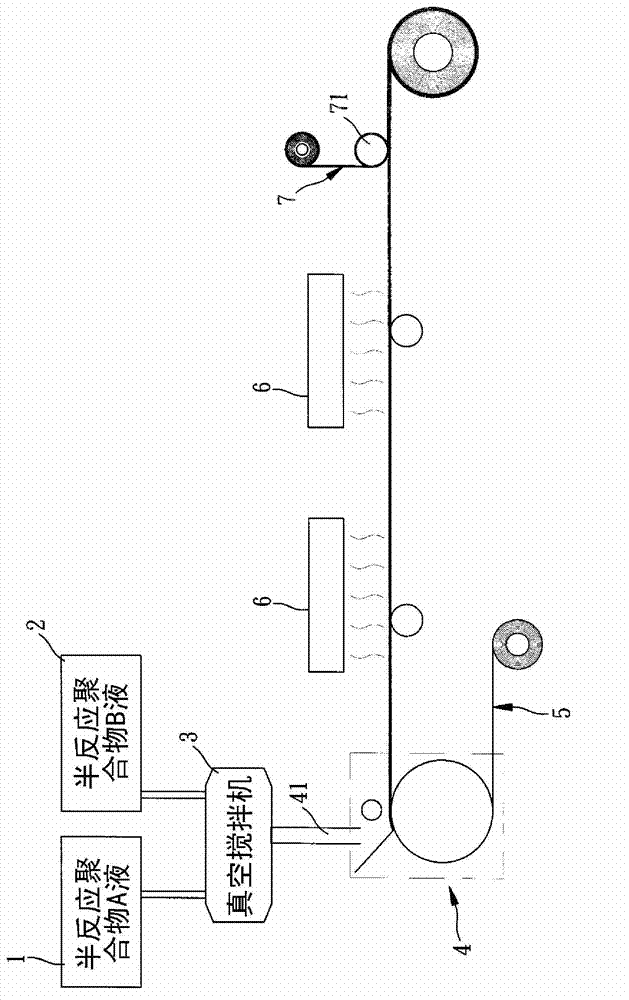

[0046] see figure 1 , figure 2 shown, where figure 1 It is a flow chart showing the steps of the two-component method for producing high heat-resistant and high-abrasion polyurethane of the present invention, figure 2 It is a schematic diagram illustrating a two-component method for producing high heat-resistant and high-abrasion polyurethane according to an embodiment of the present invention. In the two-liquid type production method of the present invention, the half-reacted polymer A liquid 1 and the half-reacted polymer B liquid 2 are first produced through prepolymerization, and then the two liquids are mixed to form a liquid mixed solution for secondary reaction. There is about 30 minutes of operating time before the liquid mixed solution is solidified. During this time, the liquid mixed solution is still in a liquid state, and it is convenient to apply the liquid mixed solution to the substrate by a dry PU coating machine.

[0047] 1: Semi-reactive polymer liquid A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com