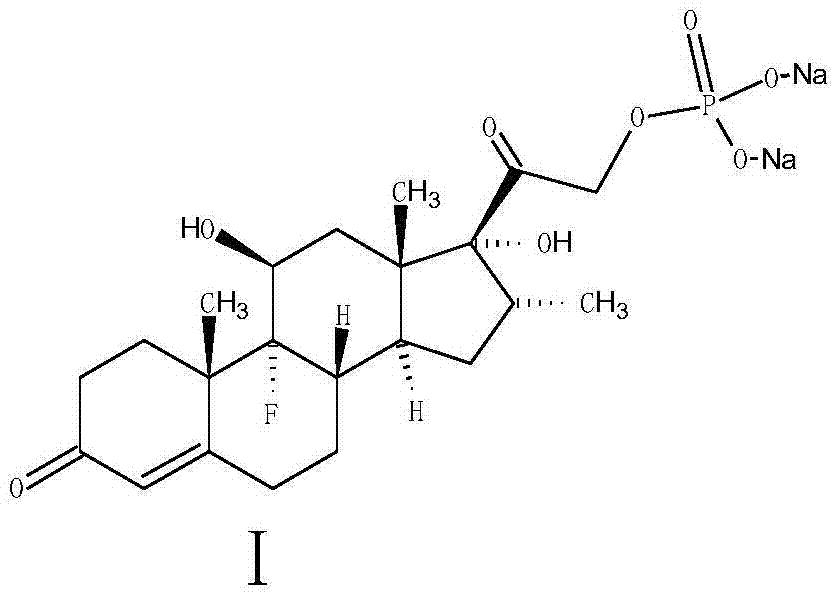

Improved preparation method of dexamethasone sodium phosphate intermediate

A technology of dexamethasone sodium phosphate and dexamethasone phosphate, applied in the direction of steroids, organic chemistry, etc., can solve the problems of incomplete reaction of dexamethasone, reduction of product purity, increase of side reactions, etc., and achieve good industrial application Foreground, increasing organic solvent extraction, effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

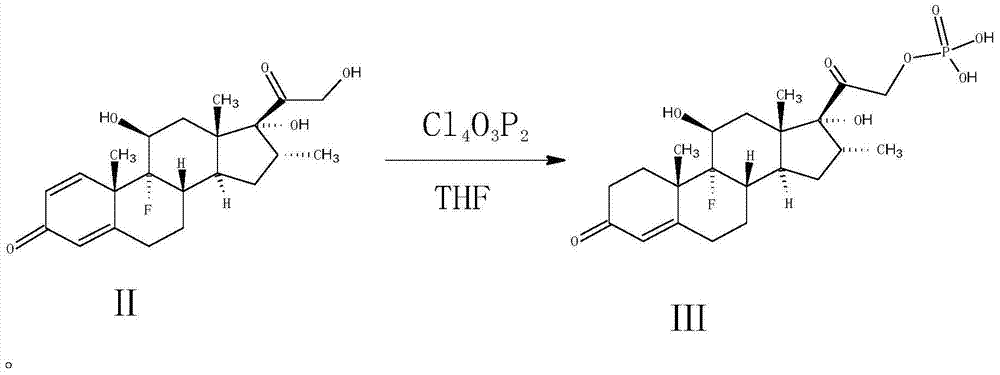

Method used

Image

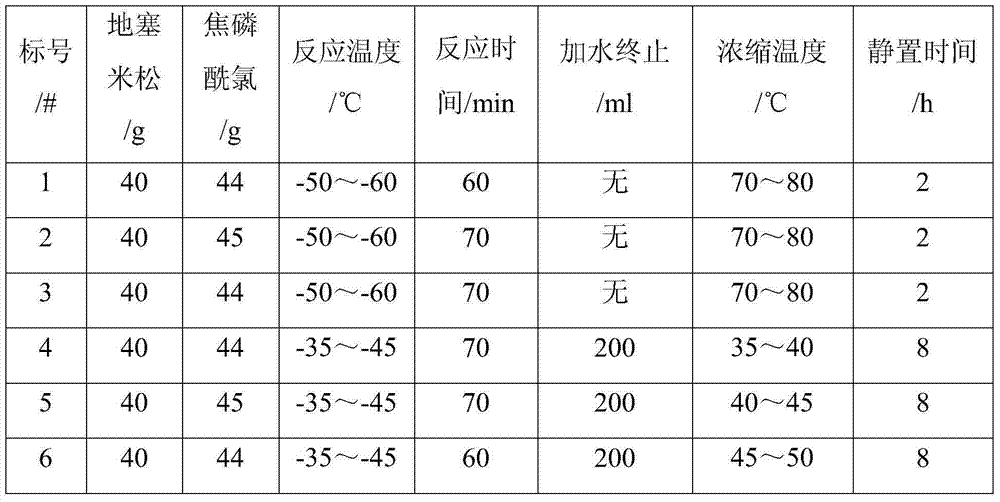

Examples

Embodiment 1

[0041] (A) In a 500ml four-necked reaction flask, add 20g dexamethasone, 200ml tetrahydrofuran, and ventilate nitrogen. Under stirring, the temperature is controlled to -45℃~-55℃, 22g pyrophosphoryl chloride is added dropwise, and the temperature is increased to -35. ℃~-45℃, heat preservation reaction for 1h;

[0042] (B) Control the temperature to -30℃~-45℃, add 100ml purified water dropwise to stop the reaction, slowly add the reaction solution to a 2000ml four-necked reaction flask containing 580ml ice water; after the addition, slowly add 100g hydrogen carbonate Sodium, control the temperature to 5℃~10℃ and stir for 2h;

[0043] (C) Filter, rinse the filtered sodium bicarbonate with 200ml of purified water, combine the eluent with the filtrate, and concentrate the combined solution under reduced pressure at 40°C to 45°C until there is no tetrahydrofuran;

[0044] (D) After concentration, cool to 10℃~20℃, add 180ml ethyl acetate to extract 3 times, separate into layers, add activ...

Embodiment 2

[0048] (A) In a 250ml four-necked reaction flask, add 10g of dexamethasone, 120ml of tetrahydrofuran, and aeration of nitrogen. While stirring, the temperature is controlled to -45℃~-55℃, and 12g of pyrophosphoryl chloride is added dropwise, and the temperature is increased to -35. ℃~-45℃, heat preservation reaction for 1h;

[0049] (B) Control the temperature to -30℃~-40℃, add 50ml purified water dropwise to stop the reaction, slowly add the reaction solution to a 1000ml four-necked reaction flask containing 350ml ice water; after the addition, slowly add 60g hydrogen carbonate Sodium, control the temperature to 5℃~10℃ and stir for 2.5h;

[0050] (C) Filter, rinse the filtered sodium bicarbonate with 100ml of purified water, combine the eluent with the filtrate, and concentrate the combined solution under reduced pressure at 40°C to 45°C until there is no tetrahydrofuran;

[0051] (D) After concentrating, cool to 10℃~20℃, add 90ml ethyl acetate to extract 3 times, separate into lay...

Embodiment 3

[0055] (A) In a 1000ml four-necked reaction flask, add 40g dexamethasone, 450ml tetrahydrofuran, and ventilate nitrogen. Under stirring, the temperature is controlled to -45℃~-55℃, and 45g pyrophosphoryl chloride is added dropwise, and the temperature is increased to -35. ℃~-45℃, keep warm for 75min;

[0056] (B) Control the temperature to -30℃~-45℃ and add 400ml purified water dropwise to stop the reaction, slowly add the reaction solution to a 3000ml four-necked reaction flask containing 1200ml ice water; after the addition, slowly add 250g hydrogen carbonate Sodium, control the temperature to 5℃~10℃ and stir for 2h;

[0057] (C) Filter, rinse the filtered sodium bicarbonate with 400ml of purified water, combine the eluent with the filtrate, and concentrate the combined solution under reduced pressure at 40°C to 45°C until there is no tetrahydrofuran;

[0058] (D) After concentrating, cool to 10℃~20℃, add 360ml ethyl acetate to extract 3 times, separate into layers, add activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com