Method for extracting Chinese eaglewood essential oil

An extraction method and technology of agarwood essential oil, applied in the directions of essential oil/spice, fat production, etc., can solve problems such as limiting the production efficiency of agarwood essential oil, and achieve the effects of shortening extraction time, reducing extraction time, and improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

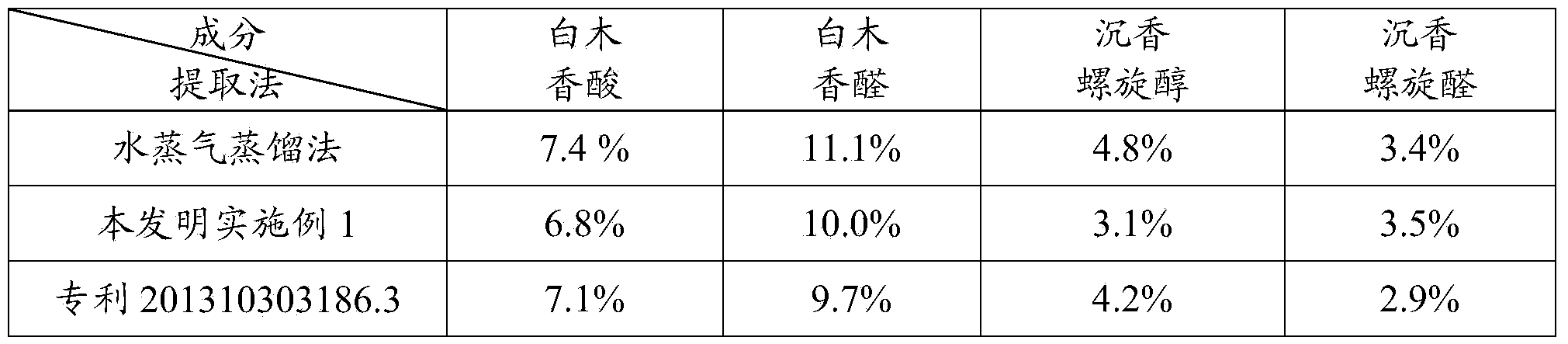

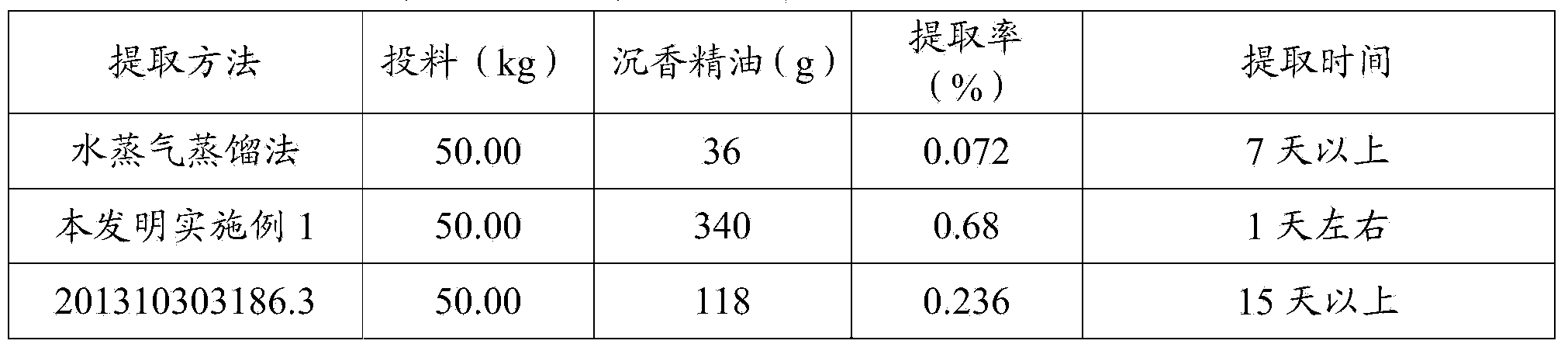

[0028] Embodiment 1: the extraction method of agarwood essential oil of the present invention

[0029] Take 50.0 kg of agarwood raw material (agarwood containing white wood layer) and pulverize it, add purified water of 6 times the weight of the agarwood raw material, stir to form a slurry, and pass the slurry through a colloid mill;

[0030] After the colloid mill is completed, the slurry is ultrasonically treated under the conditions of 2750W and 75min. After the treatment, the pH is adjusted to 5.0 with hydrochloric acid, and the amount of cellulase with a specific activity of 3.0 is added per kilogram of agarwood raw material for cellulase hydrolysis. The hydrolysis temperature is 45 ℃, the hydrolysis time is 210 minutes, and the enzyme inactivation is carried out after the hydrolysis is completed. The enzyme inactivation temperature is above 90 ℃, and the enzyme inactivation time is 5 minutes;

[0031] Suction filtration after enzyme inactivation, the first filtrate of ga...

Embodiment 2

[0032] Embodiment 2: the extraction method of agarwood essential oil of the present invention

[0033] Take 50.0 kg of agarwood raw material (agarwood containing white wood layer) and pulverize it, add purified water twice the weight of the agarwood raw material, stir to form a slurry, and pass the slurry through a colloid mill;

[0034] After the colloid mill is completed, the slurry is ultrasonically treated under the conditions of 500W and 120min. After the treatment, the pH is adjusted to 5.0 with hydrochloric acid, and the amount of cellulase with a specific activity of 0.3 is added per kilogram of agarwood raw material for cellulase hydrolysis. The hydrolysis temperature is 45 ℃, the hydrolysis time is 300 minutes, and the enzyme inactivation is carried out after the hydrolysis is completed. The enzyme inactivation temperature is above 90 ℃, and the enzyme inactivation time is 5 minutes;

[0035] Suction filtration after enzyme inactivation, the first filtrate of gained ...

Embodiment 3

[0036] Embodiment 3: the extraction method of agarwood essential oil of the present invention

[0037] Take 50.0% of the agarwood raw material (agarwood containing white wood layer) and pulverize it, add purified water 10 times the weight of the agarwood raw material, stir to form a slurry, and pass the slurry through a colloid mill;

[0038] After the colloid mill is completed, the slurry is ultrasonically treated under the conditions of 5000W and 30min. After the treatment, the pH is adjusted to 4.5 with hydrochloric acid, and the amount of cellulase with a specific activity of 1.0 is added per kilogram of agarwood raw material for cellulase hydrolysis. The hydrolysis temperature is 47 ℃, the hydrolysis time is 270 minutes, and the enzyme inactivation is carried out after the hydrolysis is completed. The enzyme inactivation temperature is above 90 ℃, and the enzyme inactivation time is 5 minutes;

[0039]Suction filtration after enzyme inactivation, the first filtrate of gai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com