Combined heat exchange system

A heat exchange system and combined technology, applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problem of large area, easy cracking safety accident, large pressure drop loss of heat exchanger, etc. problems, to achieve the effect of small pressure drop loss, less expansion and cracking, small flow resistance and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

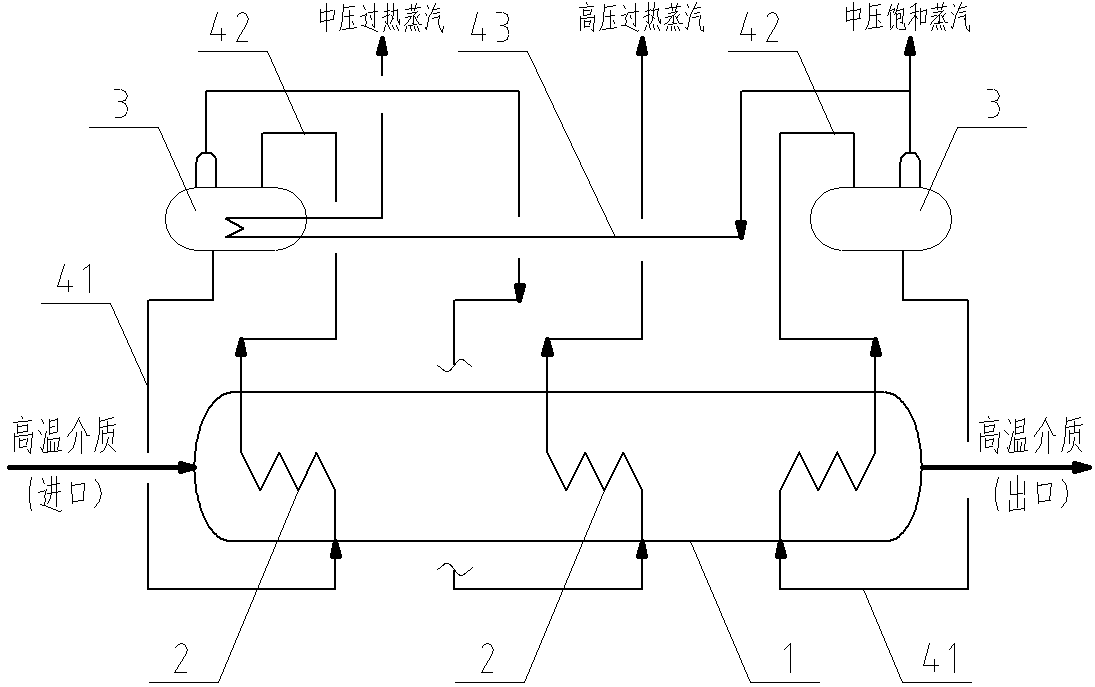

[0026] The system flow of Embodiment 1 of the present invention is as figure 1 As shown, the combined heat exchange system of this embodiment includes a shell 1 with a high-temperature medium inlet at one end and a high-temperature medium outlet at the other end. The inner wall of the shell 1 is provided with a heat insulating material, and the shell 1 is provided with a There are three heat exchange tube bundles 2 distributed sequentially in the flow direction of the high-temperature medium. There are two steam drums 3 connected to the heat exchange tube bundles 2 through pipes outside the shell 1. The temperature of the first steam drum is higher than that of the second steam drum. temperature, a downcomer 41 is provided between the first steam drum and the inlet of the first heat exchange tube bank, and a riser 42 is provided between the outlet of the first heat exchange tube bank and the first steam drum, so that the first steam drum and the first heat exchange tube bank c...

Embodiment 2

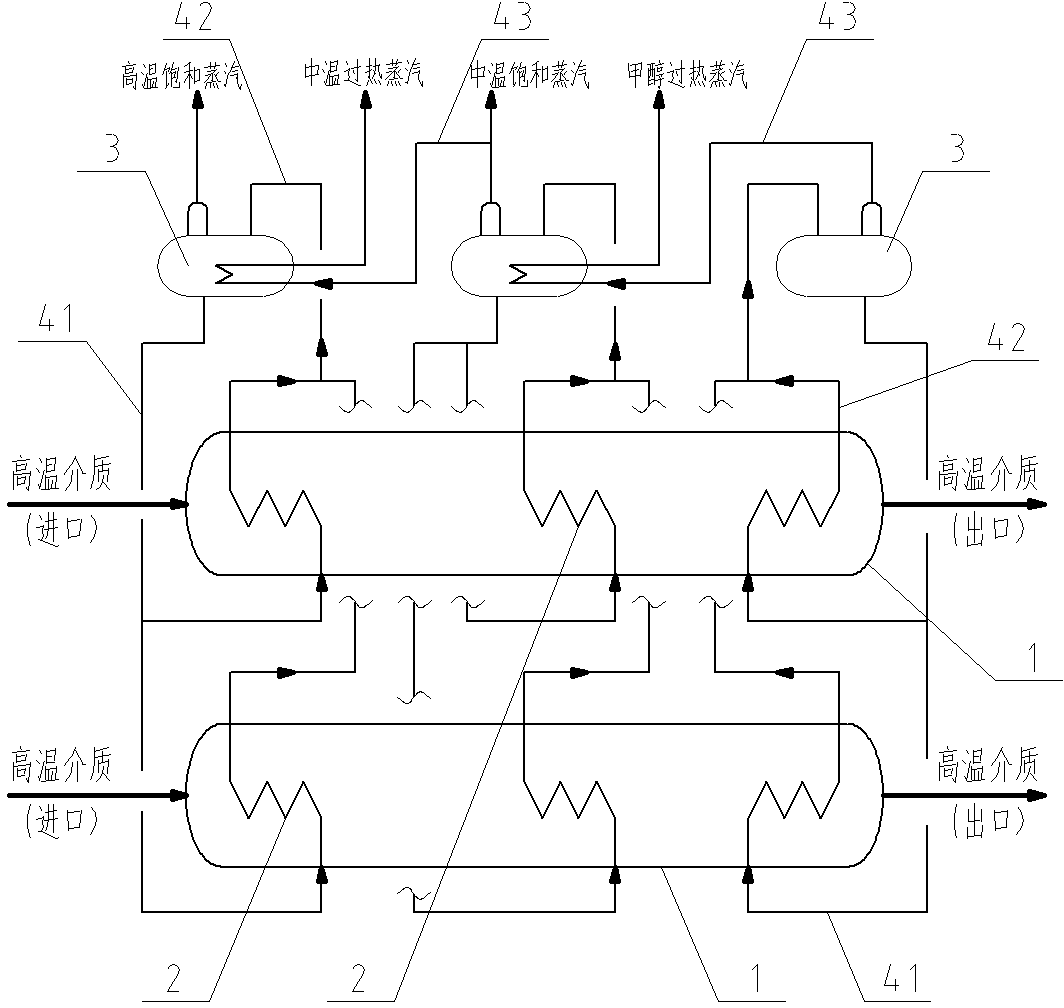

[0031] The system flow of embodiment 2 of the present invention is as figure 2As shown, the combined heat exchange system of this embodiment includes a shell 1 with a high-temperature medium inlet at one end and a high-temperature medium outlet at the other end. In this embodiment, the number of shells 1 is two, which is suitable for recycling multiple series of high-temperature For the heat of the medium, the inner wall of each shell 1 is equipped with heat insulating material, and each shell 1 is equipped with three heat exchange tube bundles 2 distributed in sequence along the flow direction of the high-temperature medium, and the shell 1 is equipped with passing pipes The three steam drums 3 connected with the heat exchange tube bundle 2, the temperature of the first steam drum is higher than the temperature of the second steam drum, and the temperature of the second steam drum is higher than the temperature of the third steam drum, different shells The heat exchange tube...

Embodiment 3

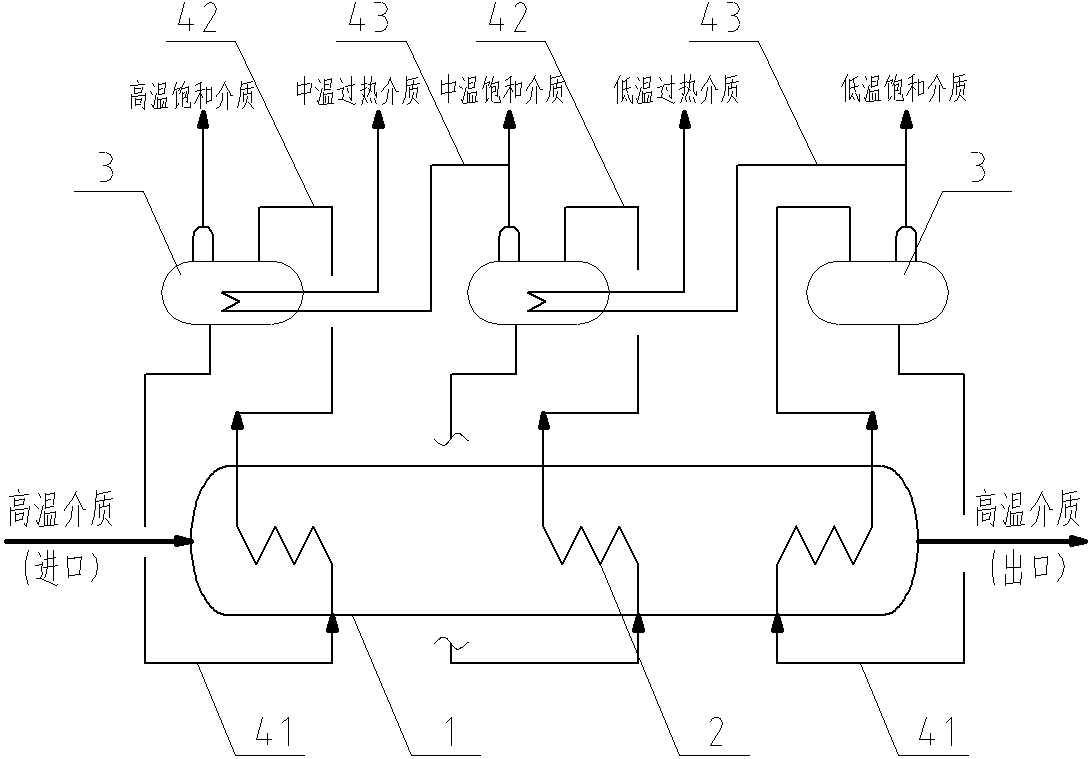

[0036] The system flow of embodiment 3 of the present invention is as image 3 As shown, the difference from Embodiment 2 of the present invention is that the number of shells in this embodiment is one, which is suitable for recovering the heat of a single series of high-temperature medium. The other structures of this embodiment are the same as those of Embodiment 3. Let me repeat.

[0037] Like Example 2, when this example is in use, the high-temperature medium flows in the shell, and part of the heat of the high-temperature medium is taken away by the medium in the heat exchange tube bank, and the medium in the first heat exchange tube bank is in the first cycle Finally, the heat of the medium in the first steam drum increases to obtain a high-temperature saturated medium, and the medium in the second heat exchange tube bank flows in the second cycle, and finally the heat of the medium in the second steam drum increases to obtain a medium Temperature-saturated medium, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com