A kind of anti-corrosion wear-resisting repairing material

A repair material, anti-corrosion and wear-resistant technology, applied in the field of materials, can solve problems such as corrosion, poor medium permeability of the coating, and peeling off in pieces, and achieve good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

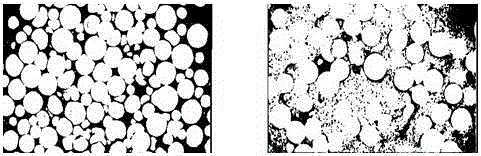

Image

Examples

Embodiment 1

[0025] Mix 9.8kg of vinyl ester resin (WSR-V116, Bluestar Chemical) and 0.18kg of silane coupling agent KH550 and stir for 10-15 minutes to obtain component A;

[0026] 6.5kg of liquid nitrile rubber (40, Lanzhou Petrochemical Technology Company), 4kg of amine curing agent SH-200 curing agent (Guangzhou Xinxi Metallurgical Chemical Co., Ltd.), 0.6kg of accelerator zinc oxide, 40kg of high Aluminum ceramic particles (Al 2 o 3 The content is 60wt%~85wt%, the particle size is 40~70μm), 17kg silicon carbide particles (mixed by 16 mesh, 30 mesh and 240 mesh, of which 16 mesh and 240 mesh particles are mixed in a weight ratio of 2:1, 30 mesh Mix with 240-mesh particles at a weight ratio of 1:2.5), and stir for 10-15 minutes to obtain component B.

[0027] C component: SBS adhesive. You can choose Yuzhu brand universal glue (referred to as Yuzhu glue) from Foshan Yuzhu Chemical Industry Co., Ltd., the main component: SBS (styrene-butadiene-styrene block copolymer) and solvent (tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com