Low-cost high-performance insulating rubber material

A high-performance, low-cost technology, used in rubber insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems affecting insulation strength, electrical properties, and can not guarantee the service life of cables, etc. High strength, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

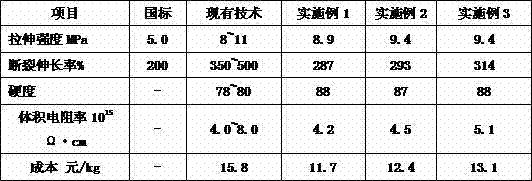

Examples

specific Embodiment 1

[0025] A low-cost high-performance insulating rubber material disclosed by the present invention is selected from 60 parts of EPDM rubber, 40 parts of POE, 2 parts of dicumyl peroxide, 1 part of TAIC, 15 parts of plasticizer, and 2 parts of anti-aging agent. 150 parts, 150 parts of talcum powder, 50 parts of pottery clay, 4 parts of white carbon black.

[0026] Put the above materials (except dicumyl peroxide and TAIC) into the internal mixer and knead for 2~3 minutes, lift the top bolt to sweep the material, repeat twice, and then continue kneading until the temperature shows 120°C. The rubber is discharged to the open mill and mixed by turning over the bag, and the rubber is filtered by the rubber filter, and then the strips are not opened, and then put into the internal mixer after cooling, adding dicumyl peroxide and TAIC, and the mixing time is 1~2min. The strips are cut out on the three-roller laminator, and the finished product is put into the continuous sulfur workshop...

specific Embodiment 2

[0027] A low-cost high-performance insulating rubber material disclosed by the present invention is selected from 70 parts of EPDM rubber, 30 parts of ethylene octene, 3.5 parts of dicumyl peroxide, 1.5 parts of TAIC, 12 parts of plasticizer, 3 parts of anti-aging agent, 135 parts of talcum powder, 65 parts of pottery clay, and 5 parts of white carbon black.

[0028] Put the above materials (except dicumyl peroxide and TAIC) into the internal mixer and knead for 2~3 minutes, lift the top bolt to sweep the material, repeat twice, and then continue kneading until the temperature shows 120°C. The rubber is discharged to the open mill and mixed by turning over the bag, and the rubber is filtered by the rubber filter, and then the strips are not opened, and then put into the internal mixer after cooling, adding dicumyl peroxide and TAIC, and the mixing time is 1~2min. The strips are cut out on the three-roller laminator, and the finished product is put into the continuous sulfur wo...

specific Embodiment 3

[0029] A low-cost high-performance insulating rubber material disclosed by the present invention is selected from 80 parts of EPDM rubber, 20 parts of ethylene octene, 4.5 parts of dicumyl peroxide, 2 parts of TAIC, 10 parts of plasticizer, 5 parts of anti-aging agent, 120 parts of talcum powder, 80 parts of pottery clay, and 6 parts of white carbon black.

[0030] Put the above materials (except dicumyl peroxide and TAIC) into the internal mixer and knead for 2~3 minutes, lift the top bolt to sweep the material, repeat twice, and then continue kneading until the temperature shows 120°C. The rubber is discharged to the open mill and mixed by turning over the bag, and the rubber is filtered by the rubber filter, and then the strips are not opened, and then put into the internal mixer after cooling, adding dicumyl peroxide and TAIC, and the mixing time is 1~2min. The strips are cut out on the three-roller laminator, and the finished product is put into the continuous sulfur work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com