Method for generating three-dimensional model of corrugation structure of dragonfly wing

A 3D model and technology of dragonfly, which is applied in the field of 3D model generation of dragonfly wing fold structure, can solve the problems of measurement result influence, dragonfly wing deformation, complicated preparation process, etc., and achieve improved light reflection ability, convenient operation process and accurate scanning data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

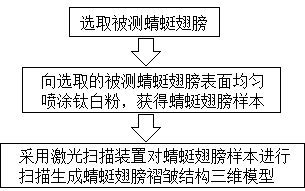

[0023] Such as figure 1 As shown, the present invention designs a method for generating a three-dimensional model of a dragonfly wing fold structure, a method for generating a three-dimensional model of a dragonfly wing fold structure, comprising the following steps:

[0024] Step 01. Select the dragonfly wings to be tested;

[0025] Step 02. Spray titanium dioxide evenly on the surface of the selected dragonfly wings to obtain dragonfly wing samples;

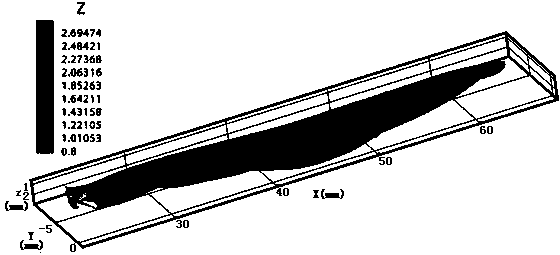

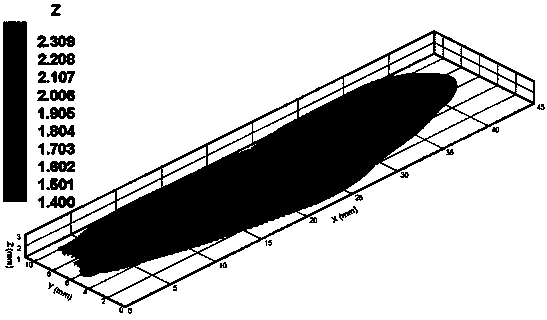

[0026] Step 03. Use a laser scanning device to scan the dragonfly wing sample to generate a three-dimensional model of the dragonfly wing fold structure.

[0027] Based on the steps of the above design technical scheme, the method for generating the three-dimensional model of the dragonfly wing wrinkle structure designed by the present invention is based on the existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com