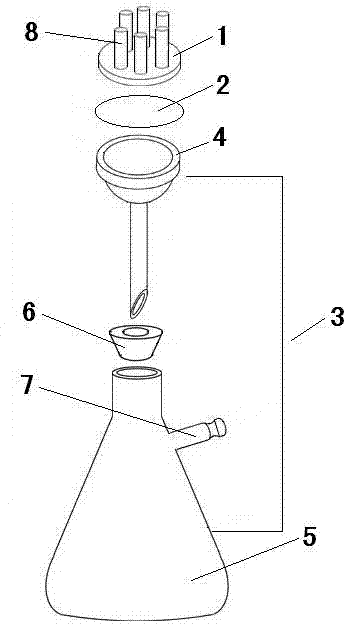

Multichannel membrane enrichment device

A multi-channel, membrane enrichment technology, applied in the field of sample pretreatment of analytical chemistry, can solve the problems affecting the repeatability of the membrane enrichment process, poor uniformity of the filter membrane, etc., to achieve convenient number, improve repeatability, and large enrichment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Using the multi-channel membrane enrichment device of the present invention to enrich, the steps are:

[0043] (1) Place the mixed cellulose enrichment filter membrane 2 with a pore size of 0.22 μm and a diameter of 50 mm on the sand core structure at the upper end of the microporous filter element 4 of the filtrate collection container 3 . The diameter of the sand core structure is 40 mm and the pore size is 20 μm.

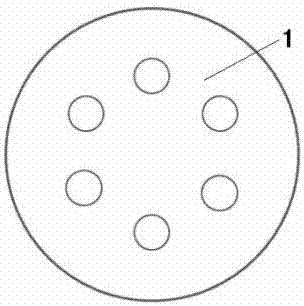

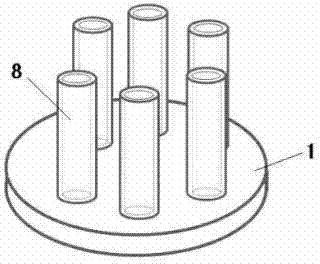

[0044] (2) Put the multi-channel input device 1 with 6 holes (7 mm in diameter) on the enrichment filter membrane 2 through the smooth side, and fix it with a magnetic device.

[0045] (3) Use Tris-HCl and NaOH with a pH of 9.0 to adjust the pH of 6 parts of 50 mL divalent cobalt ion solution with a concentration of 1 to 30 μg / L to 9.0, and add 100 uL with a concentration of 10 -3 mol / L PAN, magnetically stirred for 7 minutes to fully react PAN with divalent cobalt ions to obtain a sample solution.

[0046] The sample solution is respectively injected into ...

Embodiment 2

[0050] Using the multi-channel membrane enrichment device of the present invention to enrich, the steps are:

[0051] (1) Put the mixed cellulose enrichment filter membrane 2 with a pore size of 0.1 μm and a diameter of 60 mm on the sand core structure at the upper end of the microporous filter element 4 of the filtrate collection container 3 . The diameter of the sand core structure is 50 mm and the pore size is 10 μm.

[0052] (2) Put the multi-channel input device 1 with 50 holes (3 mm in diameter) on the enrichment filter membrane 2 through the smooth side, and fix it with clips.

[0053] (3) Insert 50 connecting pipes 8 (plastic hoses) connected to the multi-channel input device 1 into 50 parts of 10mL rhodamine B sample solution with a concentration of 1-500μg / L and pH=1.0, and turn on the vacuum pump . Under the action of the vacuum pump, the sample solution is sucked into the multi-channel input device 1 and enters the filtrate container 5 through the enrichment filte...

Embodiment 3

[0057] Using the multi-channel membrane enrichment device of the present invention to enrich, the steps are:

[0058] (1) Put the nylon microporous enrichment filter membrane 2 with a pore size of 0.22 μm and a diameter of 60 mm on the sand core structure at the upper end of the microporous filter element 4 of the filtrate collection container 3. The diameter of the sand core structure is 50 mm and the pore size is 20 μm.

[0059] (2) Put the multi-channel input device 1 with 20 holes (aperture diameter: 5 mm) on the enrichment filter membrane 2 through the smooth side, and fix it with clips.

[0060] (3) Insert 20 connecting pipes 8 (plastic hoses) connected to the multi-channel input device 1 into 20 parts of 10mL 2-naphthalenesulfonic acid sample solution with a concentration of 1-300μg / L and pH=3.5, Turn on the vacuum pump. Under the action of the vacuum pump, the sample solution is sucked into the multi-channel input device 1 and enters the filtrate container 5 through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com