Conveyor rubber belt longitudinal tearing detecting system and detecting method based on ultrasonic waves

A technology of longitudinal tearing and detection system, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of high on-site environment requirements, poor detection results, and high cost of detection devices, and achieve detection results. Good, avoid economic losses, good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

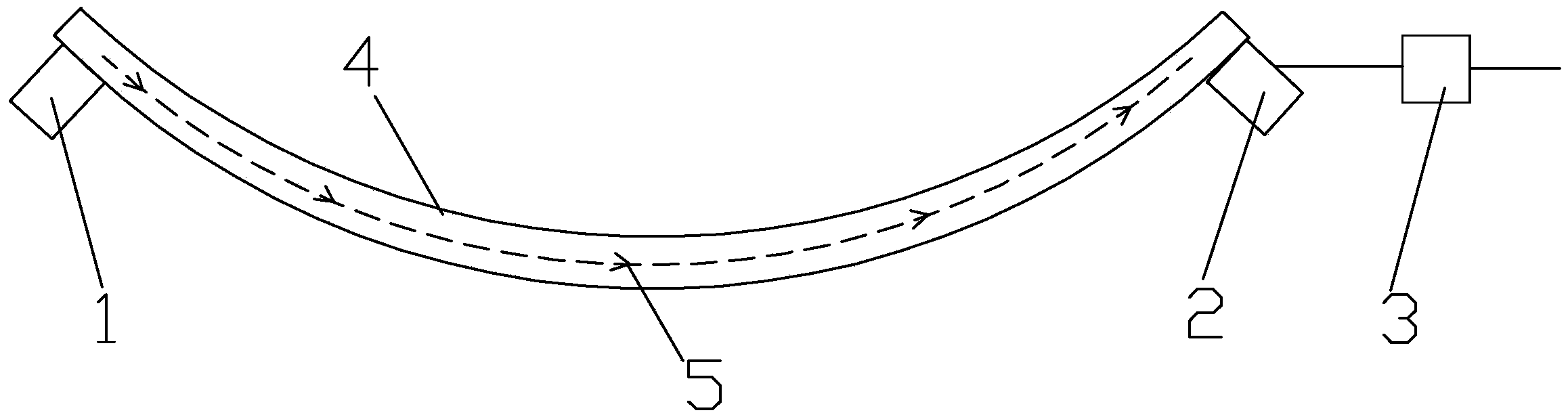

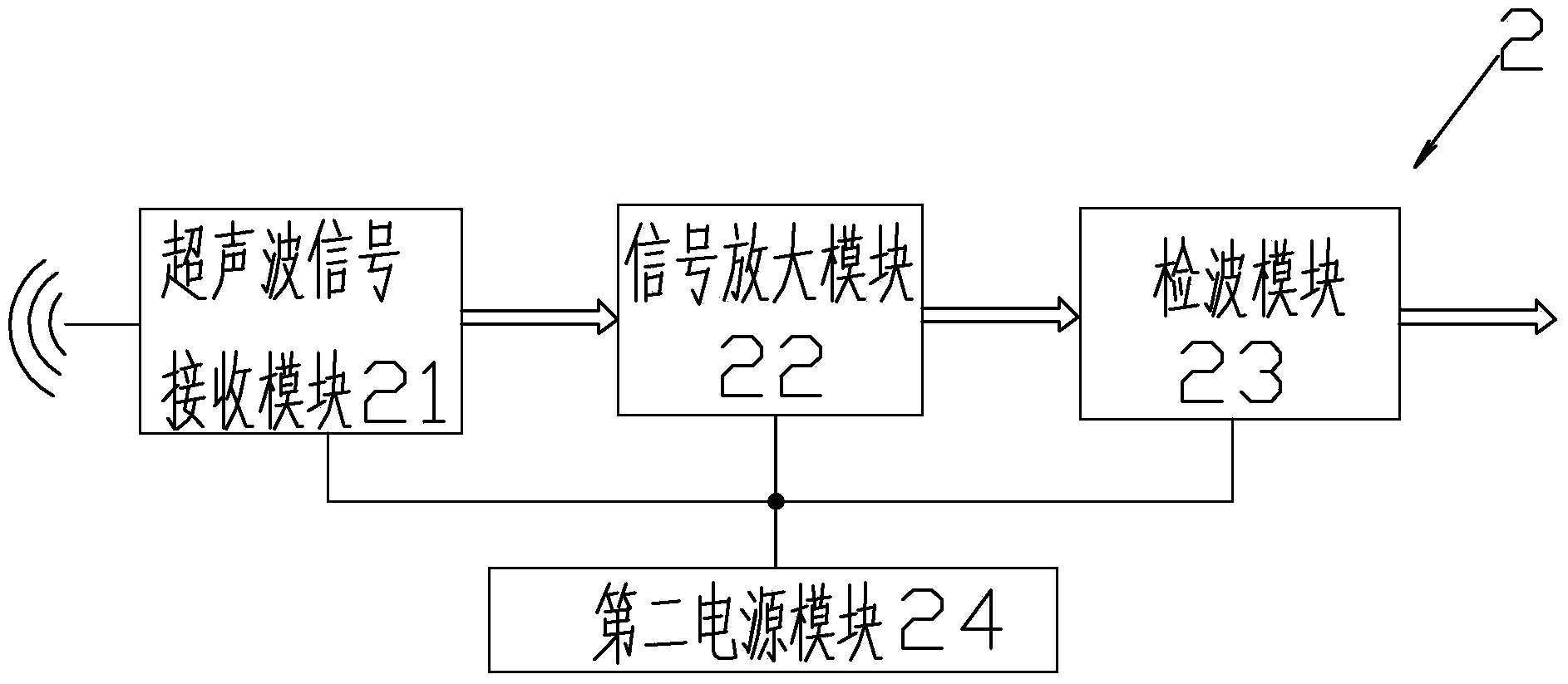

[0030] See figure 1 , The ultrasonic-based conveyor belt longitudinal tear detection system of this embodiment is mainly composed of an ultrasonic signal generating device 1, an ultrasonic signal receiving device 2 and an ultrasonic signal analyzing device 3.

[0031] The ultrasonic signal generating device 1 is installed at one end of the conveyor belt 4; the ultrasonic signal receiving device 2 is installed at the other end of the conveyor belt 4; the ultrasonic signal analyzing device 3 and the ultrasonic signal receiving device 2 are arranged nearby.

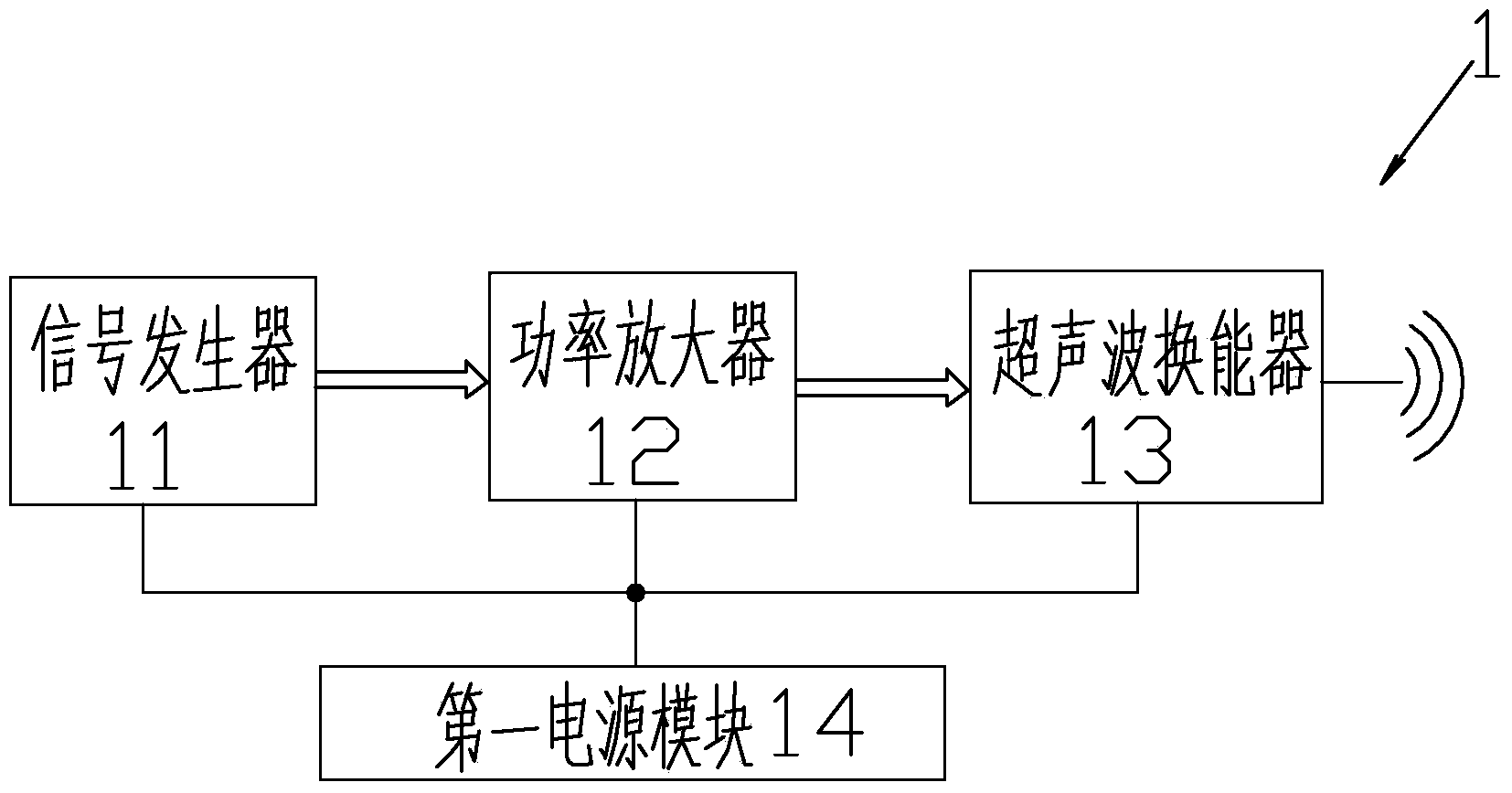

[0032] See figure 2 , The ultrasonic signal generating device 1 is mainly composed of a signal generator 11 , a power amplifier 12 , an ultrasonic transducer 13 and a first power module 14 .

[0033] Signal generator 11 is provided with signal output end; Power amplifier 12 is provided with signal input end and signal output end; Ultrasonic transducer 13 is provided with electrical signal input end and ultrasonic signal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com