Wet-film surface air cooler of composite structure

A technology of composite structure and surface cooler, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of unreliable operation, low effective utilization rate, large volume increase, etc., to overcome the structure of surface cooler Frost, simple structure, avoid frosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

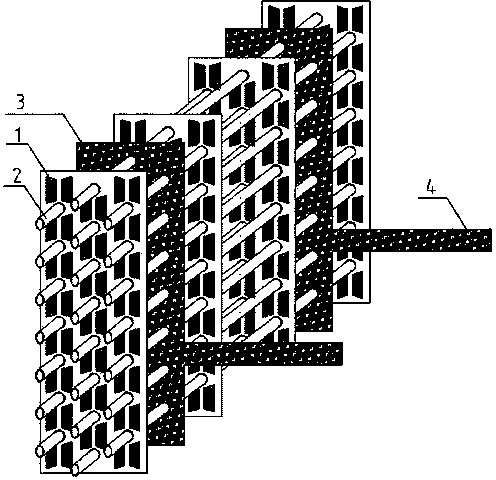

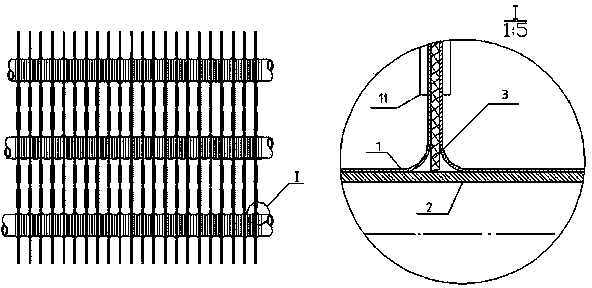

[0043] refer to figure 1 and figure 2 , the composite structure wet film surface cooler provided in this embodiment includes a plurality of fins 1 arranged in parallel at intervals and a plurality of heat exchange tubes 2 passing through the fins 1, and the heat exchange tubes 2 contain flowing refrigerant; A wet film layer 3 is pressed between the two fins 1 to form a "sandwich" structure; the dimensions of the wet film layer 3 are basically the same as those of the fins 1, so that the fins 1 are completely covered by the wet film layer 3 and in close contact, ensuring Moisture infiltrates to the entire surface of each fin 1 naturally, evenly and quickly without any power. A water-absorbing belt 4 for introducing water into the wet film layer 3 extends outward from the middle and lower side of the wet film layer 3, so as to ensure that the water will not drip out from the wet film layer 3 when the air conditioner is not turned on. Covered with wet film layer 3. Among them...

Embodiment 2

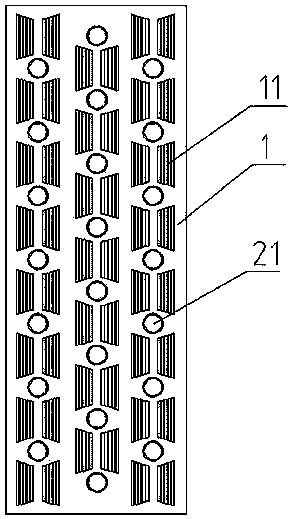

[0060] The difference from Example 1 is that the wet film layer 3 is uniformly distributed on one side of each fin 1 in strip shape, and the wet film layers 3 of all fins 1 can be arranged on the same side or on different sides.

Embodiment 3

[0062] The difference from Example 1 is that in some of the fins 1, a wet film layer 3 is pressed between two adjacent fins 1 to form a "sandwich" structure; in the other part of the fins 1, one part of each fin 1 The side is pressed with a wet film layer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com