Solar thermal power generation equipment

A technology of thermal power generation and solar energy, which is applied in the direction of solar thermal energy, solar collectors, solar heating systems, etc., and can solve problems such as large construction expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

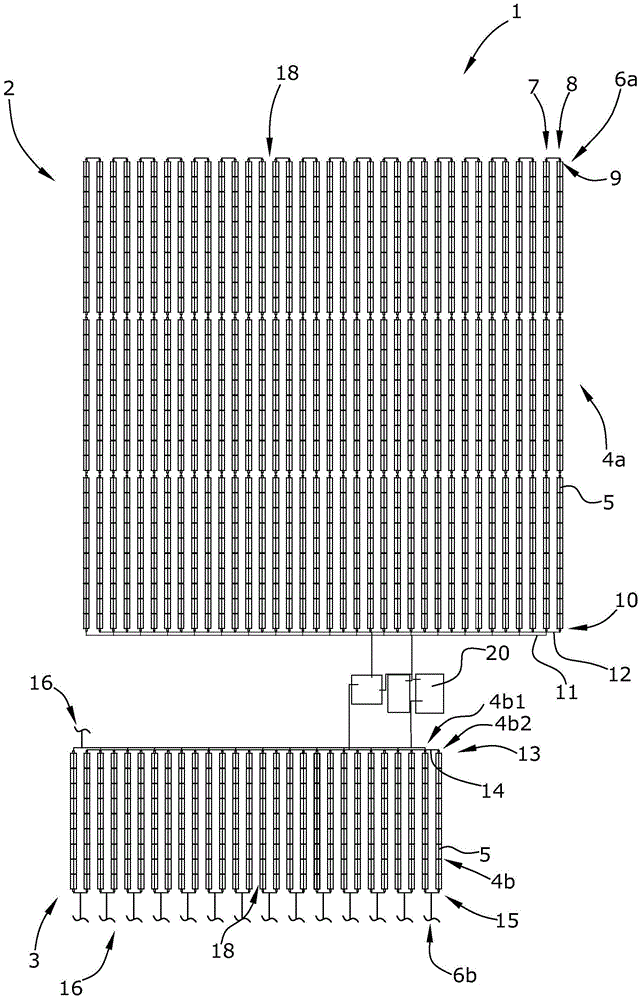

[0025] The solar thermal power plant 1 is composed of an evaporator 2 and a superheater 3 .

[0026] The evaporator 2 is formed by a first number of parabolic trough collectors 4 and the superheater 3 is formed by a second number of parabolic trough collectors 4 .

[0027] Each parabolic trough collector 4 consists of several parabolic trough segments 5 . In this configuration, the parabolic trough collectors 4 a of the evaporator 2 are each formed from ten parabolic trough segments 5 , while the parabolic trough collectors 4 b of the superheater 3 are each formed from nine parabolic trough segments 5 .

[0028] The parabolic trough collectors 4a, 4b are arranged in several annular structures 6a, 6b connected in parallel. In this arrangement, the annular structure 6a of the evaporator 2 is formed by six parabolic trough collectors 4a in each case. The annular structure 6b of the superheater 3 is formed in each case by two parabolic trough collectors 4b.

[0029] The annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com