Foam-forming aerosol product

An aerosol and foam technology, which is used in medical preparations, cosmetic preparations, cosmetic preparations and other directions containing active ingredients, can solve problems such as inability to mix, explosion accidents, and inability to obtain storage stability, and achieves easy formation, The effect of high safety and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

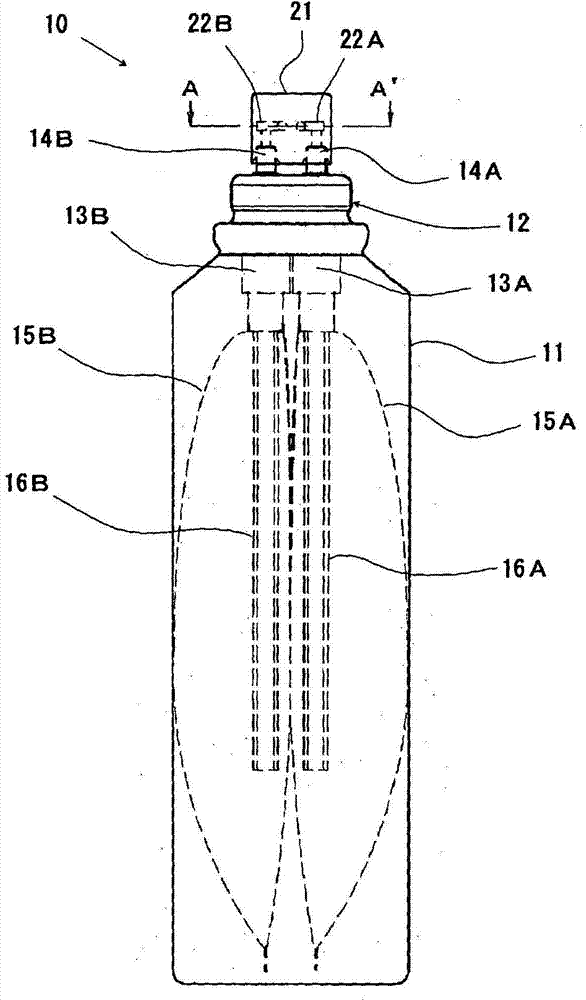

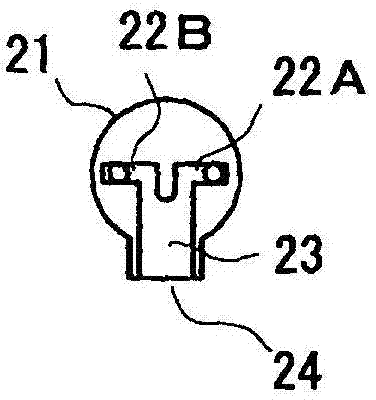

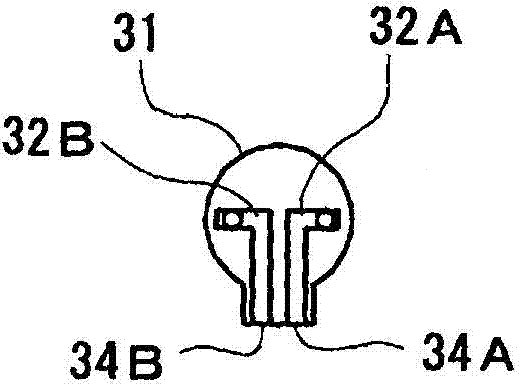

Image

Examples

Embodiment 1~ Embodiment 12 and comparative example 1

[0149] (Preparation of the first stock solution composition)

[0150] First, the paste base "EMACOL HD2146" (manufactured by Sanei Chemical Co., Ltd.) is heated at a temperature range of 80 to 85°C to obtain an oily solution (oil phase). On the other hand, purified water and Polyoxyethylene lauryl ether "BL-9EX" (manufactured by Nikko Chemicals Co., Ltd.) as an active agent is mixed with other raw materials for the first stock solution composition if necessary, and heated at a temperature range of 80 to 85°C , thus obtaining an aqueous solution (aqueous phase).

[0151] Next, the obtained oily solution (oil phase) was stirred under the condition of a stirring speed (rotational speed) of 600 rpm using a blade stirrer, and the obtained water-soluble solution (water phase) was slowly added to the oily solution, thereby Prepare emulsion. Then, after cooling the obtained emulsion until the liquid temperature became 30° C. or lower, an organic acid was added and stirred at a stirr...

Embodiment 1

[0159] In Example 1, in the filling space for the first stock solution (inside the first inner bag) of the dual-structure container, instead of the first stock solution composition, it is filled in the process of preparing the first stock solution composition related to Example 1. , and in the filling space for the second stock solution (in the second inner bag), instead of the second stock solution composition, the emulsion obtained in the preparation process of the second stock solution composition related to this Example 1 is filled , except that, a comparative aerosol product was produced in the same manner as in Example 1.

[0160]

[0161] Regarding each of the aerosol products produced in Examples 1 to 12, Comparative Example 1, and Comparative Example 2 described above, the foaming property of discharge was evaluated by the following method. The results are shown in Table 1 and Table 2.

[0162] (foaming in discharge)

[0163] Spray 5 g of the content of the aeroso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com