Process for high speed railway ballastless track construction

A ballastless track and high-speed railway technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of inaccessible high-speed railway construction, complex construction technology, expensive equipment, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

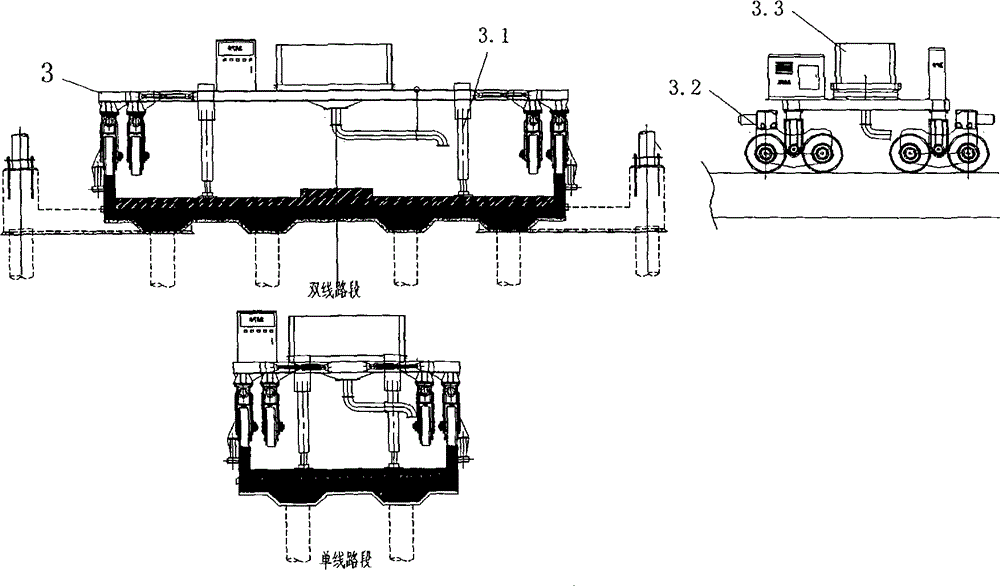

[0038] Such as Figure 4 A process for the construction of high-speed railway ballastless track is shown, including construction preparation; measurement and setting out; laying of steel bars at the bottom of the ballast bed; installation of longitudinal formwork; Binding; fine adjustment of rail row; concrete pouring; vibrating, plastering, forming; ballast bed maintenance; dismantling and transferring of machinery and tools.

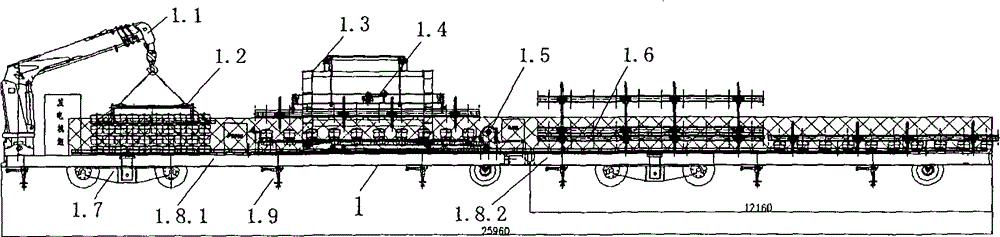

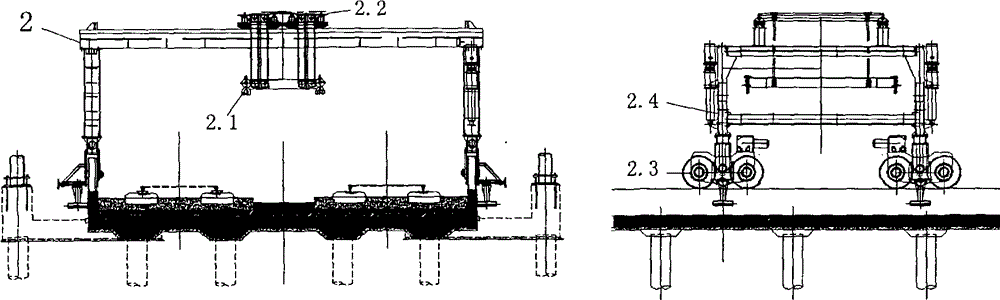

[0039] Such as figure 1 , figure 2 , image 3 As shown, the construction preparation includes: raw material entering and storing; pier settlement assessment; concrete mix ratio design; engineering and technical personnel to review the construction drawings of ballastless track; training for construction personnel and technical personnel; formulating construction safety assurance measures And complete the implementation of ballastless track construction organization design and construction operation instructions; the main construction equipment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com