Multi-flow control valve, chassis outrigger hydraulic control system and crane

A flow control valve and switching quantity control technology, applied in cranes, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of sensitivity, oil pollution, poor reliability, etc., and achieve low oil pollution sensitivity and anti-pollution. The effect of strong ability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

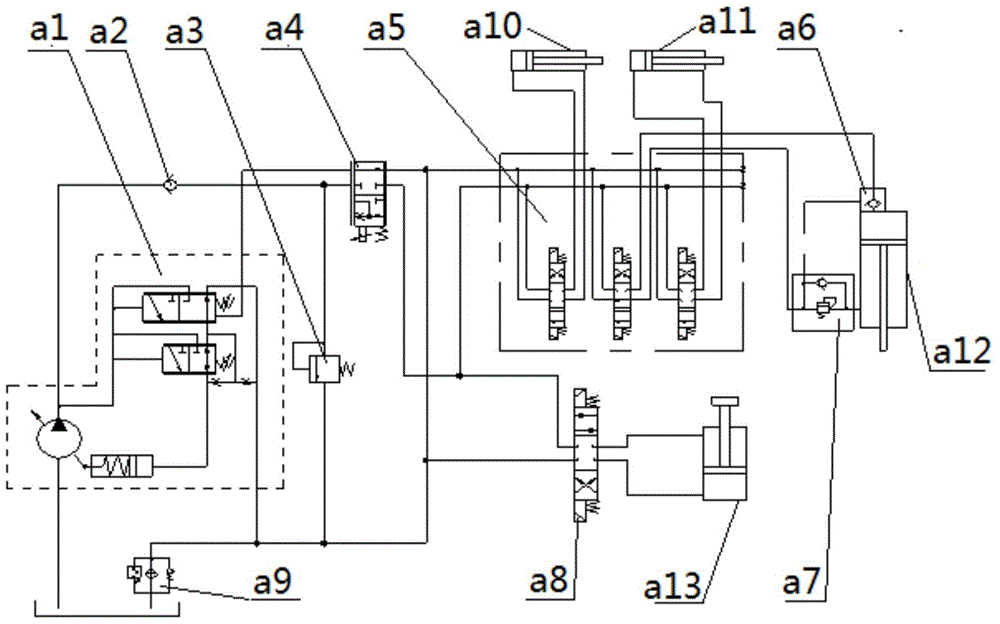

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0025] The existing proportional reversing valve is responsible for two functions in the load sensing system, one is to switch the supply oil of the actuator with different flow requirements, and the other is to control the valve diameter, so that through the proportional reversing The oil flow of the valve corresponds to the demand of the corresponding actuator. However, it has also been analyzed that the proportional directional valve itself has problems such as high cost, poor reliability, and inaccurate diameter control.

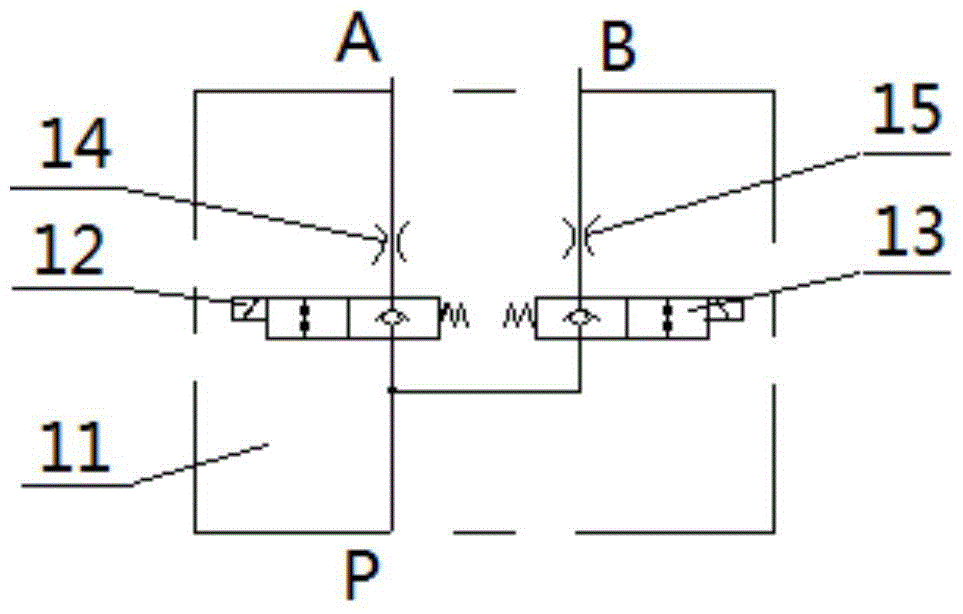

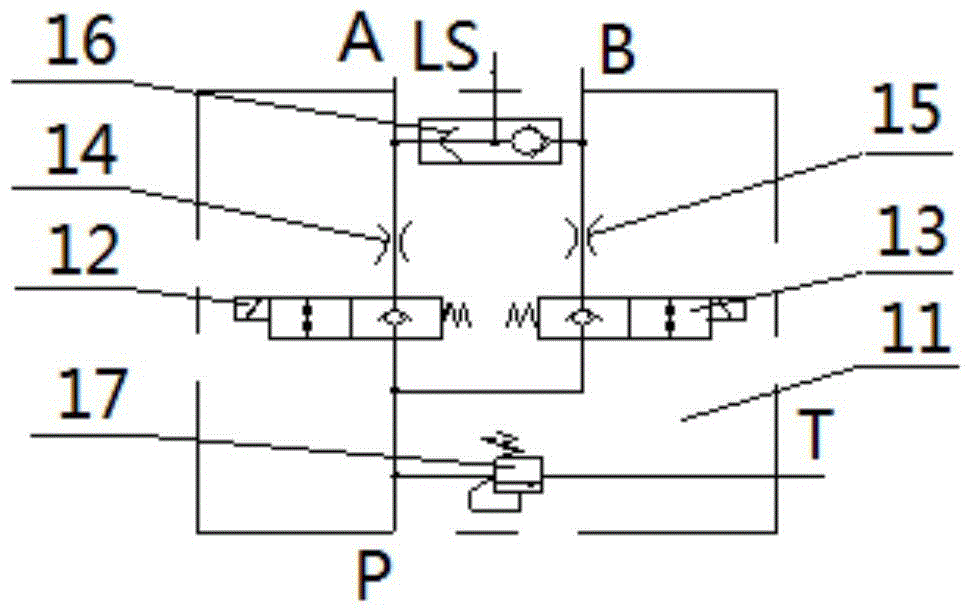

[0026] For these problems, the inventor realizes these two aspects in the multi-flow control valve through different components, so as to eliminate the problems caused by the defects of the proportional reversing valve itself. For the oil supply switching problem of different actuators, switch c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com