Vacuum continuous separation and recovery device for mixed metals in electronic waste

A technology of electronic waste and mixed metals, which is applied in the field of metal recycling and harmless treatment, can solve the problems of waste electrolyte pollution, high consumption of chemicals, secondary pollution, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

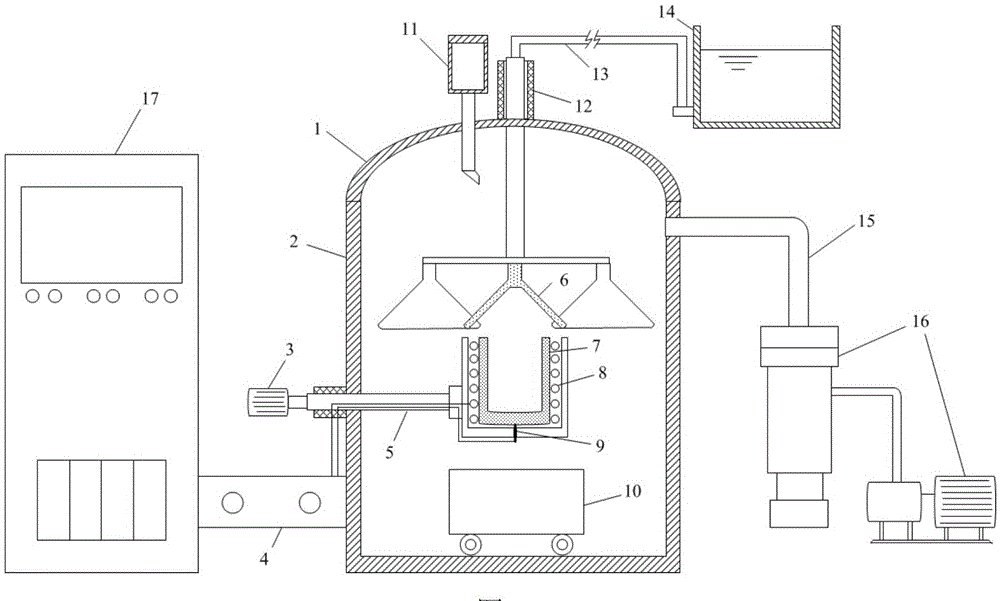

[0028] see figure 1 , figure 1 It is a structural diagram of the vacuum continuous separation and recovery device for electronic waste mixed metals of the present invention. As shown in the figure, a vacuum continuous separation and recovery device for electronic waste mixed metals includes a vacuum furnace body and a material heating device installed in the vacuum furnace body. Device and discharging device 10, continuous feeding device 11, condensation collecting device, electric control system 17, and three sets of pneumatic devices composed of motor 3 and transmission assembly 5 respectively.

[0029] The vacuum furnace body includes a furnace cover 1 and a furnace body 2. The furnace cover 1 is externally connected with a first set of pneumatic devices, which can lift...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap