A Layered Slicing Method Based on Selective Laser Sintering

A technology of laser sintering and layered slicing, which is applied in laser welding equipment, improvement of process efficiency, image data processing, etc., can solve problems such as low molding efficiency and error of molded parts, improve precision, improve production efficiency and production The effect of quality and guaranteed molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

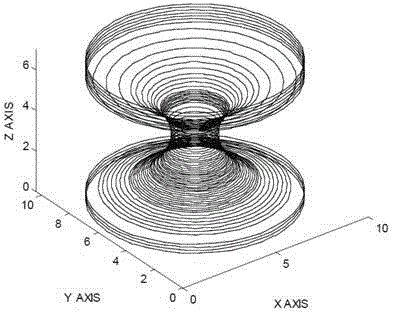

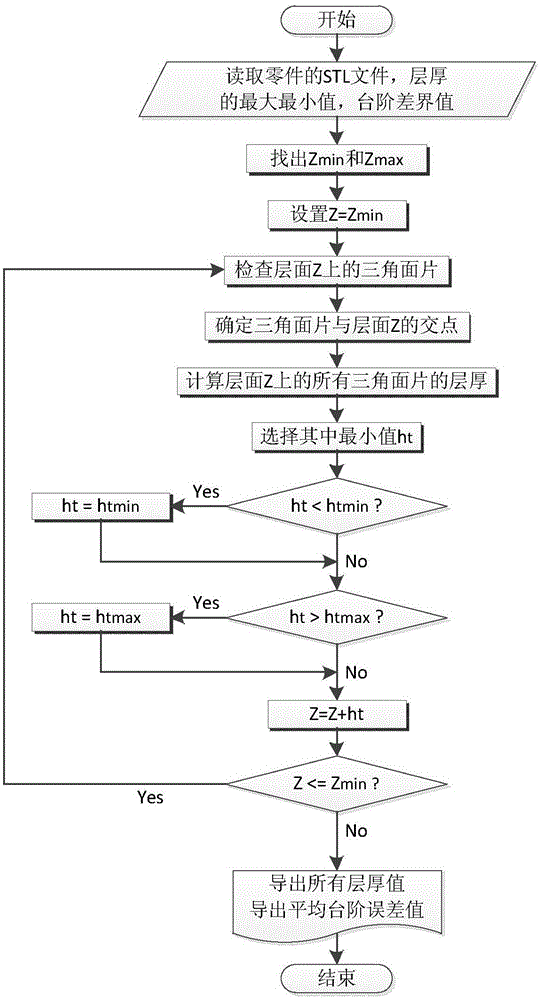

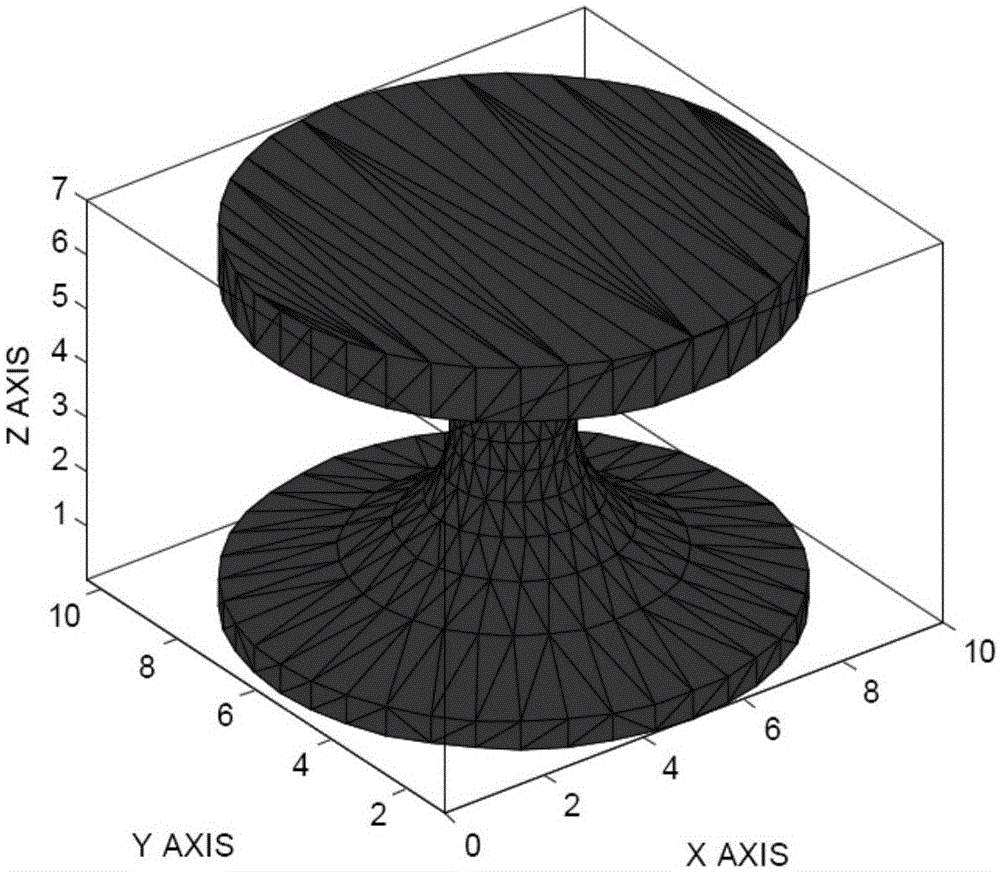

[0038] Such as figure 1 , 2 , 3, and 4, a layered slicing method based on selective laser sintering, comprising the following steps:

[0039] (1) Read the STL file generated by the CAD part drawing to be processed;

[0040] (2) Determine the delamination direction, the maximum and minimum values of the delamination thickness, the maximum value of the step error and the maximum value of the surface roughness;

[0041] (3) slice the triangular face in the STL model in the layering direction for the first layer;

[0042](4) Calculate the minimum layer thickness of the next layer that meets the accuracy requirements according to each side of the layer plane outline polygon and each triangle surface related to it, and the specific steps are as follows:

[0043] Let the maximum and minimum coordinates of the triangular patch of the STL model in the layering direction be Z max and Z min , the maximum allowable step error is δ max , the extreme surface roughness is R b , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com