Process method for treating electroplating comprehensive wastewater

A comprehensive technology of process method and electroplating, applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high cost, environmental pollution, etc., to eliminate pollution, facilitate workers to operate, and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

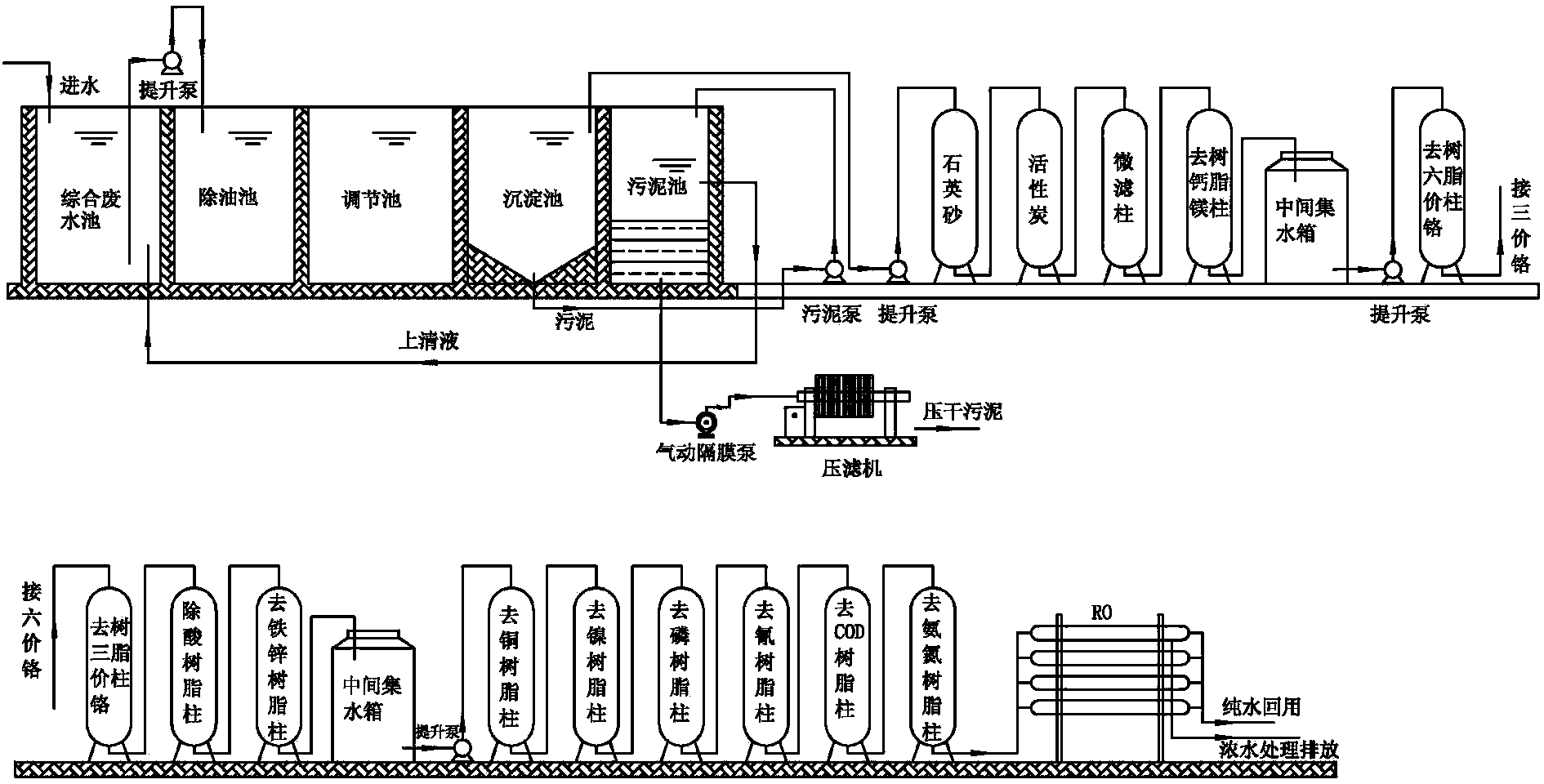

[0024] In order to better illustrate the present invention, further description will now be made in conjunction with the accompanying drawings.

[0025] A process for treating comprehensive electroplating wastewater, comprising the following steps:

[0026] a. Wastewater from all channels is discharged to the comprehensive wastewater pool, and then pumped to the degreasing tank. A grid is set at the entrance of the degreasing tank. The waste water passes through the degreasing tank to remove most of the slick oil, and then enters the sedimentation tank through the regulating tank. After a few hours of natural sedimentation in the sedimentation tank, some large suspended solids and other impurities can be removed; a small amount of sludge generated in the sedimentation tank is pumped into the sludge tank through the sludge pump, and after being treated in the sludge tank, the The supernatant is discharged into the comprehensive waste water pool for further treatment;

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com