Injection octreotide acetate lyophilized composition and preparation method thereof

A technology of octreotide acetate and composition, applied in the field of octreotide acetate freeze-dried composition for injection and preparation thereof, can solve the problems of difficult industrialization, microbial contamination, poor stability and the like, achieve easy industrial production, simple preparation process, high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

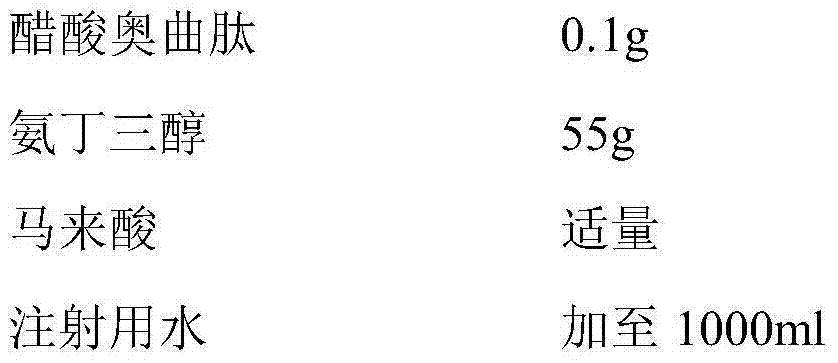

Embodiment 1

[0023]

[0024] Preparation Process:

[0025] Bottle washing, sterilizing and drying: the vials are first cleaned by an ultrasonic bottle washing machine, then sterilized and dried by a sterilizing dryer, and sent to the filling room for later use.

[0026] Butyl rubber stopper treatment: After the butyl rubber stopper is cleaned by a rubber stopper cleaning machine, it is sterilized by steam at 121°C for 30 minutes, and dried for later use.

[0027] Aluminum-plastic cover treatment: wash the aluminum-plastic cover with an aluminum cover washing machine, sterilize, dry, and take it out for use.

[0028] Preparation of the liquid medicine: Weigh the prescribed amount of octreotide acetate and trometamol into water for injection cooled to 15°C, stir to dissolve, add an appropriate amount of maleic acid, adjust the pH value of the liquid medicine to 4.5, circulate and filter, and send samples to test the semi-finished product For the content of the liquid medicine, the liquid...

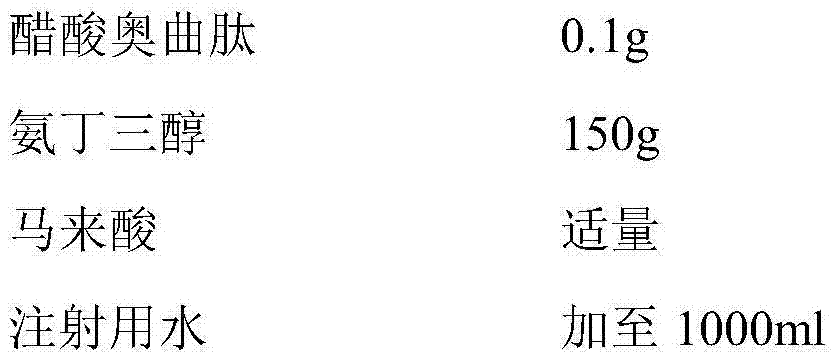

Embodiment 2

[0032]

[0033] Preparation Process:

[0034] Bottle washing, sterilizing and drying: the vials are first cleaned by an ultrasonic bottle washing machine, then sterilized and dried by a sterilizing dryer, and sent to the filling room for later use.

[0035] Butyl rubber stopper treatment: After the butyl rubber stopper is cleaned by a rubber stopper cleaning machine, it is sterilized by steam at 121°C for 30 minutes, and dried for later use.

[0036] Aluminum-plastic cover treatment: wash the aluminum-plastic cover with an aluminum cover washing machine, sterilize, dry, and take it out for use.

[0037] Preparation of the liquid medicine: Weigh the prescribed amount of octreotide acetate and trometamol into the water for injection cooled to 20°C, stir to dissolve, add an appropriate amount of maleic acid, adjust the pH value of the liquid medicine to 5.0, circulate and filter, and send samples to test the semi-finished products For the content of the liquid medicine, the l...

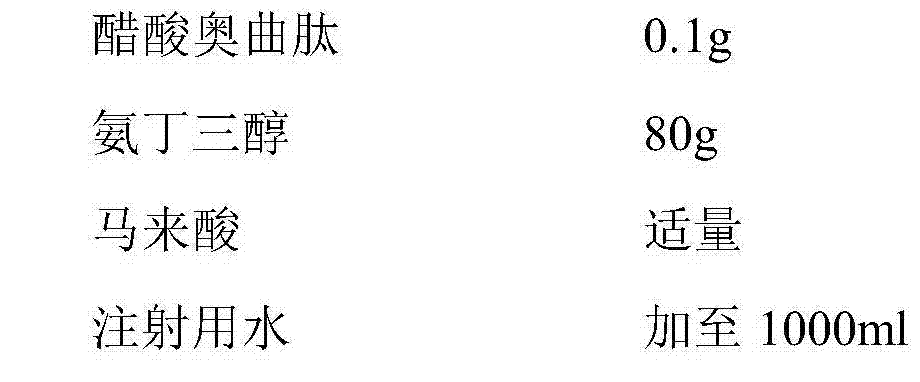

Embodiment 3

[0041]

[0042] Preparation Process:

[0043] Bottle washing, sterilizing and drying: the vials are first cleaned by an ultrasonic bottle washing machine, then sterilized and dried by a sterilizing dryer, and sent to the filling room for later use.

[0044] Butyl rubber stopper treatment: After the butyl rubber stopper is cleaned by a rubber stopper cleaning machine, it is sterilized by steam at 121°C for 30 minutes, and dried for later use.

[0045] Aluminum-plastic cover treatment: wash the aluminum-plastic cover with an aluminum cover washing machine, sterilize, dry, and take it out for use.

[0046] Preparation of the liquid medicine: Weigh the prescribed amount of octreotide acetate and trometamol into the water for injection cooled to 15°C, stir to dissolve, add an appropriate amount of maleic acid, adjust the pH value of the liquid medicine to 4.5, circulate and filter, and send samples for testing For the content of the semi-finished product, the liquid with a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com