Heat homogenizing method based on heat conducting graphite film for floor heating

A heat-conducting graphite film and heat method technology, which is applied in the field of building floor heating, can solve the problems of poor soaking effect of the soaking layer and slow heating of the heating space, and achieve the effects of low price, uniform ground temperature and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Since the heat-conducting graphite film based on natural graphite is cheap, the embodiment of the present invention preferably uses the heat-conducting graphite film based on natural graphite. The present invention is not limited to the structure and implementation details described or illustrated below, and other specific embodiments are also possible.

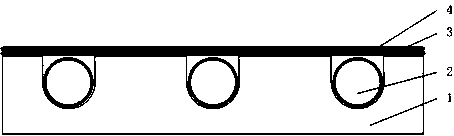

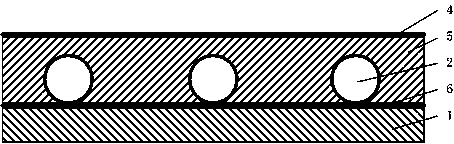

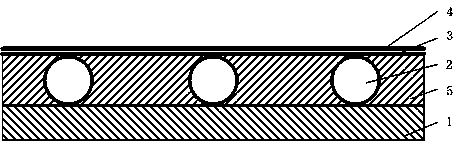

[0025] Such as figure 2 As shown, in Embodiment 1 of the present invention, the thermal insulation board 1 with prefabricated grooves is used as the filling material to fill up the gaps between the heat media 2 . It first places the heat medium 2 in the groove of the prefabricated grooved insulation board 1 . The thermal insulation board 1 of prefabricated groove can use extruded plastic plate as thermal insulation material, and opens the groove required for placing heat medium 2 above, forms the thermal insulation board 1 with prefabricated groove. The depth of the prefabricated groove must be equal to or exceed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com