Multi-core optical fiber manufacturing method

A manufacturing method and technology for multi-core optical fibers, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of increased splicing loss and the inability to precisely fix the core rod, achieve accurate relative positions, reduce the probability of bubbles and bright spots, The effect of saving cladding material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

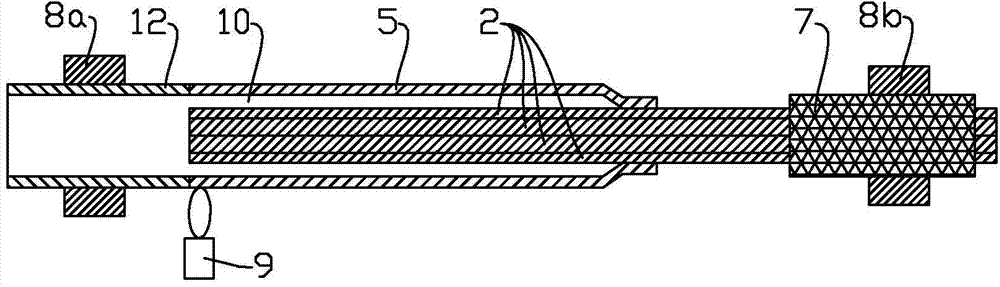

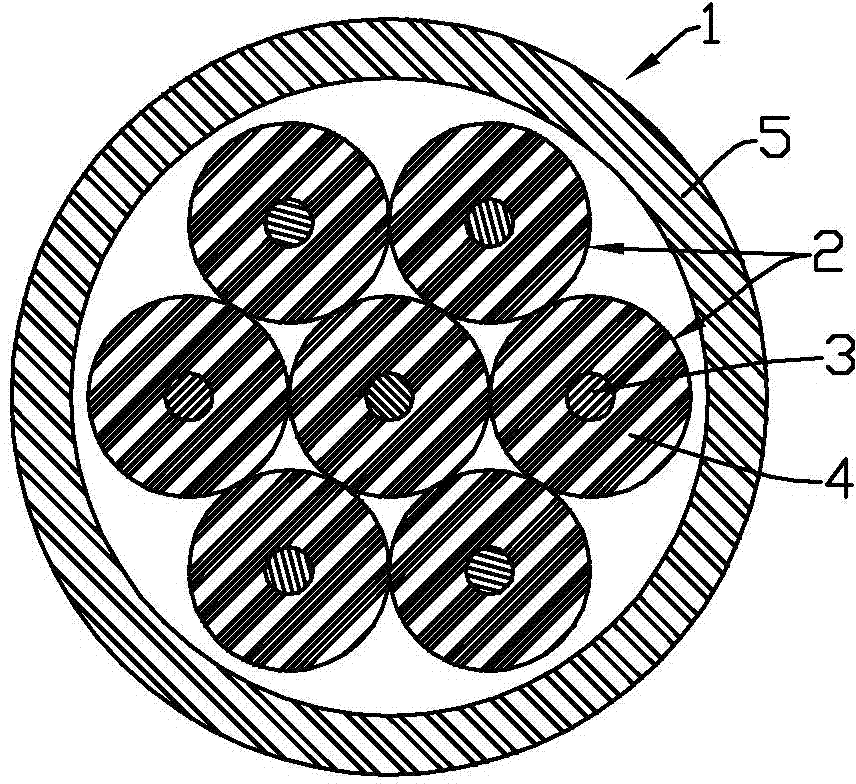

[0027]The mandrel 2 is produced by the VAD process, the refractive index difference Δ is 0.35%, the ratio b / a of the diameter of the cladding layer 4 to the diameter of the core layer 3 is 4.0, its outer diameter is 8 mm after stretching, and it is cut into lengths of 7 mandrels of 1000mm. The seven mandrels 2 are fixed on the clamp 7 after pickling and flame polishing, and the clamp 7 is further installed on the chuck 8b. Then the bushing 5 (with a specification of Φ32mm*2.5mm*800mm) that has been pickled and flame polished is installed on another chuck 8a of the lathe. Next, the plurality of mandrels 2 are slowly moved toward the chuck 8 a, so that the mandrels 2 are inserted into the sleeve 5 , and the ends of the mandrels 2 extend to the interface between the sleeve 5 and the transition sleeve 12 . Rotate the synchronized chucks 8a and 8b at 30 rpm. Move the torch 9 to the end of the sleeve 5 near the clamping end of the mandrel 2 to heat, and the temperature is controll...

Embodiment 2

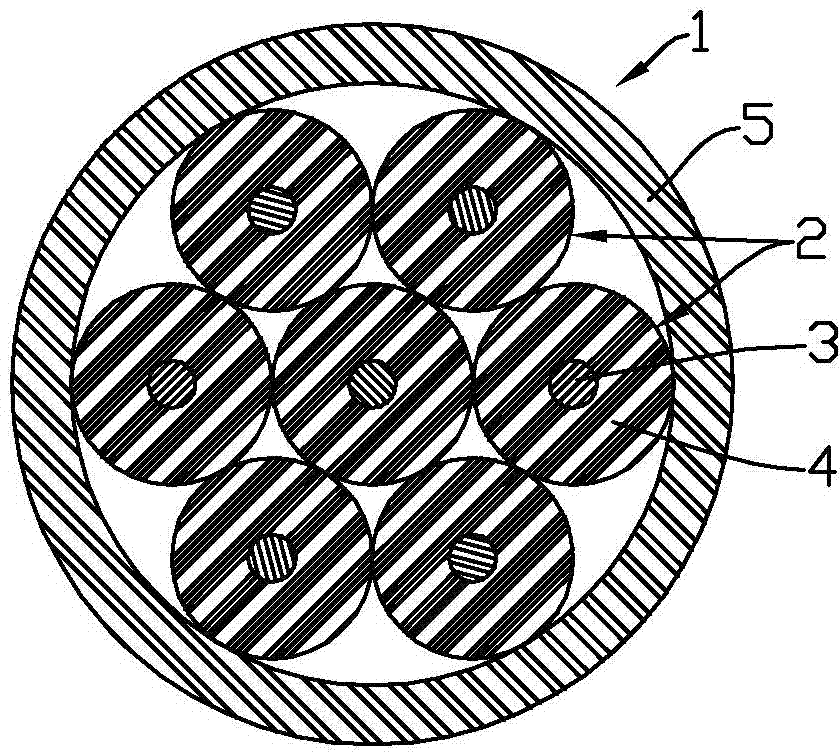

[0030] Mandrel 2 is produced by MCVD+solution immersion process, and the core layer 3 components are SiO2-Al2O3-Er2O3. The core rod 2 has a refractive index difference Δ of 0.32%, an outer diameter of 5 mm, and a length of 700 mm. The 19 mandrels 2 are fixed on the clamp 7 after pickling and flame polishing, and the clamp 7 is further installed on the chuck 8b. Then the bushing 5 (with a specification of Φ32mm*2.5mm*500mm) that has been pickled and flame polished is installed on another chuck 8a of the lathe. Next, according to the method of Example 1, the assembly of the mandrel and the casing and the online wire drawing are completed. After the optical fiber preform of this embodiment is drawn into the optical fiber 15, the cross-sectional view of the bare optical fiber 1'' with the coating layer stripped is shown in Figure 8 As shown, the optical fiber cladding contains 19 core layers 3''.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com