Method for photocatalytically degrading lignin by hydrotalcite-like compound

A technology for catalytic degradation and lignin, applied in the field of hydrotalcite-like photocatalytic degradation of lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

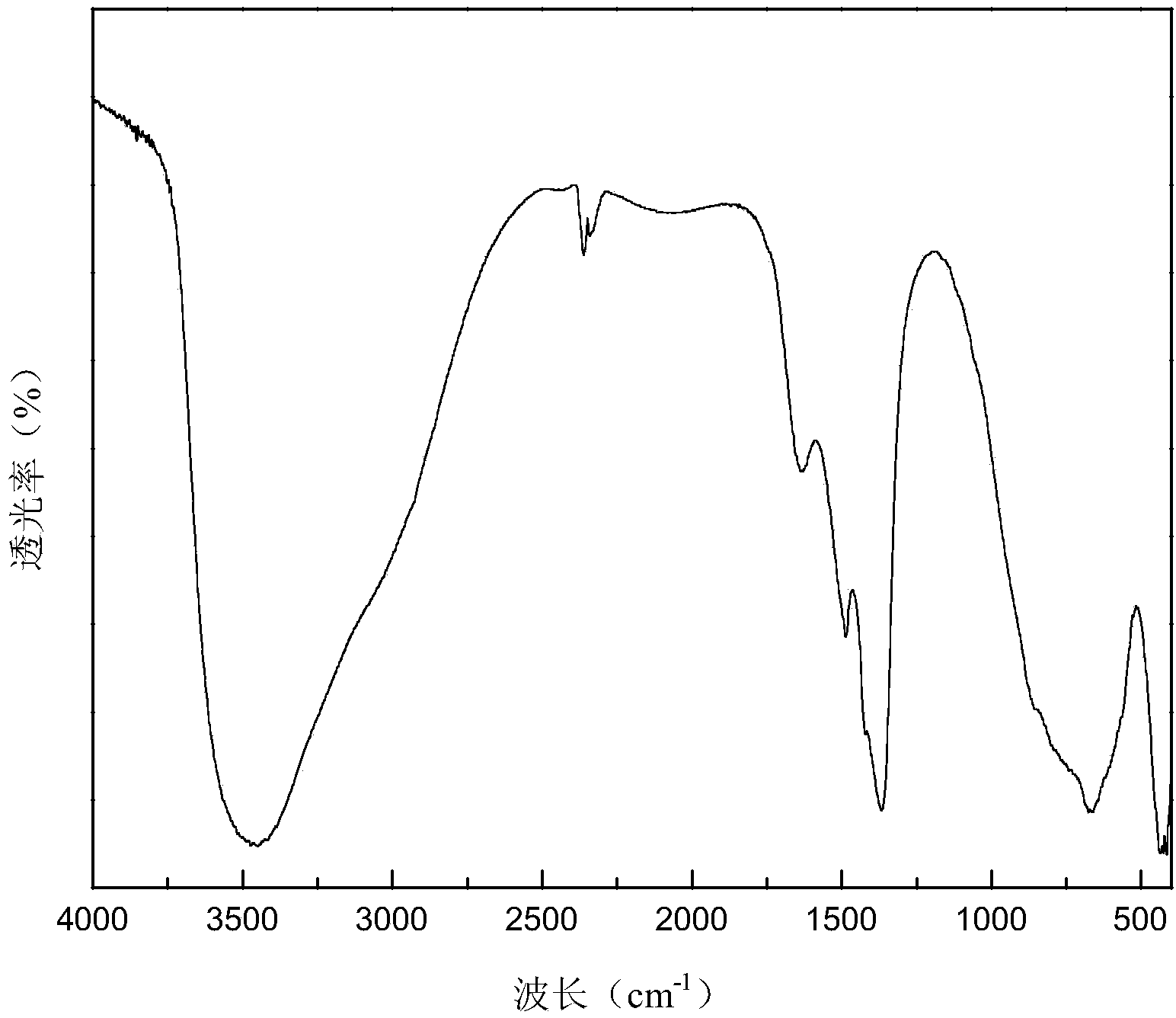

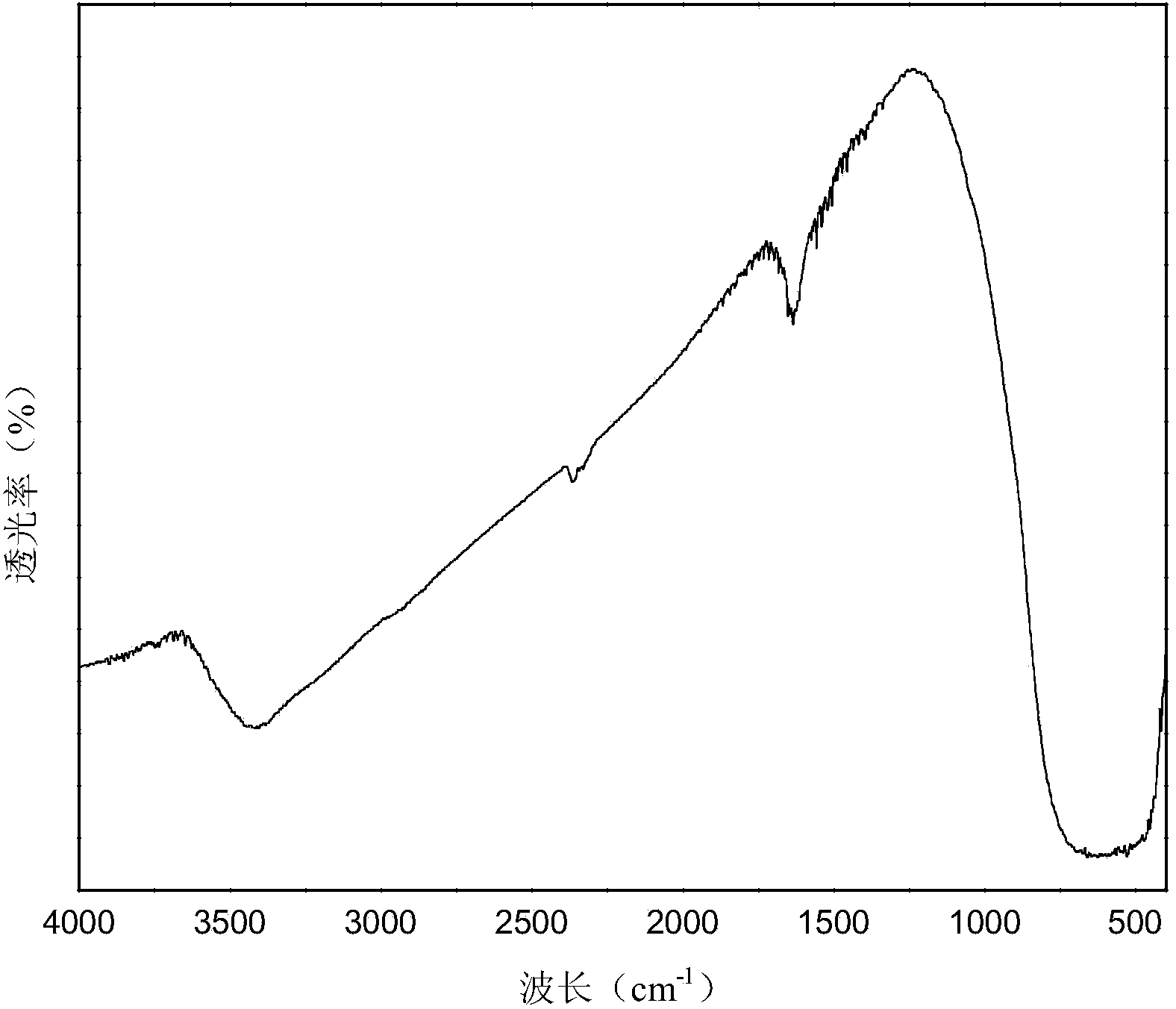

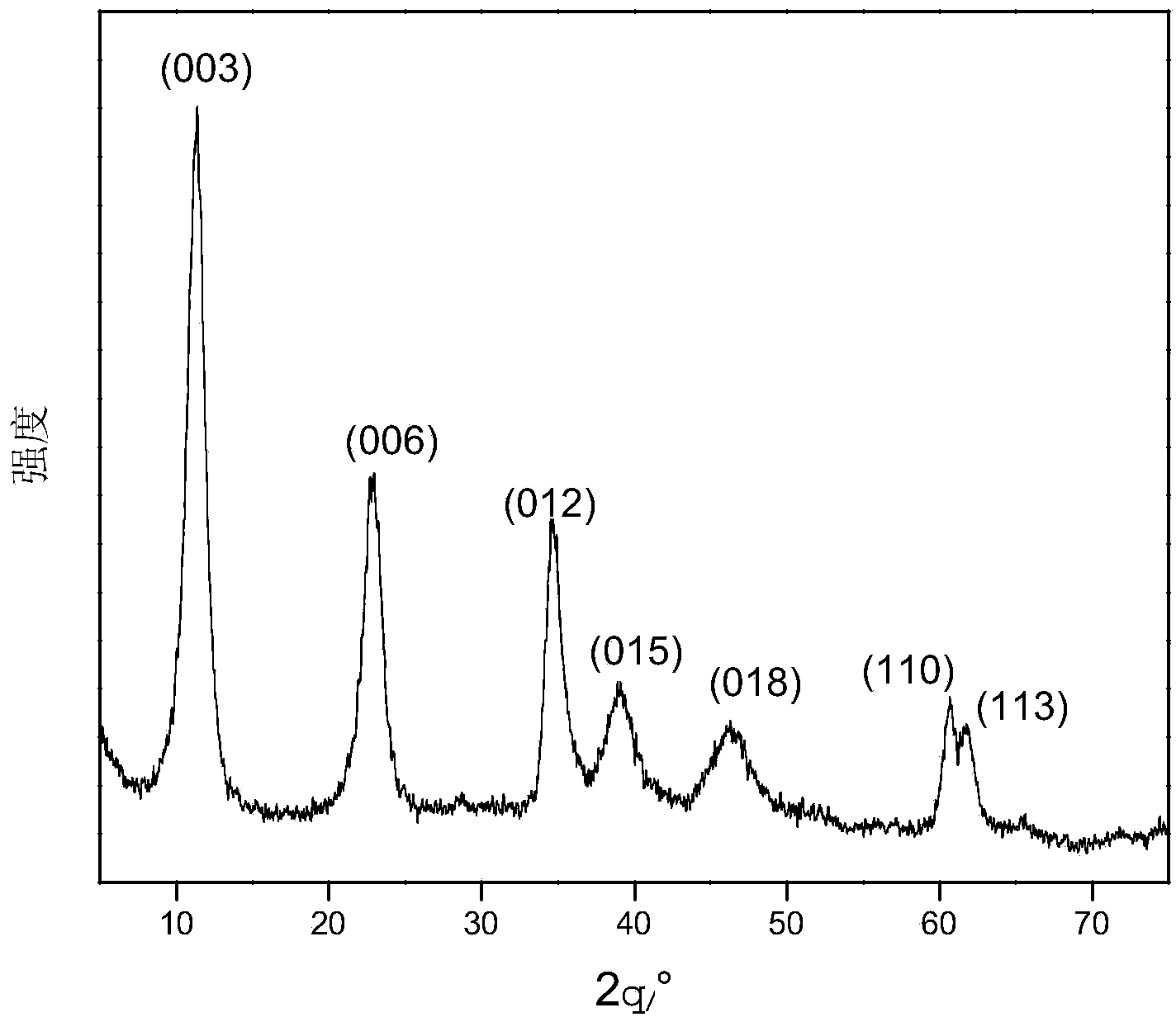

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: The method for degrading lignin by hydrotalcite-like hydrotalcites in this embodiment is as follows: 3mg nickel-magnesium-aluminum hydrotalcites are placed in a quartz glass tube, and 60mL concentration of 0.15g / L alkali lignin solution is added, and the light intensity Irradiate under 50W fluorescent lamp for 20 hours to complete lignin degradation.

specific Embodiment approach 2

[0012] Specific embodiment two: the specific method of hydrotalcite-like degradation lignin method in the present embodiment is as follows: 9mg nickel-magnesium-aluminum-like hydrotalcites are placed in the quartz glass tube, add 60mL concentration and be 0.15g / L alkali lignin solution, light intensity Irradiate under 50W fluorescent lamp for 20 hours to complete lignin degradation.

specific Embodiment approach 3

[0013] Specific implementation mode three: the method for degrading lignin by hydrotalcite-like in this embodiment is as follows: 15mg nickel-magnesium-aluminum hydrotalcite is placed in a quartz glass tube, adding 60mL concentration is 0.15g / L alkali lignin solution, light intensity Irradiate under 50W fluorescent lamp for 20 hours to complete lignin degradation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com