A kind of dust removal equipment

A technology for dust removal equipment and filter elements, which is used in the separation of dispersed particles, chemical instruments and methods, and combined devices, etc., can solve the problems of gas that is difficult to meet standards, affect product quality, and large cleaning workload, so as to improve the filtering effect and service life. , Enhance the effect of dust removal and filtration, and reduce the effect of filtration burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

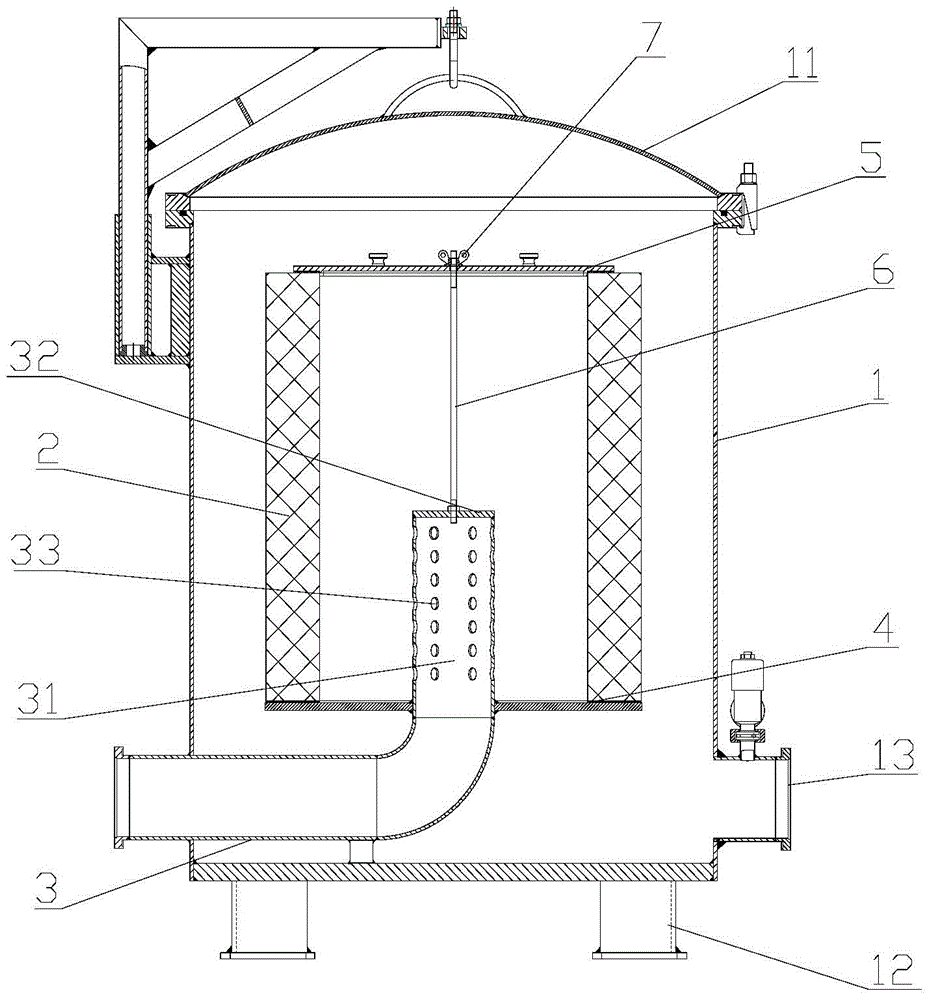

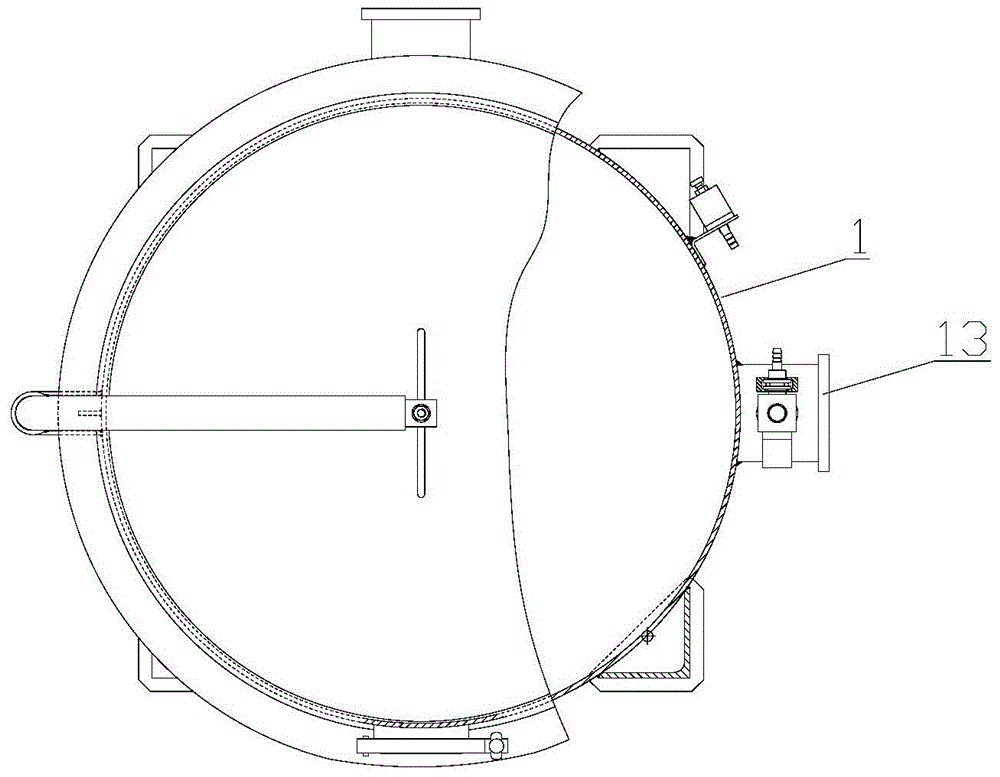

[0032] Please refer to figure 1 , figure 2 , figure 1 It is a schematic structural diagram of a specific implementation of the dust removal equipment provided by the present invention; figure 2 for figure 1 Top view.

[0033] As shown in the figure, in one embodiment, the dust removal equipment provided by the present invention is a single crystal furnace dust remover, which is used to treat the exhaust gas discharged from the single crystal furnace during the production of single crystal silicon, and is mainly composed of a housing 1 and a filter element 2. It consists of two parts.

[0034] The housing 1 is cylindrical, with a circular upper cover 11 that can be opened and closed at the top, feet 12 at the bottom, and other accessory p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com