Conductive adhesive composition and conductive adhesive membrane

A technology of conductive adhesives and compositions, applied in the direction of conductive adhesives, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve problems such as reducing instrument reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

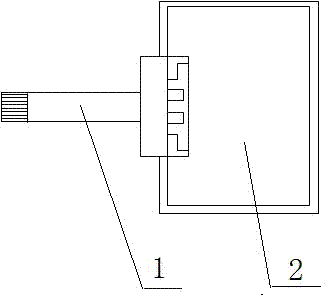

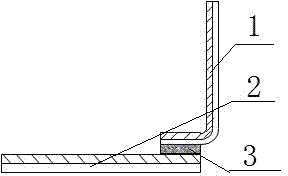

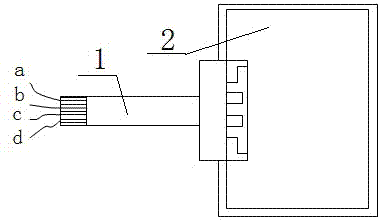

Image

Examples

Embodiment 1

[0044] The present embodiment provides a conductive adhesive composition, including the following components: in parts by weight, polyamide elastomer: TPAE-32 (produced by T&K TOKA Co., Ltd.) 15 parts by weight; acrylic elastomer: SG-708- 6T (carboxyl group-containing acrylic resin, manufactured by NagaseChemteX Corporation) 15 parts by weight; epoxy resin: Epikote 828 (manufactured by Japan Epoxy Resins Co., Ltd., number of epoxy groups per molecule: 2) 50 parts by weight; phenolic resin: CKM -1282 (produced by Japan Showa Polymer Co., Ltd.) 20 parts by weight; accelerator: 2E4MZ (produced by Shikoku Chemicals Co., Ltd., Japan) 0.5 parts by weight; conductive particles: CE-1110 (dendritic, produced by Fukuda Metal Foil Powder Industry Co., Ltd.) 50 Parts by weight; solvent methyl ethyl ketone (MEK) 225 parts by weight.

[0045] The conductive adhesive composition of this embodiment was prepared by kneading for 3 hours by a planetary mixer at room temperature and a rotation sp...

Embodiment 2

[0047] This embodiment provides a conductive adhesive composition, including the following components: in parts by weight, polyamide elastomer: TPAE-32 (produced by T&K TOKA Co., Ltd.) 55 parts by weight; acrylic elastomer: SG-708- 6T (carboxyl-containing acrylic resin, manufactured by NagaseChemteX Corporation) 15 parts by weight; epoxy resin: Epikote 828 (manufactured by Japan Epoxy Resins Co., Ltd., number of epoxy groups per molecule: 2) 30 parts by weight; accelerator: 2E4MZ (Shikoku Kasei Co., Ltd.) 0.4 parts by weight; conductive particles: CE-1110 (dendritic, produced by Fukuda Metal Foil Powder Industry Co., Ltd.) 100 parts by weight; solvent methyl ethyl ketone (MEK) 300 parts by weight.

[0048] The conductive adhesive composition of this embodiment was prepared by kneading for 3 hours by a planetary mixer at room temperature and a rotation speed of 100 rpm.

Embodiment 3

[0050] The present embodiment provides a conductive adhesive composition, including the following components: in parts by weight, polyamide elastomer: TPAE-32 (produced by T&K TOKA Co., Ltd.) 15 parts by weight; acrylic elastomer: SG-708- 6T (carboxyl-containing acrylic resin, manufactured by NagaseChemteX Corporation) 55 parts by weight; phenolic resin: 30 parts by weight of CKM-1282 (manufactured by Japan Showa Polymer Co., Ltd.); accelerator: 2E4MZ (manufactured by Shikoku Chemicals Co., Ltd., Japan) 0.05 parts by weight ; Conductive particles: CE-1110 (dendritic, produced by Fukuda Metal Foil Powder Industry Co., Ltd.) 40 parts by weight; solvent methyl ethyl ketone (MEK) 210 parts by weight.

[0051] The conductive adhesive composition of this embodiment was prepared by kneading for 3 hours by a planetary mixer at room temperature and a rotation speed of 100 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com