Quenching equipment for completing quenching, isothermal treatment or tempering in same slot by transferring through hanging basket

A technology of quenching equipment and hanging basket, applied in the field of heat treatment equipment, can solve the problems of investment cost, high operating cost, severe corrosion, serious deformation, complex equipment structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

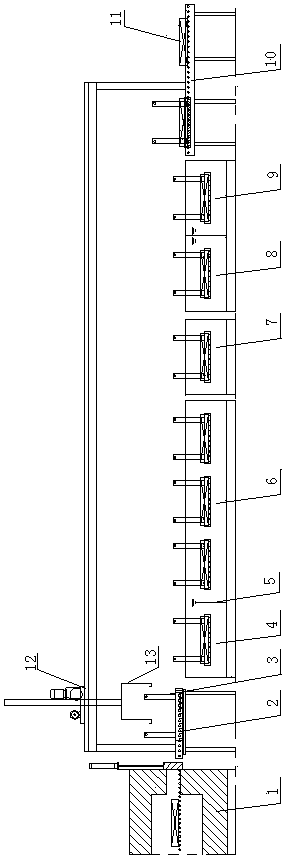

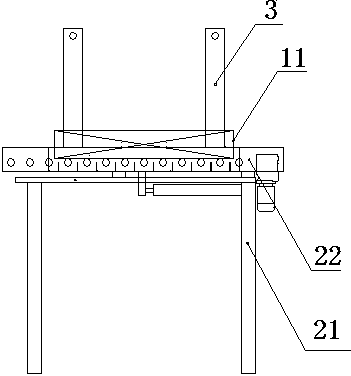

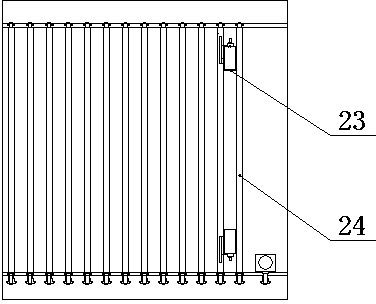

[0034] see figure 1 , the quenching equipment that completes quenching, isothermal or tempering in the same tank with hanging basket transfer described in this embodiment is composed of a heating furnace 1, a discharge table 2, a hanging basket 3, a quenching tank 4, an isothermal tank 6, an air-cooled Tank 7, salt water cleaning tank 8, clean water cleaning tank 9, unloading table 10, transfer manipulator 12, retrieving hook 13, wherein, quenching tank 4, isothermal tank 6, air cooling tank 7, salt water cleaning tank 8, clean water cleaning Groove 9 is arranged sequentially from discharge platform 2 to discharge platform 10, and transfer manipulator 12 is arranged on the top between discharge platform 2 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com