Method for measuring content of silver in high-bismuth material

A determination method and content technology, which is applied in chemical analysis by titration, analysis by causing chemical reaction of materials, material analysis by observing the influence of chemical indicators, etc., can solve the problem of poor reproducibility of results, lack of consideration To avoid problems such as bismuth interference, achieve simple operation, avoid low measurement results, and improve precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

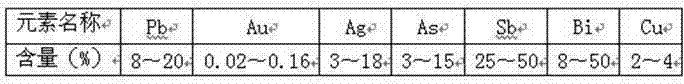

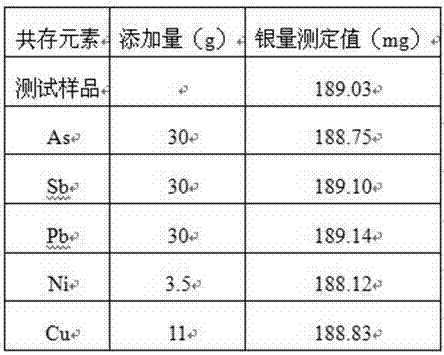

[0049] In this embodiment, a method for determining the silver content in a high-bismuth material uses bismuth oxide as a collector for precious metals, which can quantitatively capture the precious metals in the sample, and quantitatively measures the silver content in the sample by bismuth button direct titration; The specific operation steps are as follows:

[0050] 1) Ingredients: Prepare two samples A and B according to the ingredient ratio shown in Table 7, where sample A is added with a test sample, and the weight value of the test sample M=2.1167g is recorded, and sample B is not added with a test sample as a test Contrast, then, put into two test gold crucibles respectively;

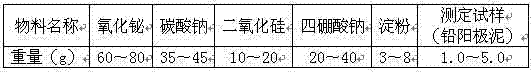

[0051] Table 7 The proportion of material ingredients in Example 1 of the assay method for silver content in a high-bismuth material

[0052]

[0053] 2) Melting: After the test gold melting furnace is pre-heated to 900°C, power off; open the furnace door, and put the test gold crucibles wit...

Embodiment 2

[0064] In this embodiment, a method for determining the silver content in a high-bismuth material uses bismuth oxide as a collector for precious metals, which can quantitatively capture the precious metals in the sample, and quantitatively measures the silver content in the sample by bismuth button direct titration; The specific operation steps are as follows:

[0065] 1) Ingredients: prepare two samples A and B according to the ingredient ratio shown in Table 8, wherein sample A is added with a test sample, and the weight value of the test sample M=4.8342g is recorded, and sample B is not added with a test sample as a test Contrast, then, put into two test gold crucibles respectively;

[0066] Table 8 The proportion of material ingredients in Example 2 of the assay method for silver content in a high-bismuth material

[0067]

[0068] 2) Melting: After the test gold melting furnace is pre-heated to 900°C, power off; open the furnace door, and put the test gold crucibles w...

Embodiment 3

[0079] In this embodiment, a method for determining the silver content in a high-bismuth material uses bismuth oxide as a collector for precious metals, which can quantitatively capture the precious metals in the sample, and quantitatively measures the silver content in the sample by bismuth button direct titration; The specific operation steps are as follows:

[0080] 1) Ingredients: Prepare two samples A and B according to the ingredient ratio shown in Table 9, wherein sample A is added with a test sample, and the weight value of the test sample M=1.0549g is recorded, and sample B is not added with a test sample as a test Contrast, then, put into two test gold crucibles respectively;

[0081] Table 9 The proportion of material ingredients in Example 3 of the assay method for silver content in a high-bismuth material

[0082]

[0083] 2) Melting: After the test gold melting furnace is pre-heated to 900°C, power off; open the furnace door, and put the test gold crucibles w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com