Solid-free recyclable micro-foamed drilling fluid and preparation method thereof

A drilling fluid and solid-free technology, applied in the field of drilling fluid, can solve the problems of complex drilling, oil layer pollution, microbubble temperature resistance, and poor pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

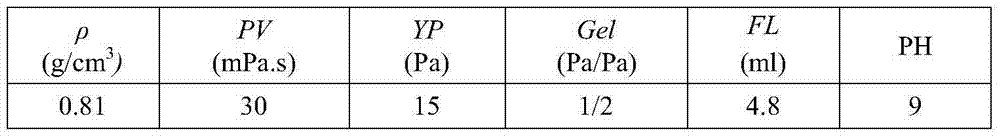

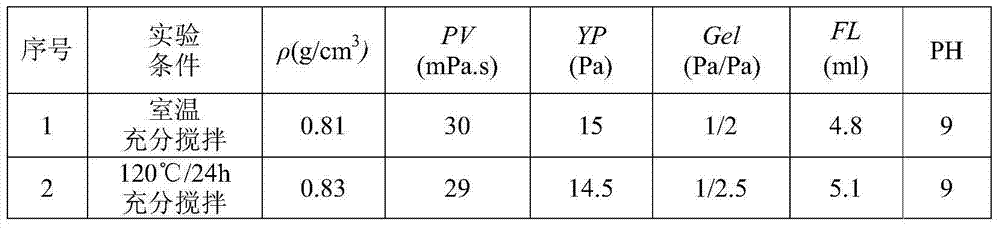

Embodiment 1

[0018] A solid phase-free recirculating microfoam drilling fluid, including: adding 1 gram of NaOH per liter of clear water, 5 grams of xanthan gum XC, 3 grams of polyanionic cellulose PAC, 20 grams of modified starch, and 1 gram of foaming agent BZ - MBS-1, 6 grams of foam stabilizer BZ-MBSF-1, 60 grams of lubricant.

[0019] Wherein, what the modified starch adopts is sodium carboxymethyl starch, and the foaming agent BZ-MBS-1 is sodium lauryl sulfate and sodium dodecyl benzsulfonate with a mass ratio of 6.5:3:0.5. A mixture with sodium tripolyphosphate; the foam stabilizer is a mixture of silicone resin polyether emulsion and lauryl alcohol with a mass ratio of 7:3. The solid-free recyclable microfoam drilling fluid has oil resistance. After the drilling operation, the defoamer BZ-MBDF can be used to defoam, and the density will return to the base fluid density, which can be recycled. The defoamer BZ-MBDF is Dimethicone oil with a viscosity of 300-500mpa.s.

Embodiment 2

[0021] A solid phase-free recirculating microfoam drilling fluid, including: 2 grams of NaOH per liter of clear water, 3 grams of xanthan gum XC, 5 grams of polyanionic cellulose PAC, 10 grams of modified starch, and 6 grams of foaming agent BZ - MBS-1, 1 g of foam stabilizer BZ-MBSF-1, 80 g of lubricant.

[0022] Wherein, what the modified starch adopts is sodium carboxymethyl starch, and the foaming agent BZ-MBS-1 is sodium lauryl sulfate and sodium dodecyl benzsulfonate with a mass ratio of 6.5:3:0.5. A mixture with sodium tripolyphosphate; the foam stabilizer is a mixture of silicone resin polyether emulsion and lauryl alcohol with a mass ratio of 7:3. The solid-free recyclable microfoam drilling fluid has oil resistance. After the drilling operation, the defoamer BZ-MBDF can be used to defoam, and the density will return to the base fluid density, which can be recycled. The defoamer BZ-MBDF is Dimethicone oil with a viscosity of 300-500mpa.s.

Embodiment 3

[0024] A kind of solid phase-free recirculating microfoam drilling fluid, including: adding 1.5 grams of NaOH per liter of clear water, 4 grams of xanthan gum XC, 4 grams of polyanionic cellulose PAC, 15 grams of modified starch, and 2 grams of foaming agent BZ - MBS-1, 5 grams of foam stabilizer BZ-MBSF-1, 70 grams of lubricant.

[0025] Wherein, what the modified starch adopts is sodium carboxymethyl starch, and the foaming agent BZ-MBS-1 is sodium lauryl sulfate and sodium dodecyl benzsulfonate with a mass ratio of 6.5:3:0.5. A mixture with sodium tripolyphosphate; the foam stabilizer is a mixture of silicone resin polyether emulsion and lauryl alcohol with a mass ratio of 7:3. The solid-free recyclable microfoam drilling fluid has oil resistance. After the drilling operation, the defoamer BZ-MBDF can be used to defoam, and the density will return to the base fluid density, which can be recycled. The defoamer BZ-MBDF is Dimethicone oil with a viscosity of 300-500mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com