Special power system for filament micro connection

A power supply system and micro-connection technology, applied in welding power supply, welding power supply, etc., can solve the problems of inability to accurately control the welding heating process, inability to control current, and difficulty in application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

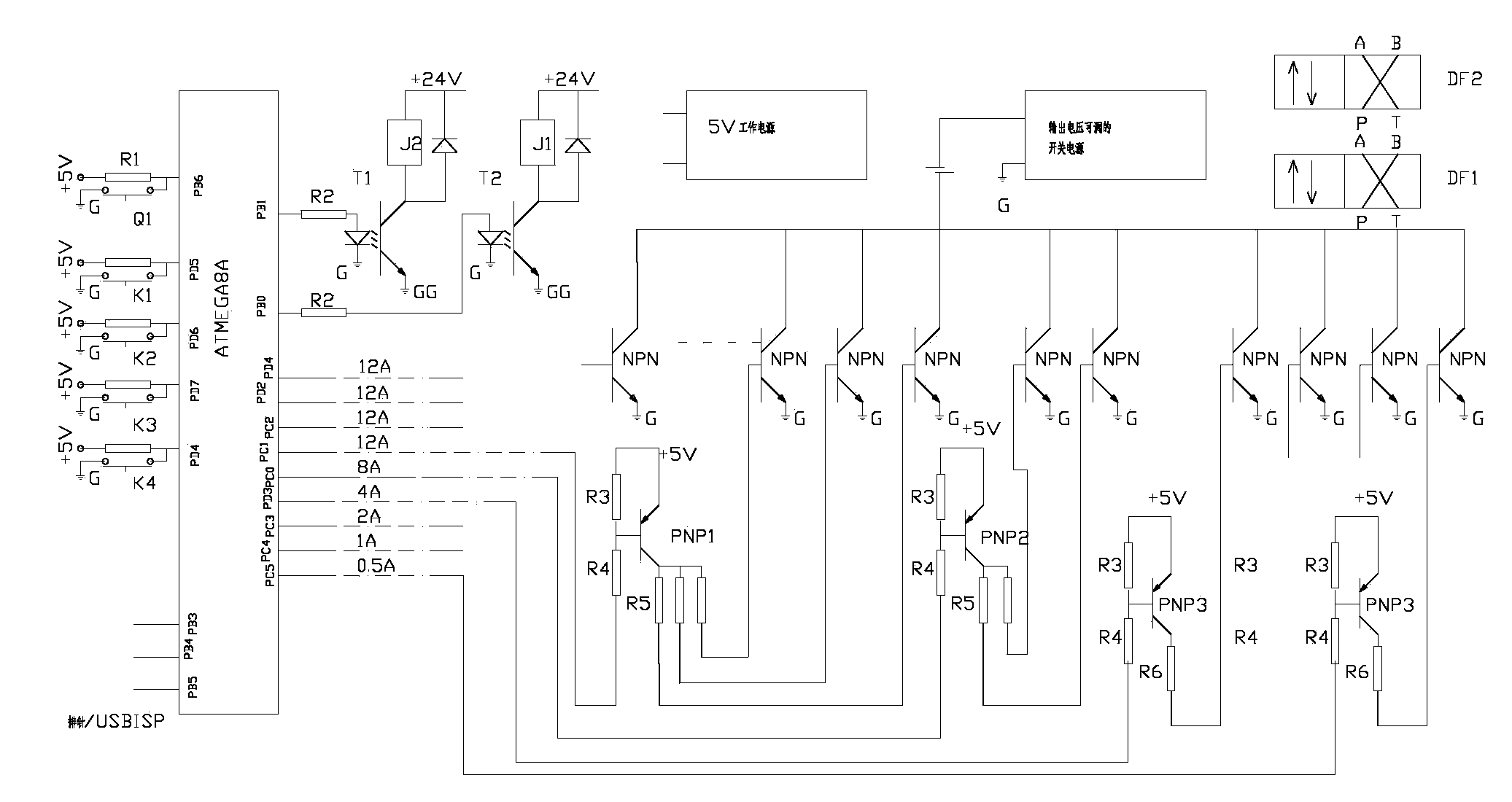

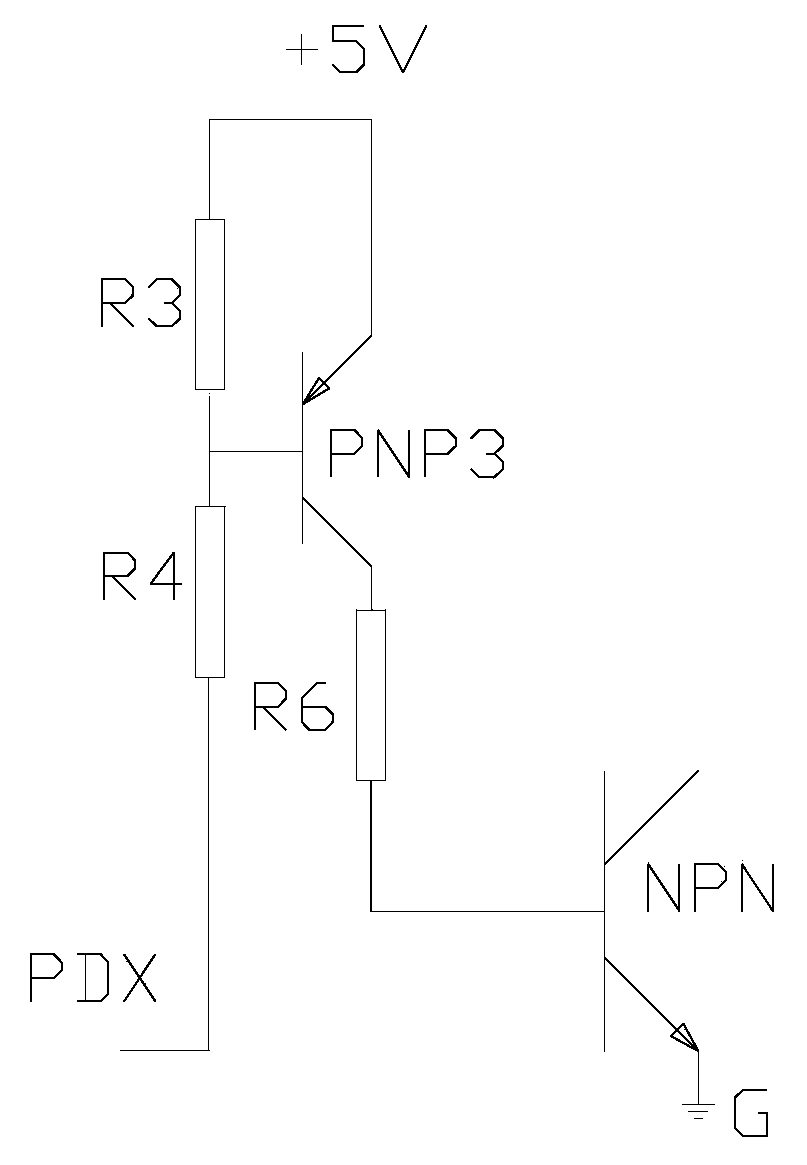

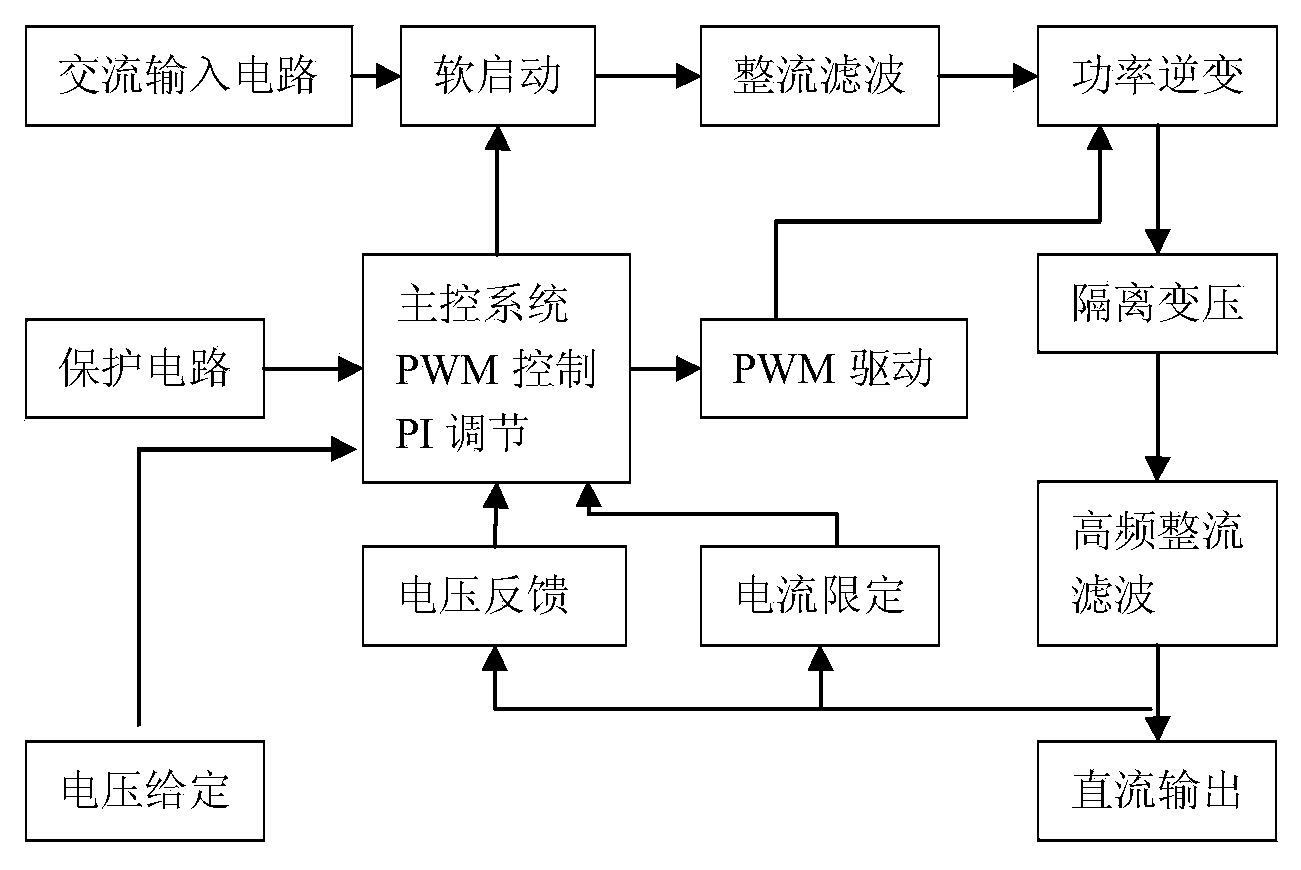

[0026] The invention consists of two parts: an inverter high-power switching power supply with adjustable output voltage and an arbitrary current waveform output circuit, see figure 1 , the arbitrary current waveform output circuit is composed of a single-chip microcomputer and 9 constant current circuits formed by power transistors ( figure 1 There are 4 concretely presented in ), and the 9 IO ports of the single-chip microcomputer control the switching state of the power transistor, which realizes the arbitrary control of the current output waveform within a certain period of time when the micro-connection is energized, making it possible to use the best current waveform filament connection, ensuring It outputs constant current according to a given value, and opens up a new current waveform arbitrary control spot welding method. It is an ideal precision resistance therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com