Method for reducing polymers generated in frying process of frying oil

A frying oil and polymer technology, which is applied in food science, edible oil/fat, application, etc., can solve the problems of high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Frying experiment:

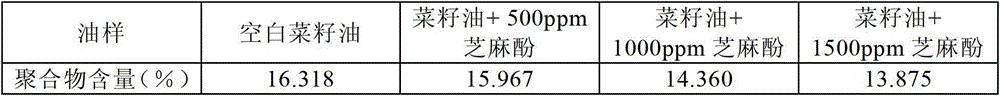

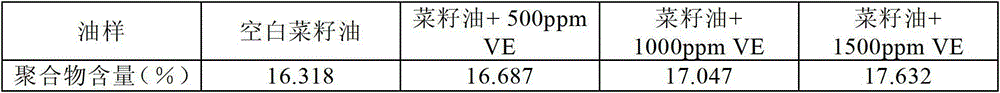

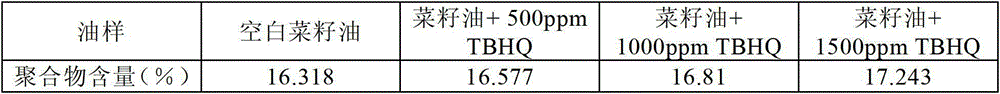

[0035]Take a 2500g blank rapeseed oil sample (purchased from Shanghai Kerry Food Industry Co., Ltd.), place it in a constant temperature fryer, heat it to 180°C, and carry out the frying experiment of French fries after constant temperature. In the morning, fry 10 pots, 200g French fries in each pot, and fry for 3 minutes. Take 100g of oil sample for every 10 pots. After frying, cook for 2 hours. In the afternoon, fry another 10 pots, and use the same method to take 100g of oil samples for every 10 pots. A total of 20 pots were fried in one day, and 40 pots were fried for 2 days in total. The oil samples after frying 40 pots were tested for polymer indicators (tested according to AOCS cd22-91). The results are shown in Table 1 below.

Embodiment 1-3

[0037] Preparation of oil samples:

[0038] Add 500ppm, 1000ppm and 1500ppm sesamol to 2500g non-antioxidant rapeseed oil (that is, primary refined rapeseed oil without any antioxidant added, purchased from Shanghai Merrill Chemical Technology Co., Ltd.) respectively, and prepare the frying experiment Use an oil sample.

[0039] Frying experiment:

[0040] 2500g oil samples for frying experiment were taken respectively, and the frying experiment was carried out according to the frying experiment method described in Comparative Example 1. The results are shown in Table 1 below.

Embodiment 2

[0060] The frying experiment was carried out as described in Comparative Example 1, except that a blank soybean oil sample (purchased from Shanghai Kerry Food Industry Co., Ltd.) was used instead of a blank rapeseed oil sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com