Method for recycling acetic acid device byproduct steam

A technology of by-product steam and acetic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of large displacement of by-product steam, energy waste, environmental pollution, etc., and achieve the effect of solving energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

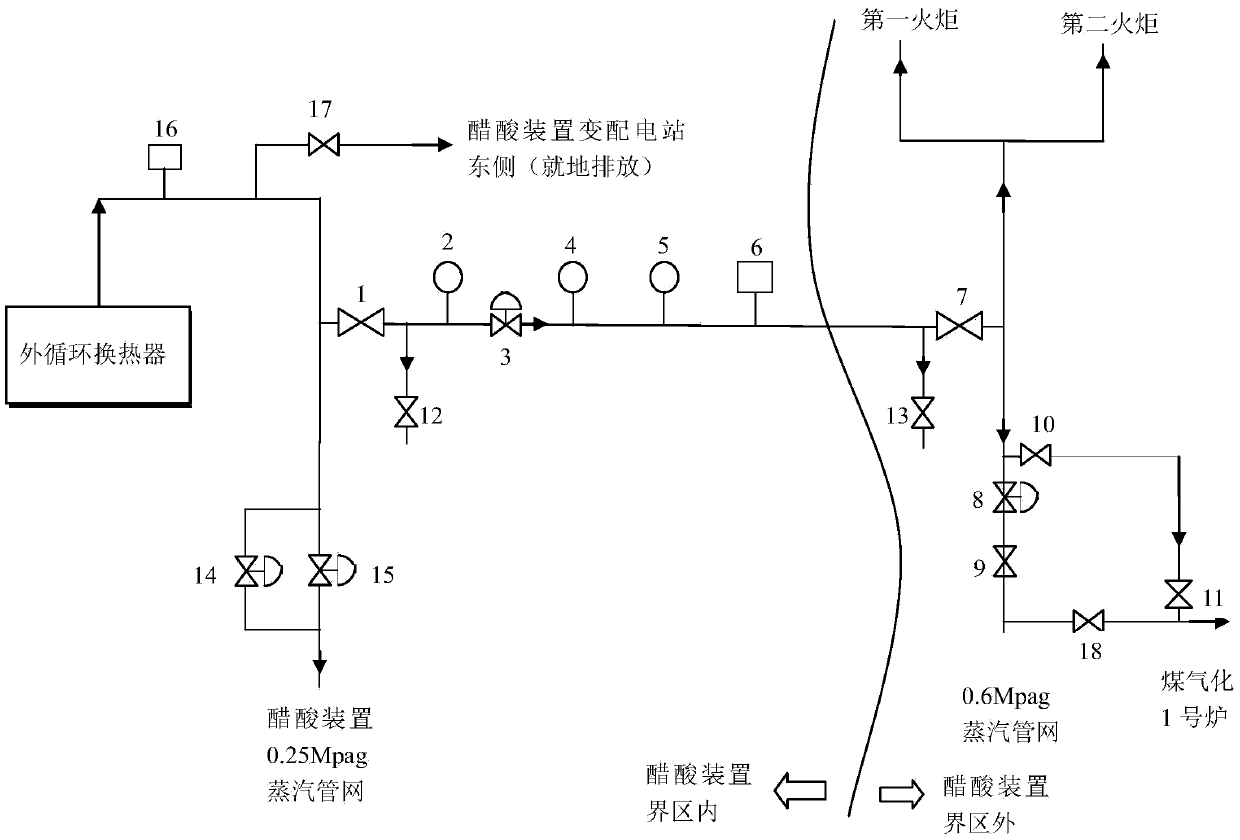

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown in the system for recovering the by-product steam of the acetic acid plant, a first cut-off valve 1 is provided on the pipeline connecting the external heat exchanger and the 0.25Mpag steam pipe network of the acetic acid plant, and a second cut-off valve is provided on the pipeline of the 0.6Mpag steam pipe network. Valve 7; the first shut-off valve 1 and the second shut-off valve 7 are connected through pipelines and equipped with corresponding instrument accessories: first pressure transmitter 2, first regulating valve 3, thermometer 4, second pressure transmitter 5 and the first flow meter 6; in order to prevent the water storage in the newly connected pipeline from affecting the process stability, the sixth shut-off valve 12 and the seventh shut-off valve 13 are connected; the pipeline in the 0.6Mpag steam pipeline networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com