Reactor internal component critical heat flux real-time monitoring method based on sonic sensor

A technology of acoustic wave sensor and critical heat flow, which is applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of low surface emissivity of components, large temperature range, and large number of measuring points, so as to avoid low surface emissivity and solve the problem of Real-time monitoring, the effect of monitoring a large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solutions of the present invention in detail.

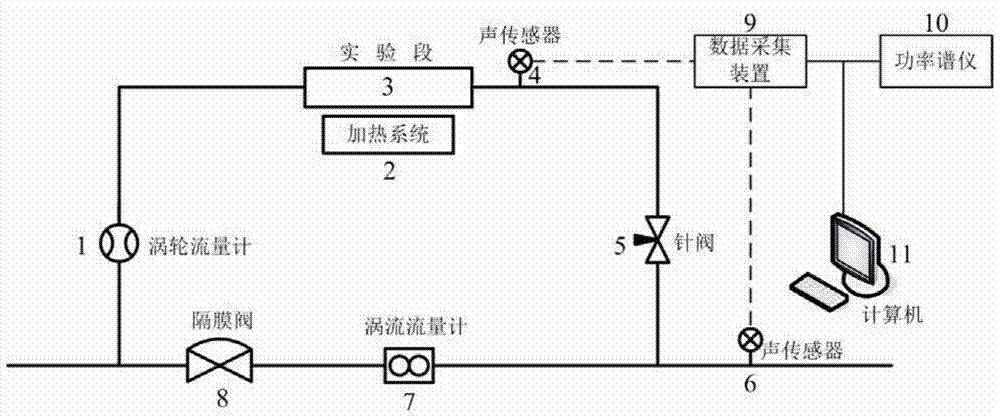

[0017] The specific implementation of the present invention is to use attached figure 1 Shown is an experimental system for acoustic monitoring of critical heat flow.

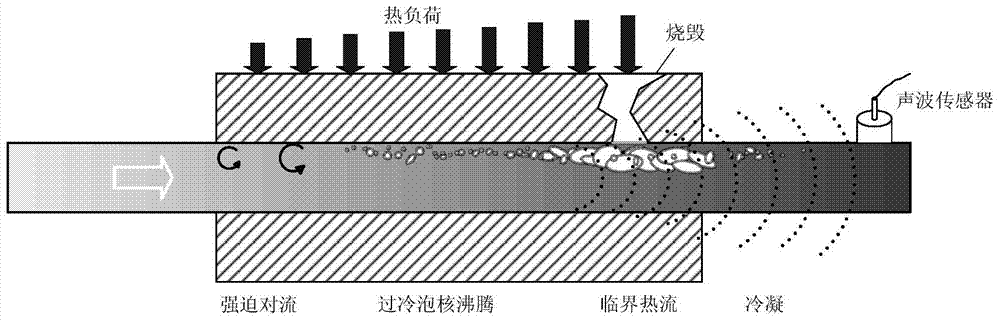

[0018] The acoustic wave monitoring critical heat flow experimental system used in the present invention includes a turbine flowmeter 1, a heating system 2, an experimental section 3, a first acoustic wave sensor 4, a needle valve 5, a second acoustic wave sensor 6, a vortex flowmeter 7, a diaphragm valve 8. Data acquisition device 9, power spectrometer 10, computer 11. The cooling water pipe equipped with the turbine flowmeter 1 is connected to the experimental section 3. The first acoustic wave sensor 4 and the needle valve 5 are installed on the outflow end pipe of the experimental section 3 to form a cooling water flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com